Speed reducer capable of automatically judging faults, elevator and automatic fault judging method

A technology of reducer and deceleration transmission, which is applied in the field of fault identification, and can solve problems such as the inability to distinguish the amount of vibration, signal endpoint decomposition error, and poor noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

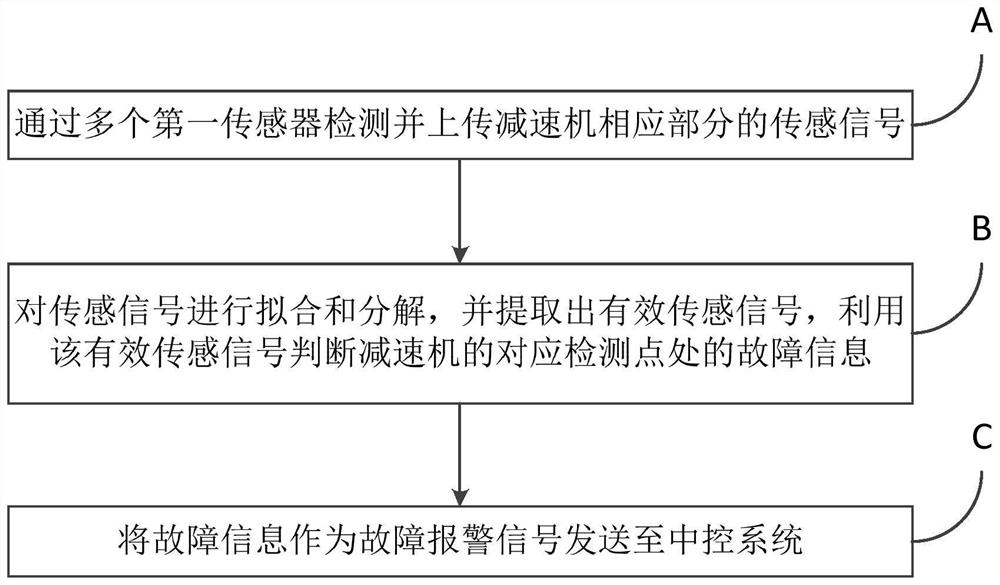

[0078] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

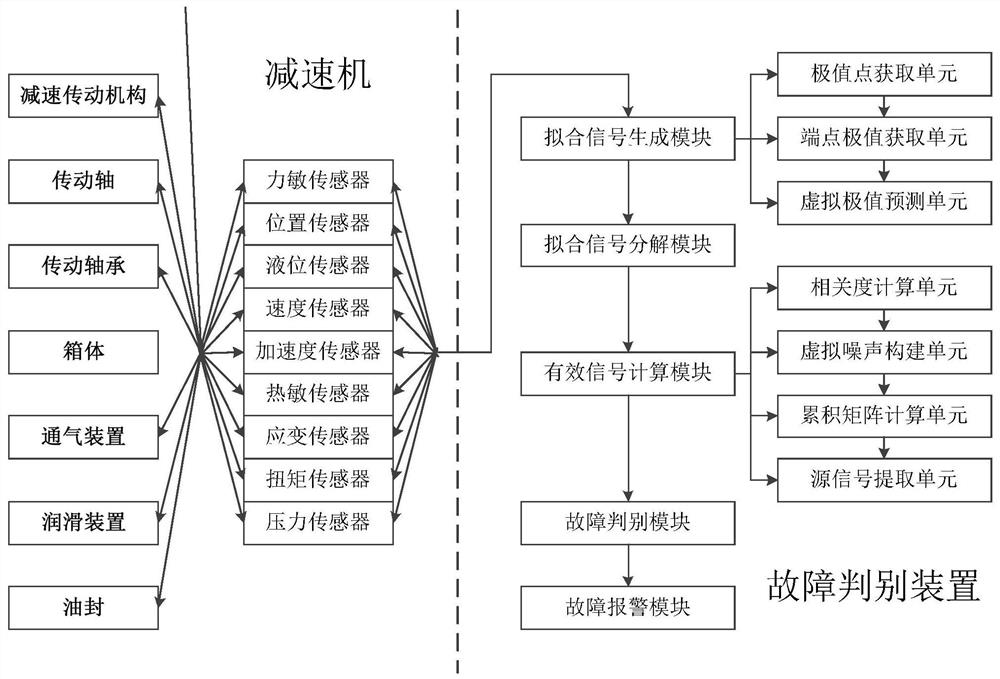

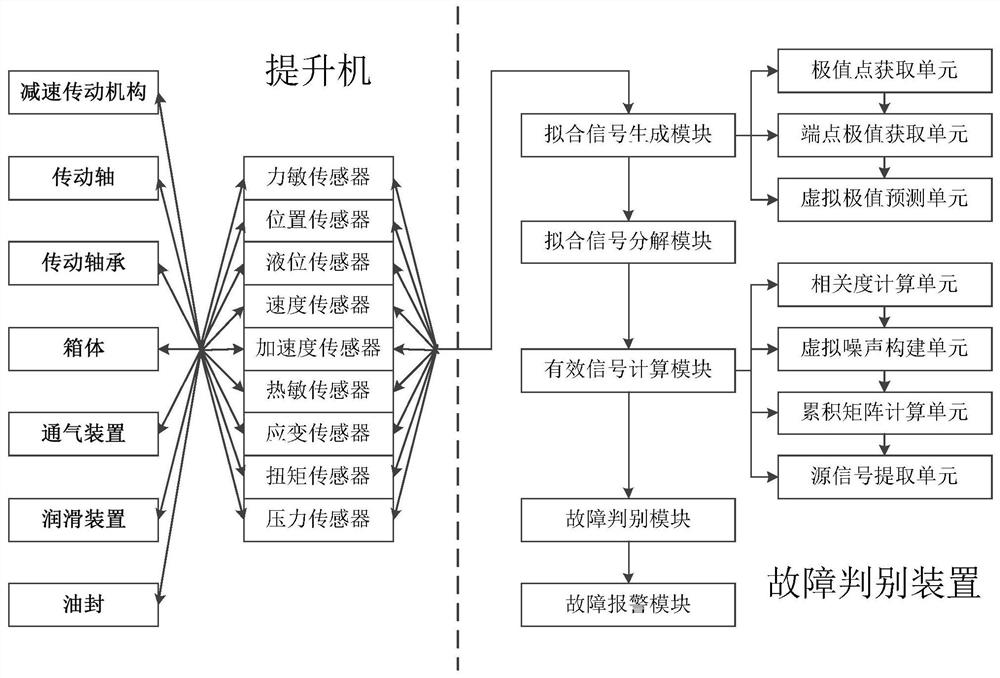

[0079] Refer below figure 1 The first embodiment of the reducer for automatically identifying faults disclosed in the present application will be described in detail. Such as figure 1 As shown, this embodiment mainly includes: a reduction transmission mechanism, a transmission shaft, a transmission bearing, a casing, a ventilation device, a lubricating device, an oil seal, an automatic fault discrimination device and a plurality of first sensors.

[0080] A plurality of first sensors are installed on at least one part of the reduction transmission mechanism, transmission shaft, transmission bearing, box body, ventilation device, lubricating device, and oil seal, and are used to detect and upload sensing sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com