Ground wire assembling and disassembling system and method

A grounding wire, assembly and disassembly technology, applied in the direction of connection/disconnection of connection devices, wire-wound connectors, etc., can solve problems such as risk, inconvenience and safety, and achieve the effect of reducing risk, simple operation and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

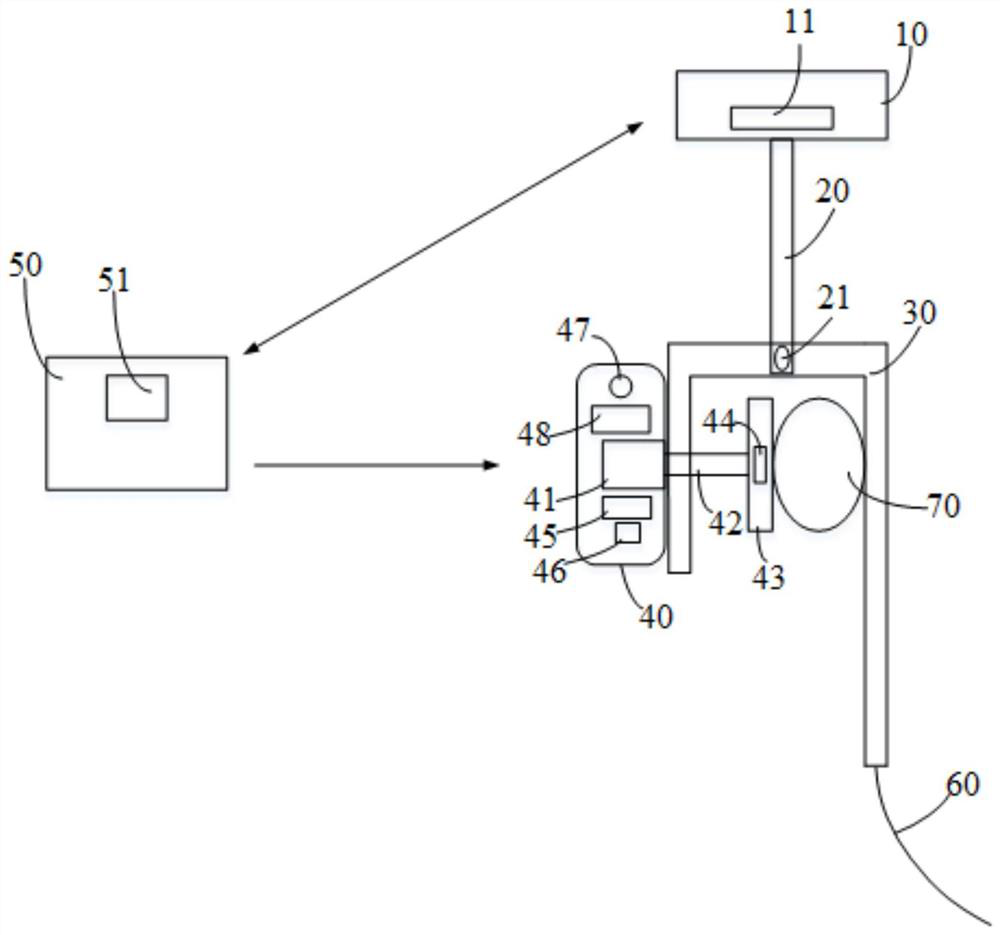

[0044] The installation and disassembly system of a grounding wire provided by this embodiment, such as figure 1 As shown, it includes a drone 10, a telescopic assembly 20, a metal hook 30, an automatic tightening device 40, a remote control device 50, and a grounding wire 60, wherein the drone 10 is used to transport the grounding wire 60 to the wire that needs the grounding wire 60 At 70, the UAV 10 is equipped with a camera 11 for real-time shooting of images, which is convenient for maintenance personnel to operate the assembly and disassembly system. The telescopic assembly 20 is installed on the UAV 10 to move the ground wire 60 closer to or away from the wire 70. The metal hook 30 is detachably connected to the telescopic assembly 20 and can be driven and moved by the telescopic assembly 20, and is connected with a grounding wire 60 for the conduction between the grounding wire 60 and the wire 70, and the automatic tightening device 40 is installed on the metal hook 30. ...

Embodiment 2

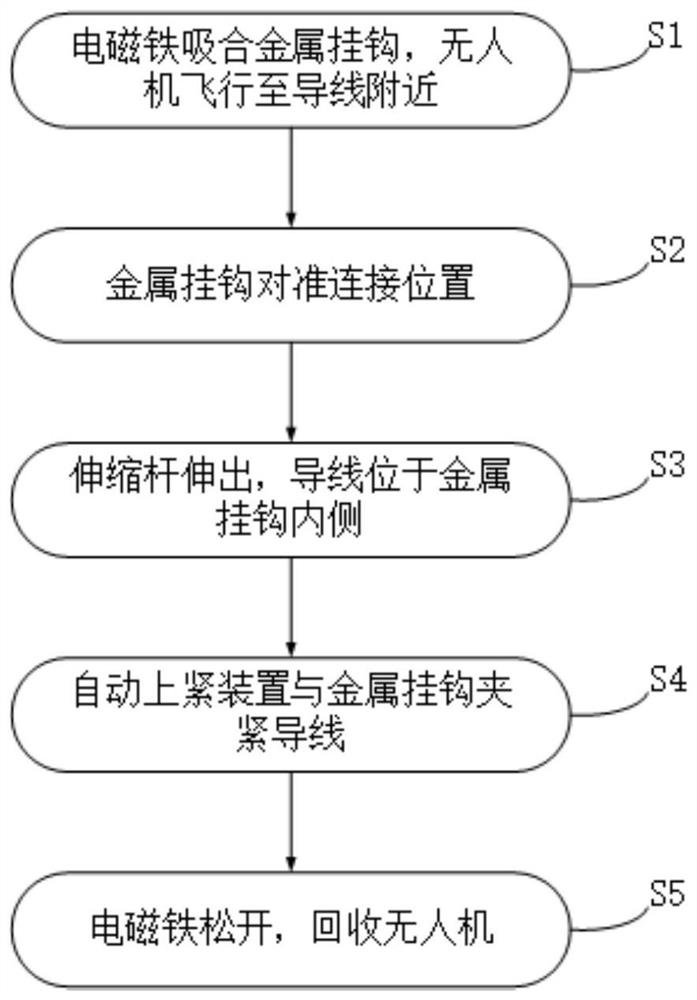

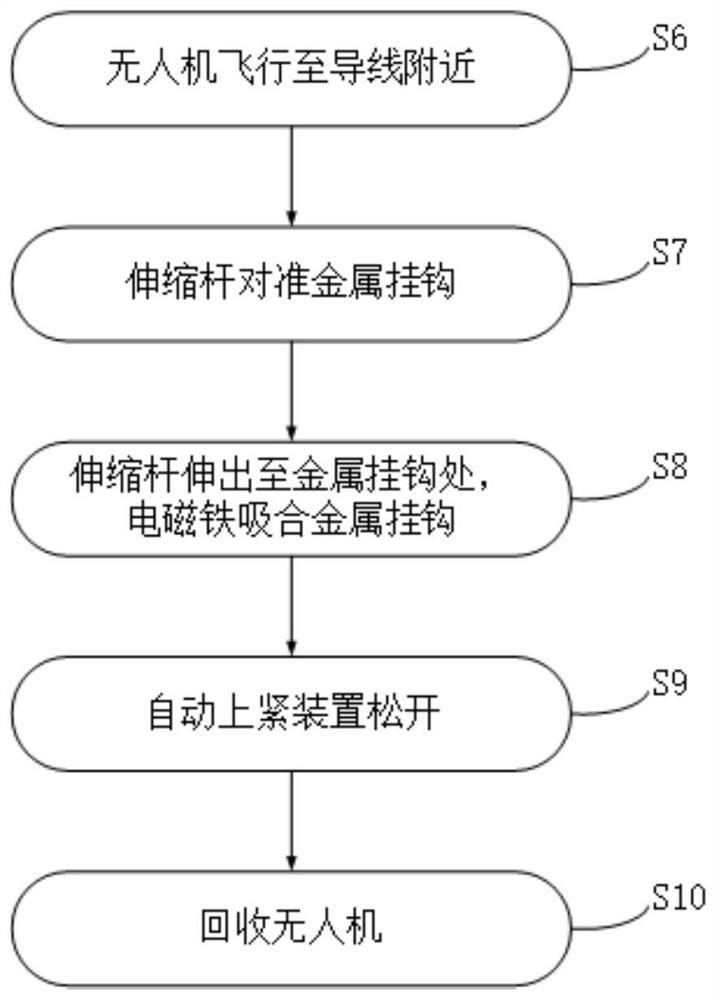

[0051] This embodiment provides a ground wire assembly and disassembly method, which is implemented by the ground wire assembly and disassembly system of Embodiment 1, including the installation method of the ground wire 60, such as figure 2 As shown, the installation method specifically includes the following steps:

[0052] S1: The electromagnet 21 is energized by the remote control device 50 so that the electromagnet 21 attracts the metal hook 30 , and then the drone 10 is controlled by the remote control device 50 to fly above the wire 70 that needs to be connected to the ground wire 60 .

[0053] That is to say, in this step, the drone 10 sucks the metal hook 30 connected to the ground wire 60 and brings it to the top of the wire 70 that needs to be connected to the ground wire 60. At this time, the position of the drone 10 is not accurately positioned. .

[0054] S2: Obtain the image information of the connection position where the wire 70 is connected to the metal hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com