Axial rotor of axial gap type rotating motor

A technology of rotating electrical machines and axial gaps, applied in the field of rotors, can solve problems such as rotor magnets flying off, and achieve the effect of increasing reluctance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

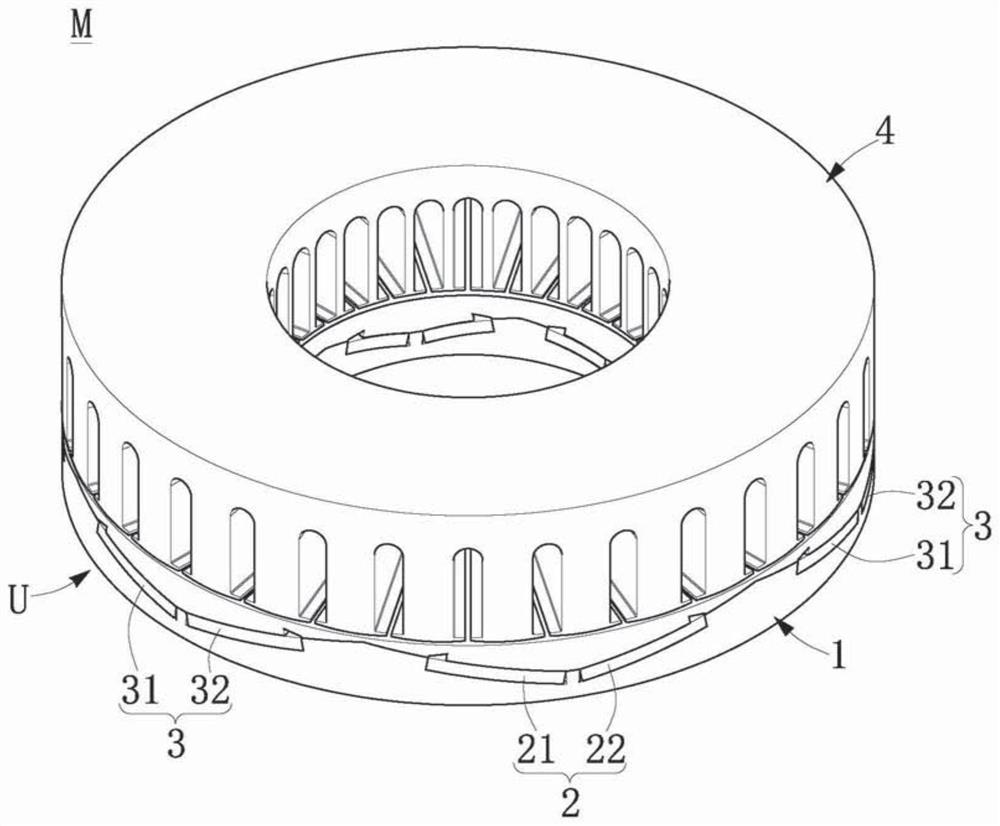

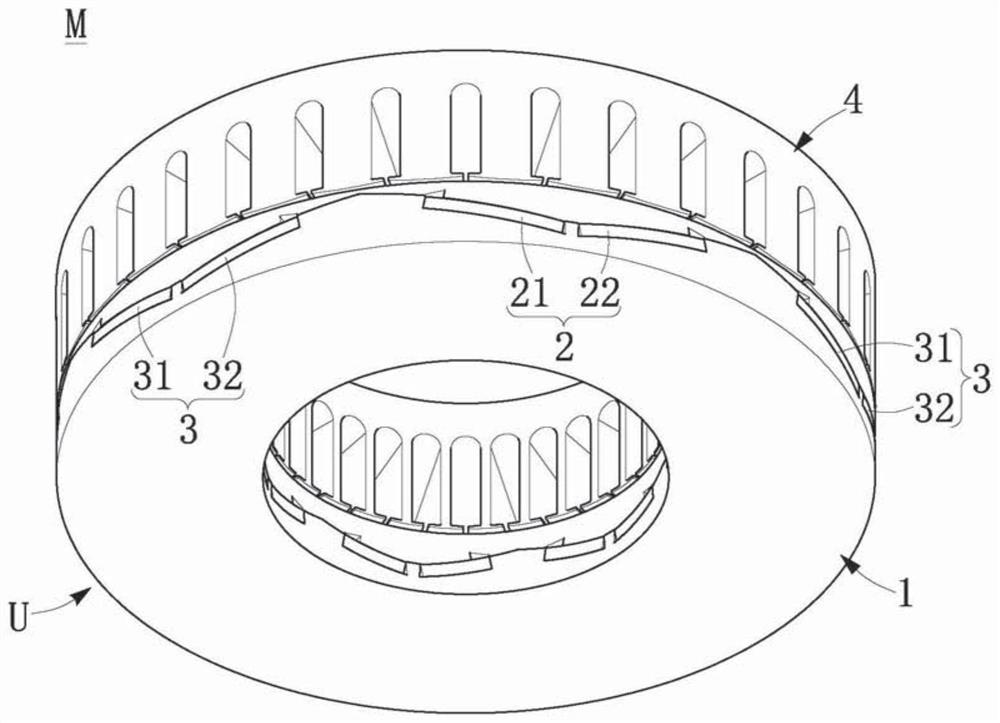

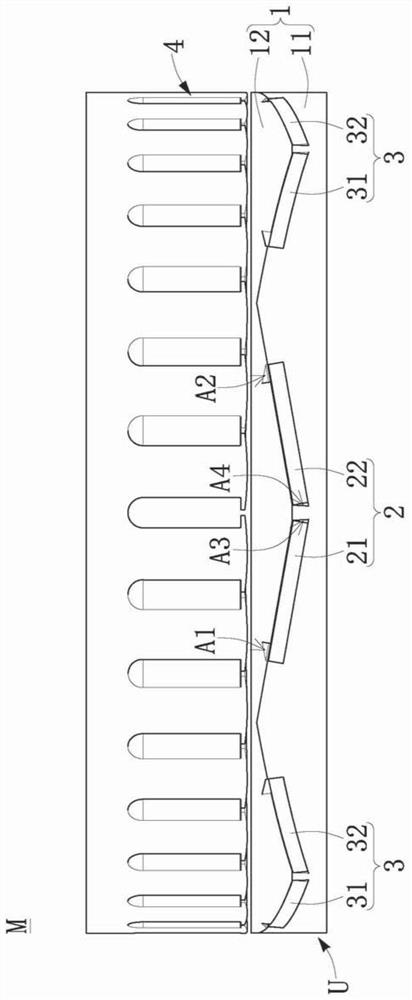

[0033] First, see figure 1 and figure 2 as shown, figure 1 and figure 2 They are three-dimensional schematic diagrams of axial gap rotating electrical machines according to embodiments of the present invention. The present invention provides an axial rotor U of an axial gap type rotating electrical machine M, that is, a rotor structure applicable to an axial electric motor. The axial gap type rotating electrical machine M may include a central shaft (not shown in the figure), at least one axial stator 4 and at least one axial rotor U. The axial rotor U can be arranged corresponding to the axial stator 4 so that the axial rotor U can rotate relative to the axial stator 4 .

[0034] Based on the above, further speaking, the axial rotor U may include: an annular disk structure 1 and a plurality of magnetic element groups. A plurality of magnetic element groups can be disposed on the annular disk structure 1 , and the plurality of magnetic element groups surround a central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com