Anti-choking feeding bottle

A feeding bottle and anti-choking technology, applied in feeding bottles, climate sustainability, biological packaging, etc., can solve problems such as affecting the normal feeding of infants, prone to coughing, choking, and milk entering the lungs, etc. The volume is reduced, the dissolution rate is improved, and the effect of avoiding milk choking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

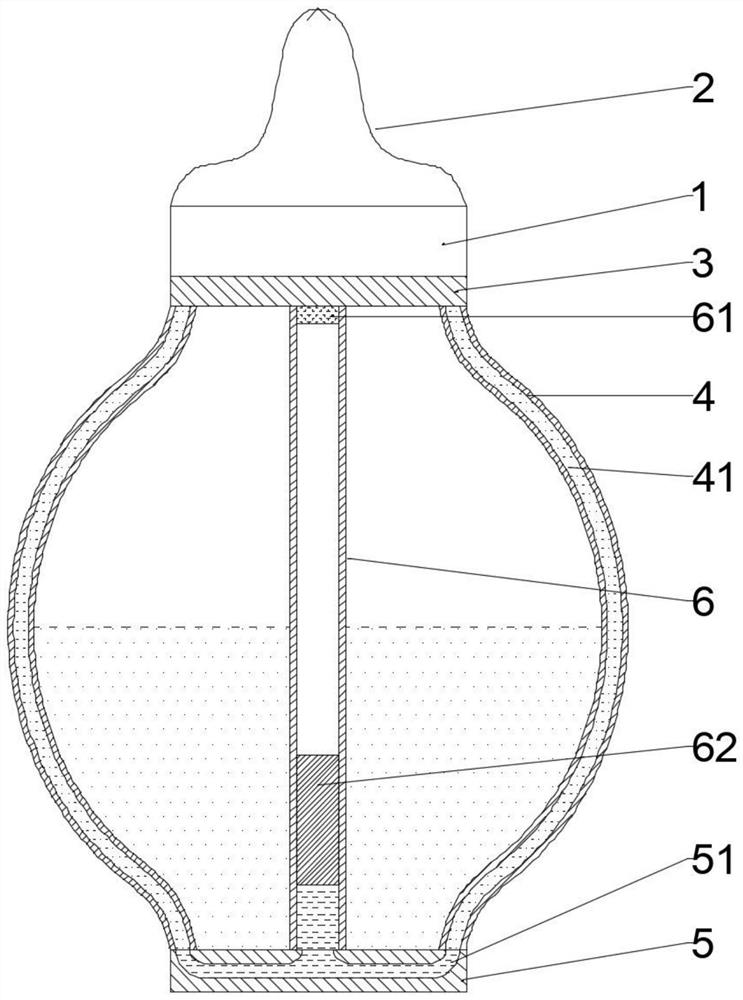

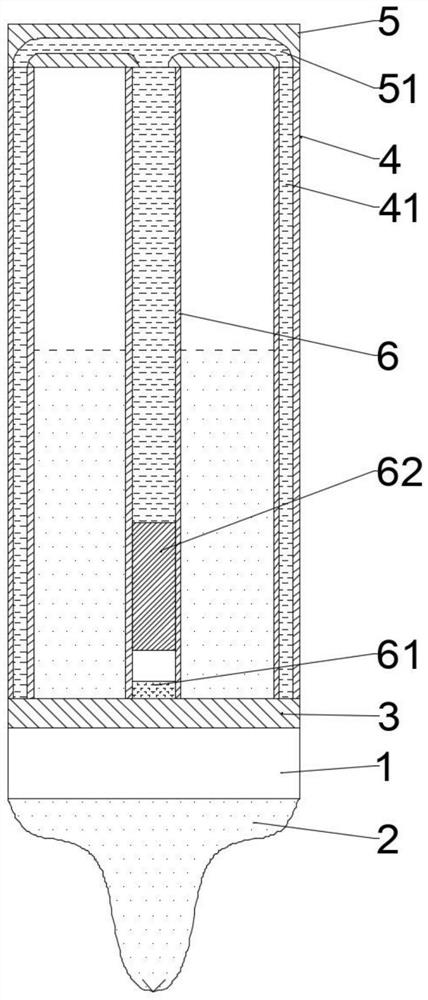

[0028] Example: see figure 1 , figure 2 , an anti-choking feeding bottle, comprising a bottle body, a cover body 1 and a glue head 2; the glue head 2 is provided with a nipple 21, and no air return hole is arranged;

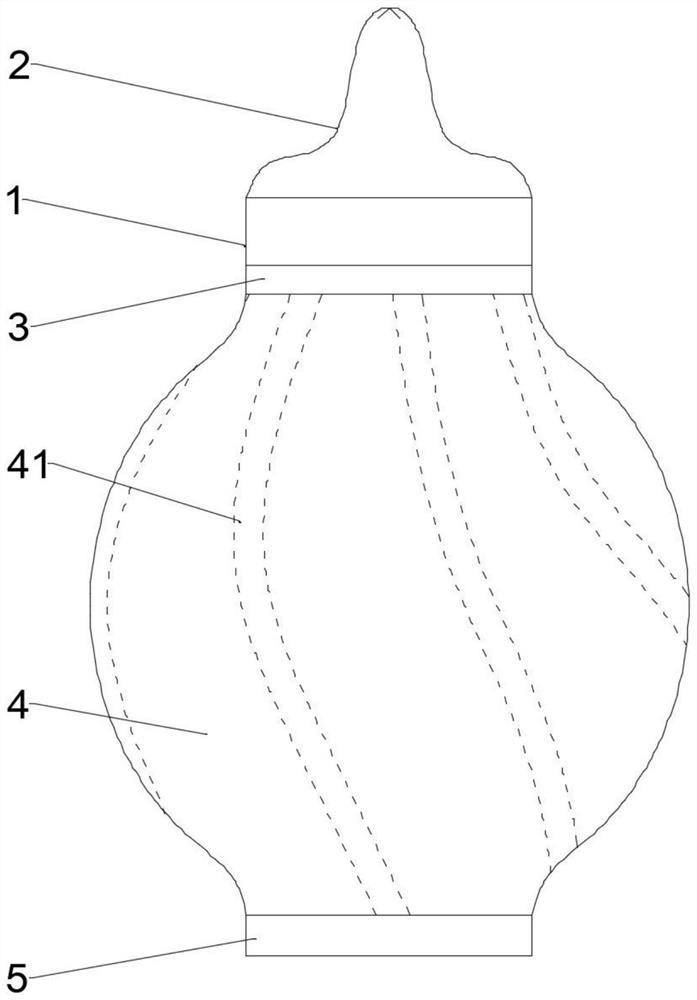

[0029] Described bottle body comprises bottleneck 3, bottle bottom 5 and a variable-shaped bottle body 4; Described bottle body 4 is made of elastic silica gel material, offers hollow pipe in bottle body 4 to form shaping tube 41; Tubes 41 are equidistantly distributed in the circumferential direction of the bottle body, and each shaped tube 41 extends along a direction parallel to the axis of the bottle body. The upper end of the shaped tube 41 is closed and extends to the bottleneck 3, and the lower end of the shaped tube 41 extends to the bottle neck Bottom 5 is also communicated with the guide channel 51 arranged at the bottom of the bottle;

[0030] The bottle neck 3 is detachably connected and fixed with the cover body 1, and an adjustment cylinder 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com