Rice screening device with dust removal function

A screening device and technology for rice, which are applied in sieves, grilles, and the separation of solids from solids by airflow, can solve the problems of inconvenient rice screening and inconvenient replacement of screens, and achieve the effect of promoting screening and ensuring the effect of dust removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

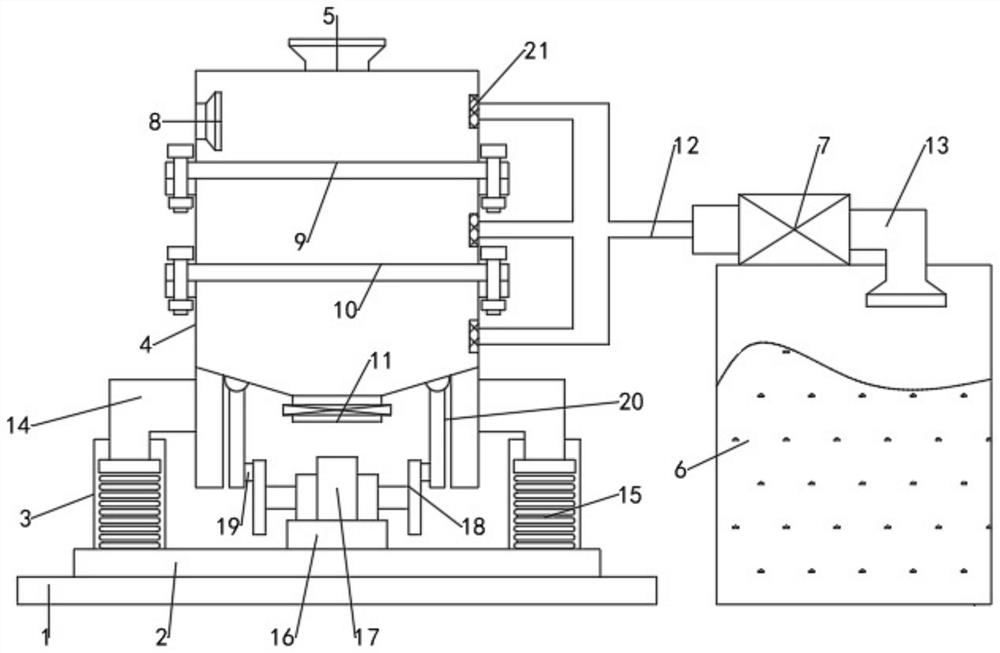

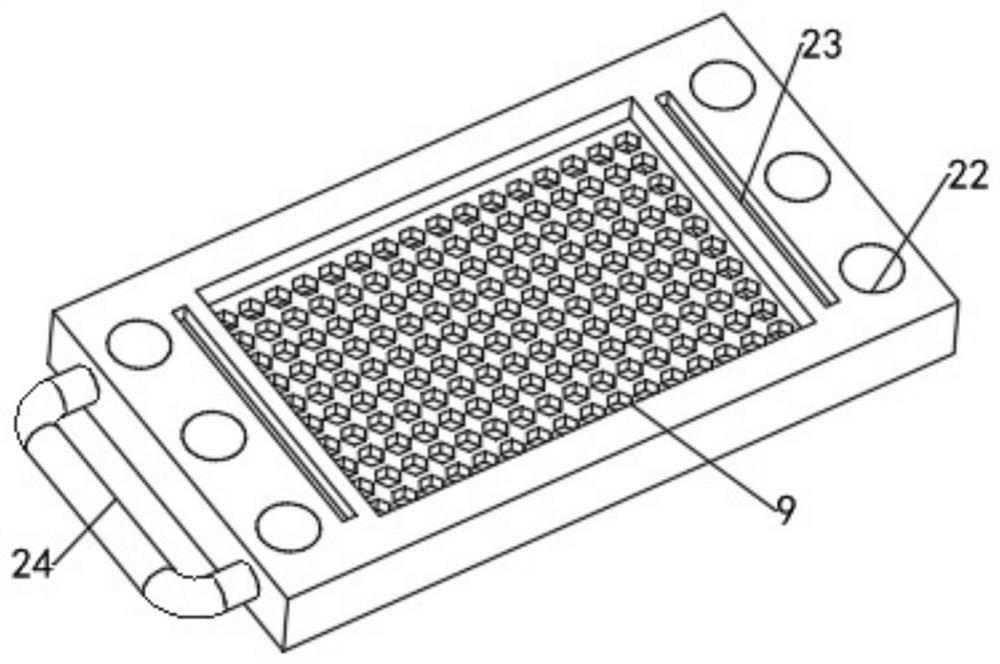

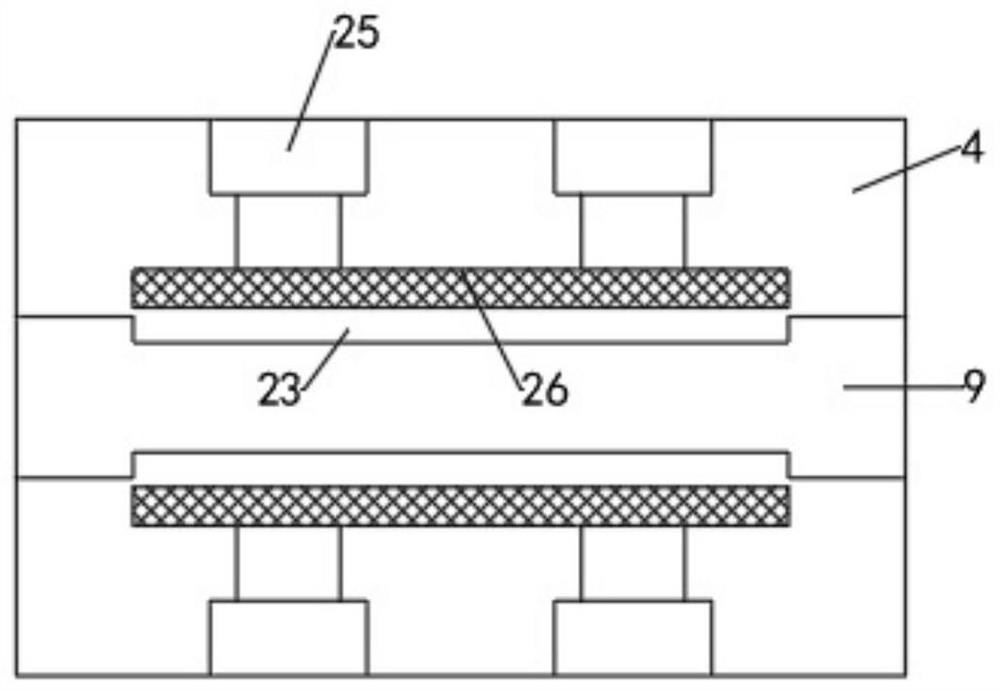

[0020] see Figure 1-4 , a rice screening device with a dust removal function, comprising a base plate 1, a sliding seat 2 is movably installed on the base plate 1, a screening chamber 4 is installed above the sliding seat 2, and a dust removal chamber 6 is connected to one side of the screening chamber 4; The upper end of the screening chamber 4 is provided with a feed hopper 5, and the inner side of the screening chamber 4 is equipped with a first screening net 9 and a second screening net 10 at intervals, and a plurality of assembly holes 22 are uniformly arranged on the first screening net 9. , the first screen 9 and the screen chamber 4 are assembled and connected by bolts, two non-penetrating positioning grooves 23 are arranged at intervals on the first screen 9, and the interior of the screen chamber 4 is slidably installed with a positioning block 26 via a lifting hydraulic cylinder 25, The positioning block 26 is matched with the positioning groove 23, and a side of t...

Embodiment 2

[0029] In order to improve the screening effect of the screening chamber 4, this embodiment is improved on the basis of Embodiment 1. The improvement is: two assembly seats 27 are arranged at intervals on the bottom plate 1, and the assembly seats 27 are respectively located on the sides of the sliding seat 2. Both sides, the both sides of slide seat 2 are fixedly connected with push rod 28, and cam 30 is installed in one of assembly seat 27, and cam 30 transmission is connected with motor, and return spring 29 is installed in the other assembly seat 27, and slide seat 2 two The side push rod 28 extends into the corresponding assembly seat 27 and is in contact with the cam 30 and the return spring 29 respectively. Under the action of the return spring 29, the push rod 28 is always in contact with the cam 30, thereby driving the The sliding seat 2 slides back and forth along the bottom plate 1 to promote the screening effect of rice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com