Laser cleaning method and device based on coaxial distance measurement and focal length real-time adjustment

A laser cleaning and laser technology, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as inability to overcome manual hand-held shaking, poor cleaning effect, complex surface structure of workpieces, etc., to save space and weight, improve Anti-interference ability and real-time adjustable focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to illustrate the technical solution of the present invention more clearly, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

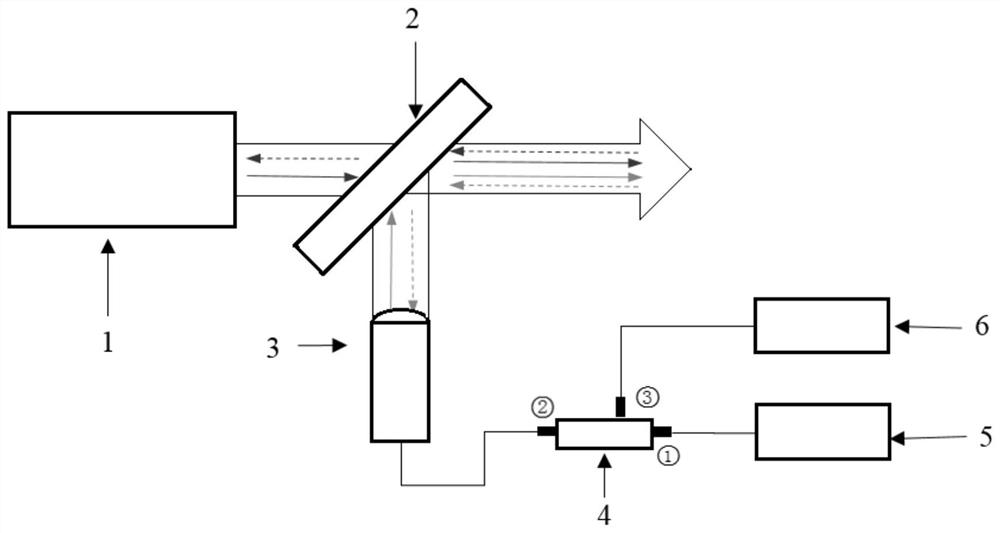

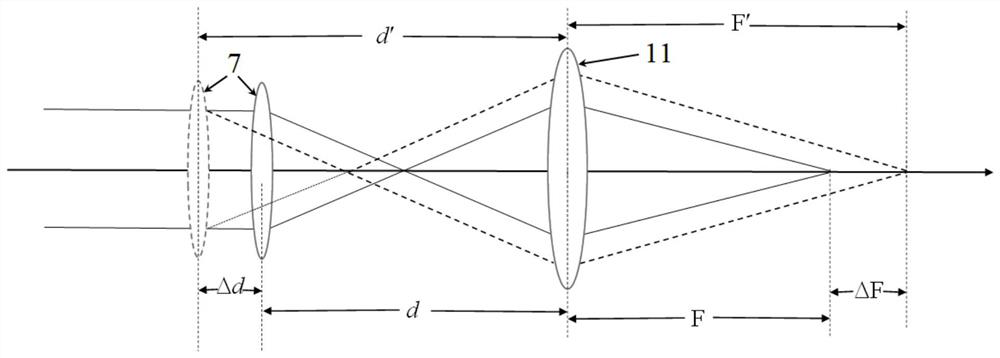

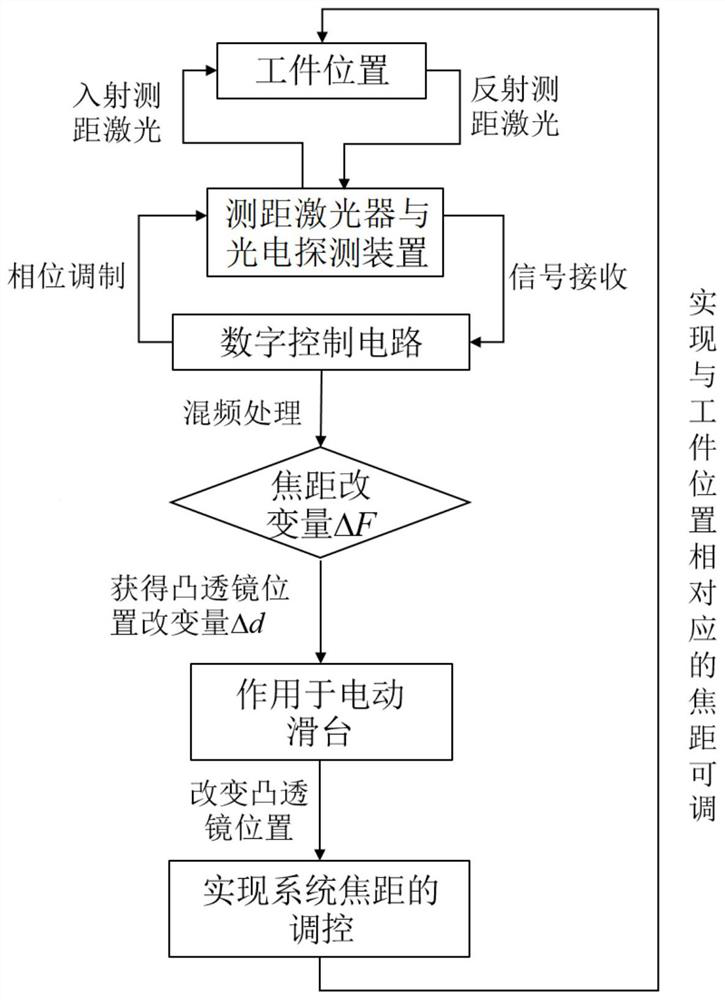

[0052] The present invention is mainly based on the coaxial range measurement and dynamic lens group, and uses the single dichroic light splitting flat plate 2 to realize the coaxial combination of the incident cleaning laser and the distance measurement laser and the separation of the reflected laser light, and obtain the distance information of the workpiece 12, Then through electronically controlled signal processing, the position of the convex lens 7 in the dynamic lens group is adjusted, and then the overall focal length of the lens group is changed, thereby realizing the automatic adjustment of the focal length of the system during the laser cleaning process and ensuring the power density acting on the workpiece 12 .

[0053] The technology mainly invol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com