Steel bar cutting device for constructional engineering construction

A technology for steel bar cutting and construction engineering, applied in cleaning methods and tools, smoke and dust removal, chemical instruments and methods, etc., can solve problems such as the inability to achieve automatic and stable equal-distance cutting of steel bars, and achieve soil agitation. The effect of improving governance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

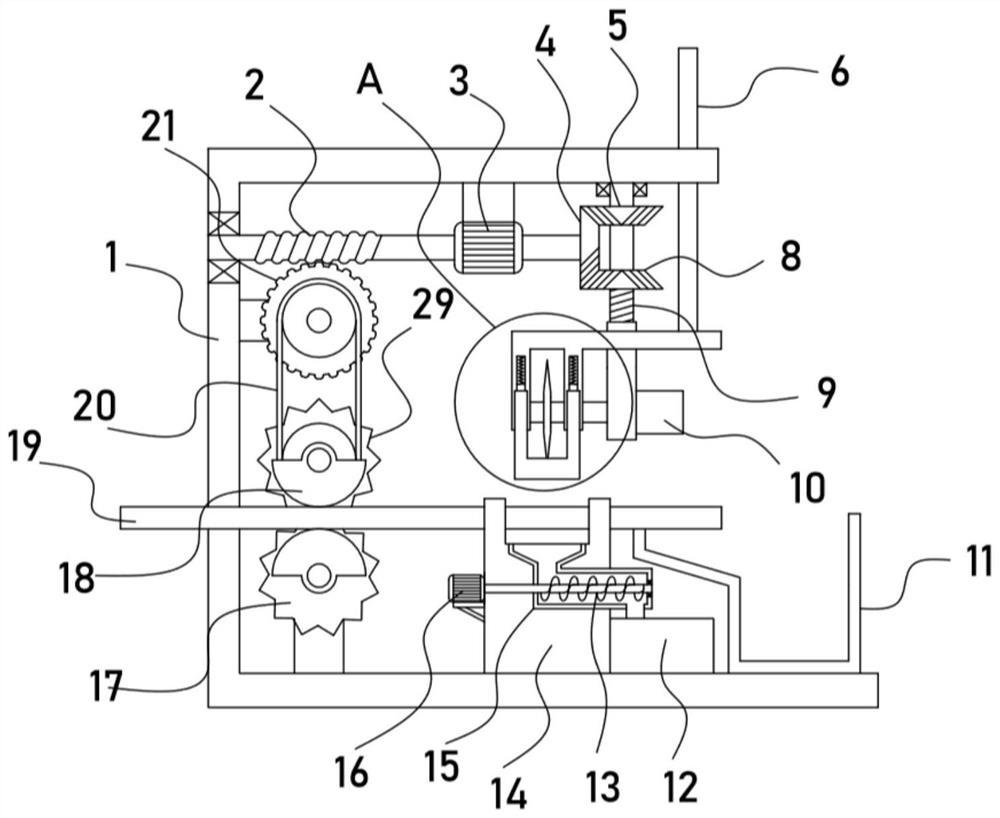

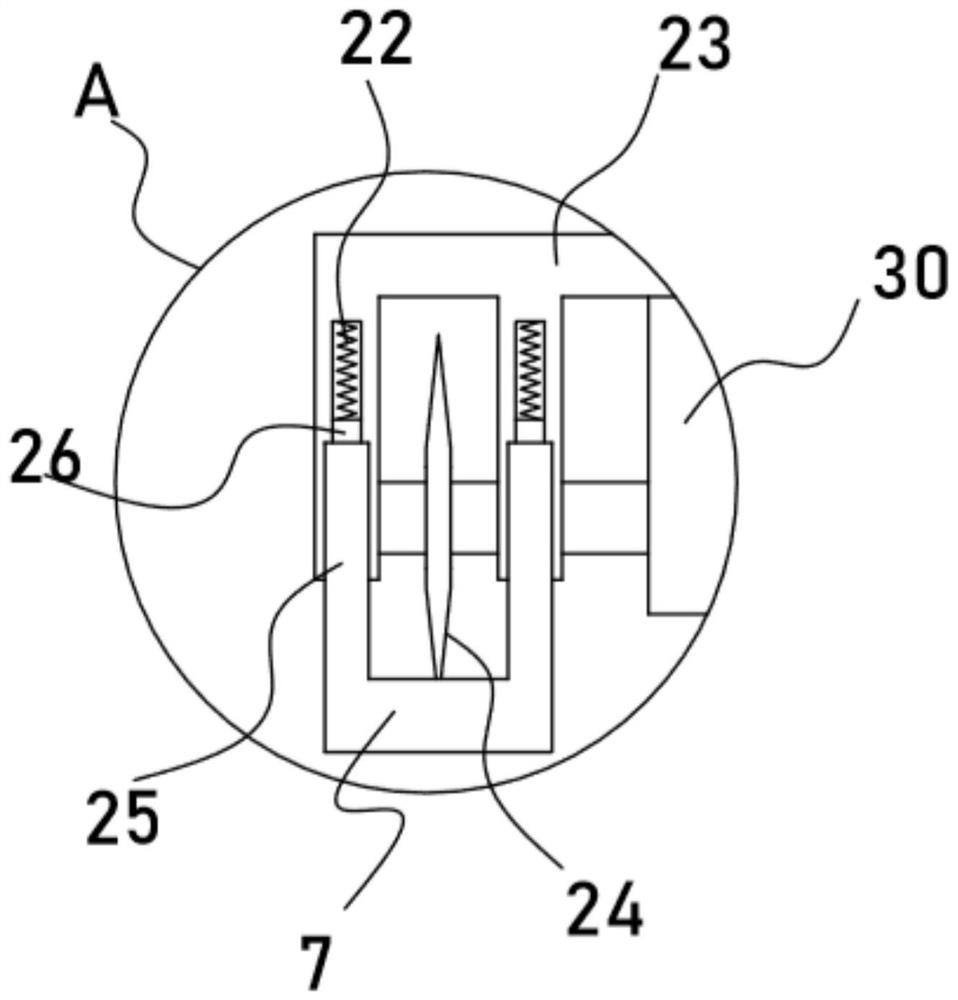

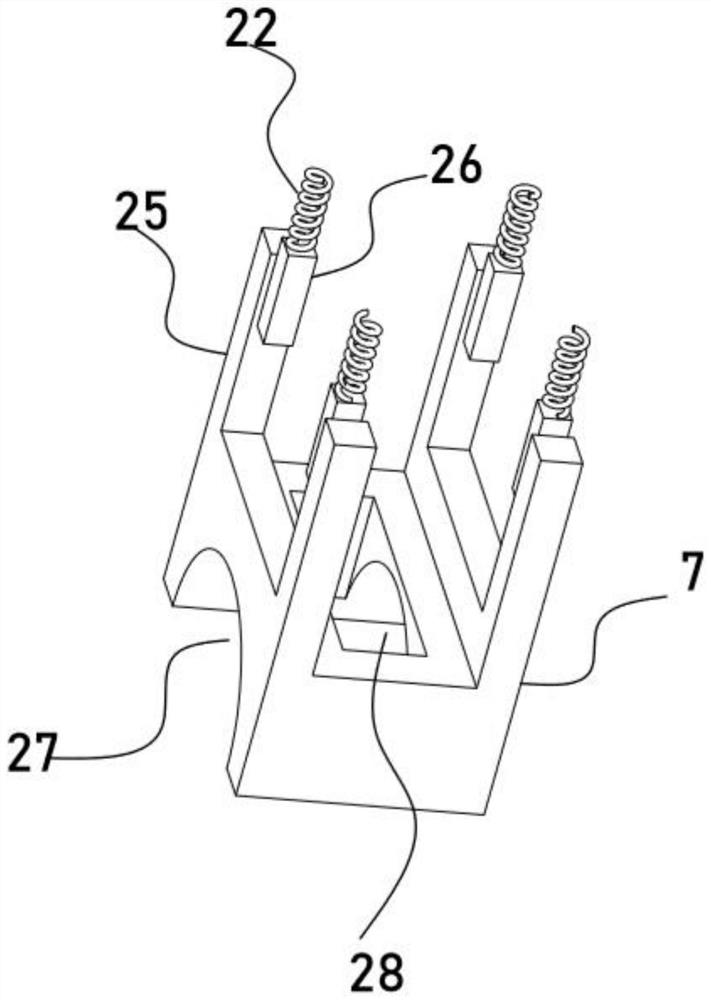

[0021] see Figure 1-3 , a kind of steel bar cutting device for building construction, comprising a fixed frame 1, a support frame 14 for supporting a steel bar 19 is fixed on the fixed frame 1, a biaxial motor 3 is fixed on the fixed frame 1, and one of the biaxial motors 3 The output shaft is driven and connected with a rotating mechanism, and the rotating mechanism is driven and connected with a translation mechanism for driving the lateral movement of the steel bar 19. The other output shaft of the biaxial motor 3 is driven and connected with a positive and negative mechanism. The mechanism drives and connects the limit frame 7, the limit frame 7 is fixed with a cutting motor 10, the output shaft of the cutting motor 10 is driven and connected with a cutting blade 24, the fixed frame 1 is fixed with a collecting box 12, and the collecting box 12 passes through the conveying mechanism It is connected with the support frame 14, and the right side of the support frame 14 is p...

Embodiment 2

[0026] On the basis of Embodiment 1, in addition, the reversing mechanism provided in this device includes the incomplete bevel gear 4 driven to rotate, and the incomplete bevel gear 4 is alternately meshed with coaxially fixed bevel gear 15 and bevel gear II8. The lifting mechanism includes a threaded rod 9 coaxially fixed with the bevel gear II8, a threaded sleeve 30 is threaded on the threaded rod 9, and a lifting frame 23 is fixedly installed on the threaded sleeve 30 .

[0027] The double-axis motor 3 drives the worm 2 to rotate while driving the incomplete bevel gear 4 to rotate. During the rotation of the incomplete bevel gear 4, the incomplete bevel gear 4 alternately meshes with the bevel gear I5 and the bevel gear II8, thereby realizing the alternate clockwise rotation of the threaded rod 9 At this time, the threaded sleeve 30 drives the lifting frame 23 to reciprocate vertically, so that the rotating cutting blade 24 can cut the reinforcing bar 19 . The incomplete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com