Novel casting system of die-casting die for large 5G communication radiator part

A die-casting mold and casting system technology, which is applied in the field of new casting systems, can solve the problems of cooling fins and other problems, and achieve the effects of stable flow filling, prolonging service life, and reducing the defective rate of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

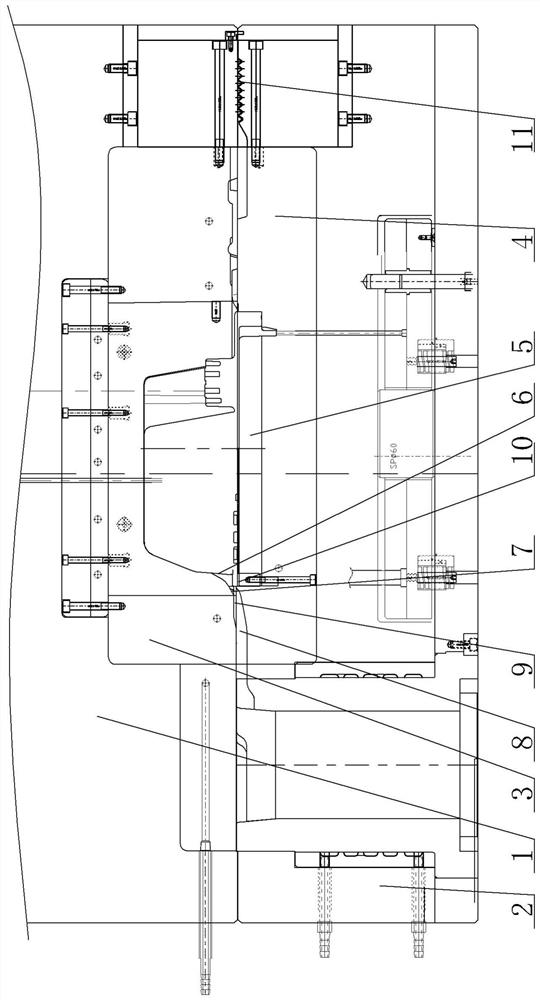

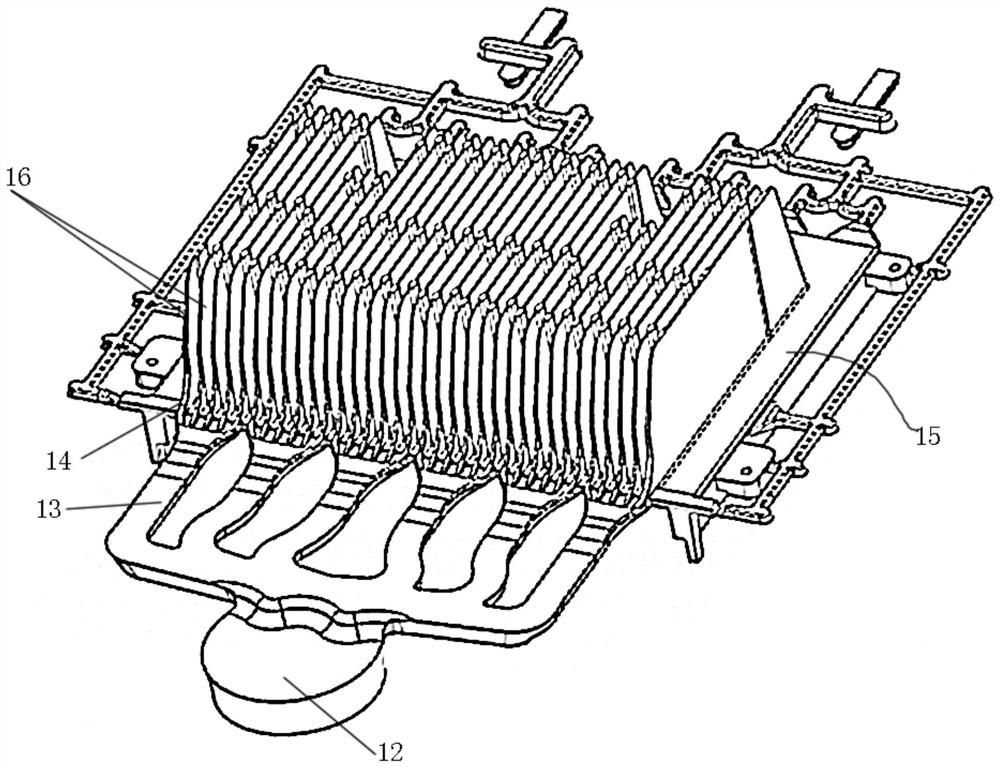

[0013] A new casting system for die-casting molds for large 5G communication radiator parts, see figure 1 , figure 2 : It includes a movable mold part 1 and a fixed mold part 2, the central area of the movable mold part 1 towards the fixed mold part 2 is provided with a movable mold core 3, and the central area of the fixed mold part 2 towards the movable mold core 3 is provided with a fixed mold The core 4, the movable mold core 3 and the fixed mold core 4 are combined to form a cavity 5, and the inlet position of the cavity 5 is arranged with a number of fin cavity areas 6, and each fin cavity area 6 faces the feeding A diversion rib cavity area 7 is provided at the corresponding position of the mouth, and the diversion rib cavity area 7 is a circular arc diversion structure that gradually expands from the feed inlet to the designed end surface of the fin.

[0014] Between the movable mold core 3 and the fixed mold core 4, there are also a main channel inlet 8 and a ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com