An experimental rock sample device for multi-angle drilling anisotropic media

An anisotropic, multi-angle technology, applied in the field of multi-angle drilling anisotropic medium experimental rock sample device, can solve the problems of insufficient clamping, pollution of the working environment, single sampling angle, etc., to achieve convenient operation and good working environment Clean and tidy, the effect of tidy working interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

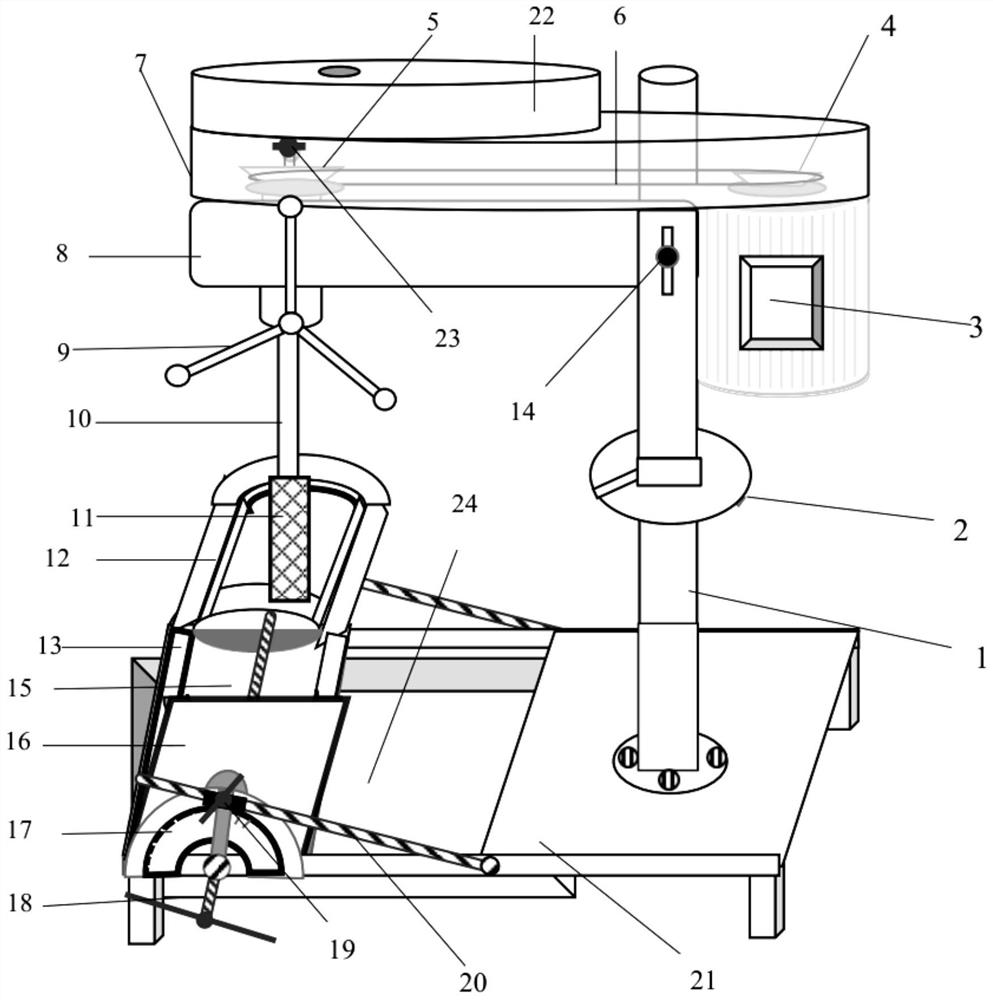

[0047] A drilling rig screw column 1 is vertically arranged on the drilling rig base 21 , a drilling rig lifting carousel 2 is arranged in the middle of the drilling rig screw column 1 , a sampler motor 3 is arranged on the top side of the drilling rig screw column 1 , and a top protective shell 7 is arranged on the top of the drilling rig screw column 1 . . The top protective shell 7 has a driving pulley 4 and a driven pulley 5 , and the driving pulley 4 and the driven pulley 5 are connected and driven by a power transmission V-belt 6 . The lower part of the driven pulley 5 is provided with a drilling rig beam 8 , and the other end of the drilling rig beam 8 is fixed to the top of the drilling rig screw column 1 through the drilling rig azimuth adjustment knob 14 . The lower end of the drill beam 8 is provided with a drill bit power transmission shaft 10, the drill bit power transmission shaft 10 is provided with a drill bit lifting and rotating handle 9, and the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com