Container blowing method

A container and bottle body technology, applied in the field of container blowing, can solve problems such as high cost and increase pollution risk, and achieve the effects of low cost, avoiding pollution risk and saving equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

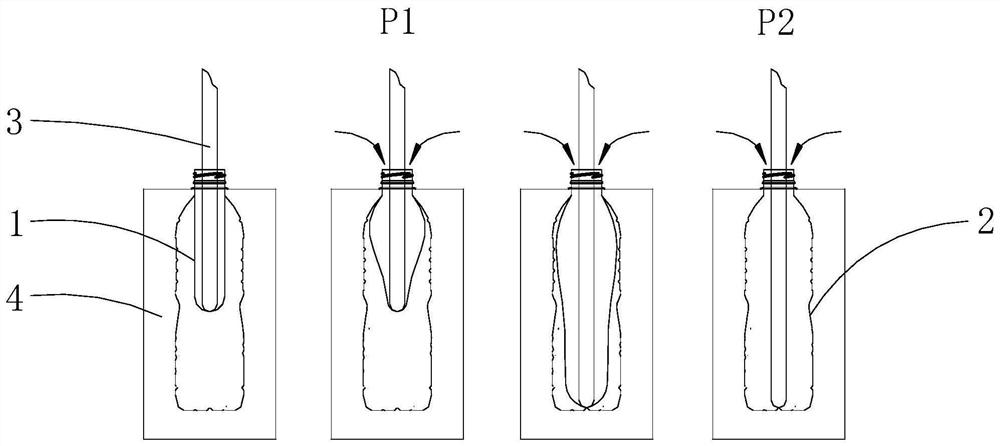

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] see figure 1 Shown, above-mentioned a kind of container blowing method is used for blowing the preform 1 of PET material, comprises the following steps:

[0021] Under sterile conditions:

[0022] (1) In the P1 stage, put the preform 1 into the mold 4, extend the stretching rod 3 from the mouth of the preform 1 to the bottom of the preform, the stretching rod 3 stretches the preform 1, and at the same time, the low-pressure air Pass in the bottle base 1, the bottle base 1 is pre-blown, the stretch rod 3 carries out axial expansion to the bottle base 1, and the low-pressure gas carries out the radial expansion to the bottle base 1; In the present embodiment, the low-pressure gas is gaseous acetylene.

[0023] (2) In the P2 stage, the high-pressure gas is passed into the preform 1, and the preform 1 is completely pressed against the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com