Auxiliary mounting equipment for road and bridge embedded parts

A technology for installation equipment and embedded parts, which is applied in the field of auxiliary installation equipment, and can solve the problems of wasting time, inability to realize simultaneous insertion and fixation of multiple ground nails, and insufficient fast adjustment of the clamping device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

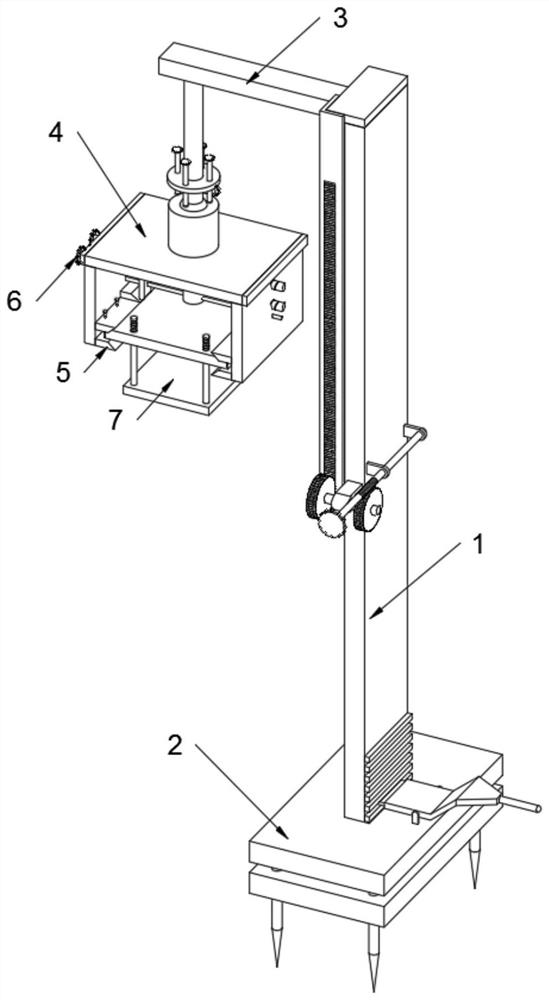

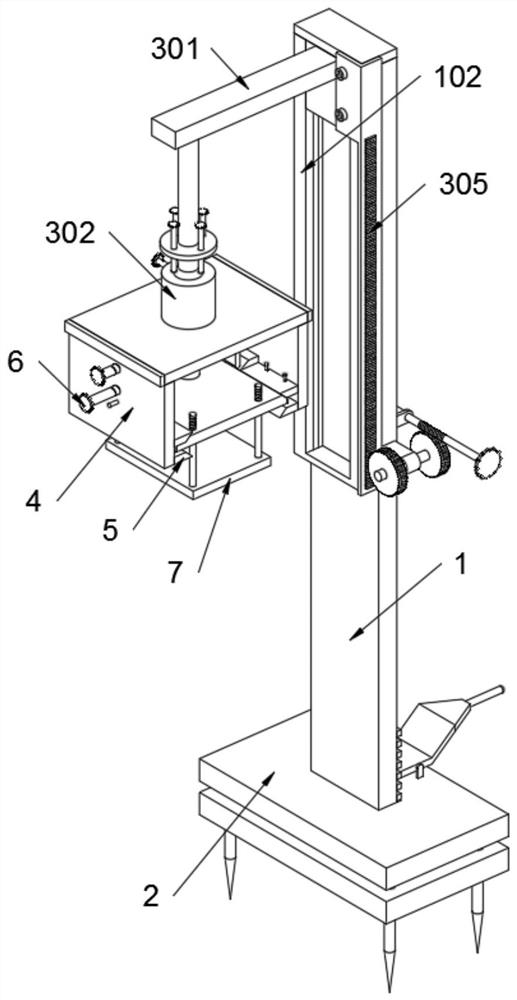

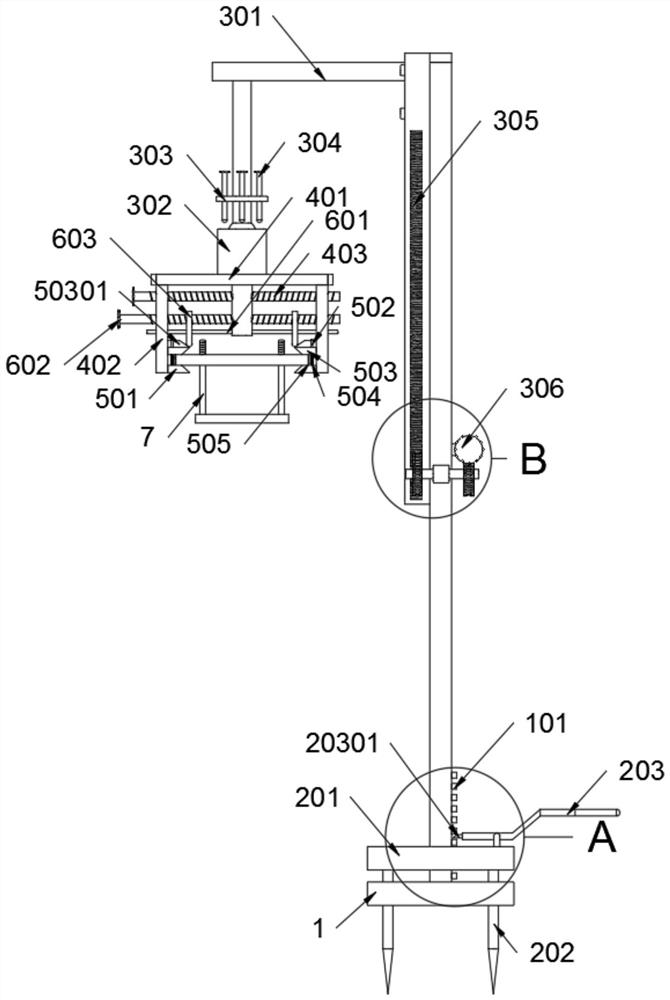

[0036] as attached figure 1 to attach Figure 8 Shown:

[0037] The invention provides an auxiliary installation device for embedded parts of roads and bridges, which includes a base 1; a fixing seat 2 is plugged into the base 1, and a mounting arm structure 3 is slidably connected to the base 1, and the mounting arm structure 3 is The clamping structure 4 is fixedly connected by bolts; refer to e.g. image 3 and Figure 4 , the fixed seat 2 includes a handle 203 and an elastic bayonet 20301, the handle 203 is rotatably connected to the main body plate 201, and an elastic bayonet 20301 is installed on the head end of the handle 203; Moreover, the head end of the elastic detent 20301 has an inclined structure, and when the handle 203 is pressed back and forth, the fixing base 2 is in a state of upward movement, thereby realizing the rapid extraction of the ground nail 202; refer to Figure 6 , the mounting arm structure 3 includes an annular plate 303 and a limit bolt 304, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com