Textile machine with air flow conveyor and filter device

A filtering device and air conveying technology, applied in the textile field, can solve the problems affecting the integrity of the fabric and the defects of the textile fabric, and achieve the effect of reducing the defects and improving the integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] as attached figure 1 to attach Figure 4 Shown:

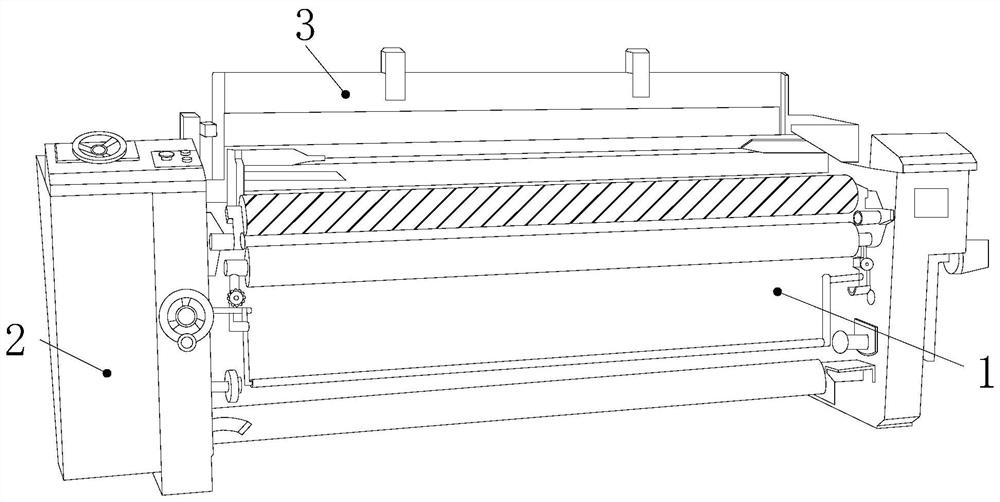

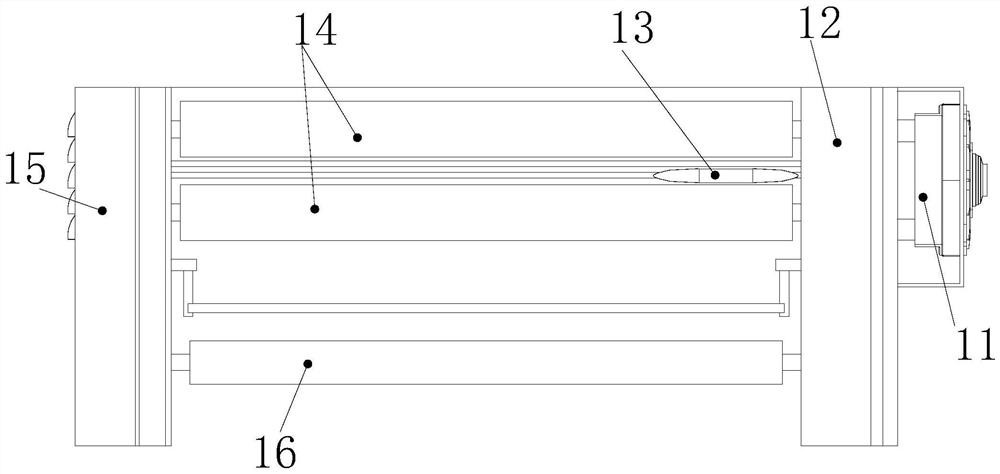

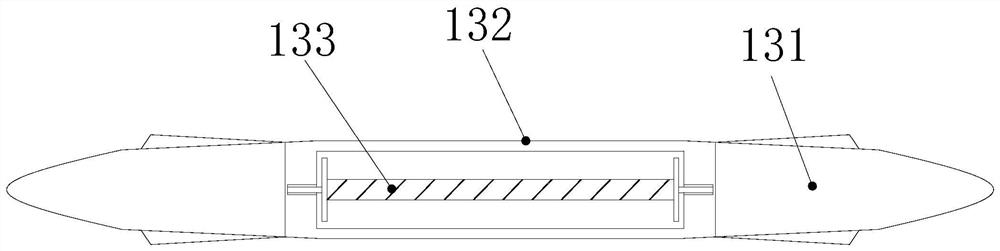

[0025] The invention provides a textile machine with an airflow conveyor and a filter device, the structure of which comprises a textile rack 1, a cover 2, and a thread frame 3, the outer side of the left end of the textile frame 1 is riveted to the outer cover 2, and the thread frame 3 is connected to the outer cover 2 by riveting. The upper side of the textile frame 1 is embedded and connected. The textile frame 1 includes a fan 11, a transmission box 12, a spindle 13, a distribution roller 14, a filter box 15, and a collection roller 16. The fan 11 is welded to the right side of the transmission box 12. The transmission box 12 is axially connected to the right side of the distribution roller 14, the spindle 13 is movably engaged between the transmission box 12 and the filter box 15, the filter box 15 is axially connected to the left side of the distribution roller 14, and the collection roller 16 is connected betwee...

Embodiment 2

[0031] as attached Figure 5 to attach Figure 7 Shown:

[0032] Wherein, the cutting head 31b includes an arc-shaped plate b1, a fixed block b2, a dust shield b3, a spring plate b4, and a cutting wall b5. The arc-shaped plate b1 is attached to the lower side of the cutting wall b5, and the fixed block b2 is welded to the upper right side of the arc-shaped plate b1, the dust shield b3 is welded to the upper right side of the fixed block b2, and the elastic plate b4 is connected between the inner side of the middle part of the dust shield b3 and the left end of the fixed block b2 , the left end of the cutting wall b5 is axially connected to the left end of the conical cover 31a, and the spring plate b4 is made of carbon spring steel, which has the characteristics of good elasticity and fatigue resistance, so that the dust shield b3 can reset itself, and there is It is beneficial to reduce the clogging of the cutting head 31b by floating flocs caused by thin wires.

[0033] W...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap