Reciprocating compressor packing sealing mechanism

A technology for packing seals and compressors, which is applied in engine seals, machines/engines, liquid variable displacement machines, etc. It can solve the problems of long packing components, inconvenient installation and maintenance, and high maintenance costs, so as to reduce the heat of work friction , Increase the service life and improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

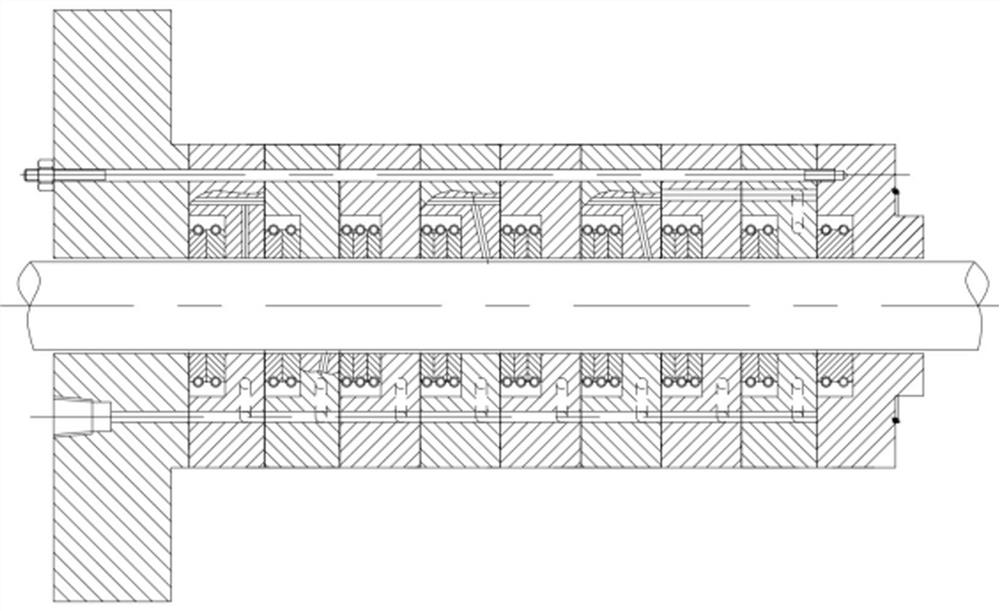

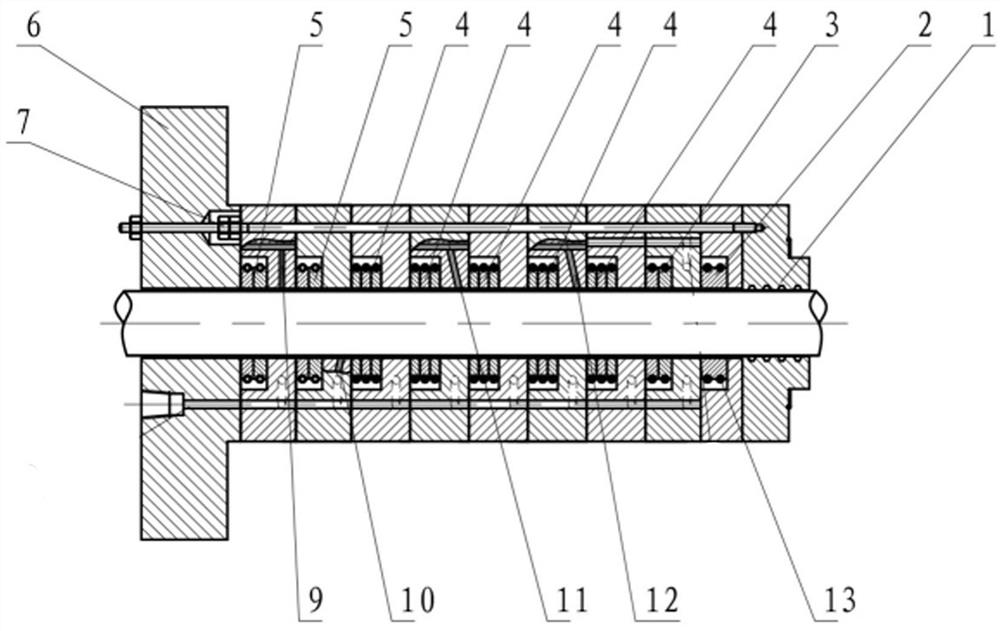

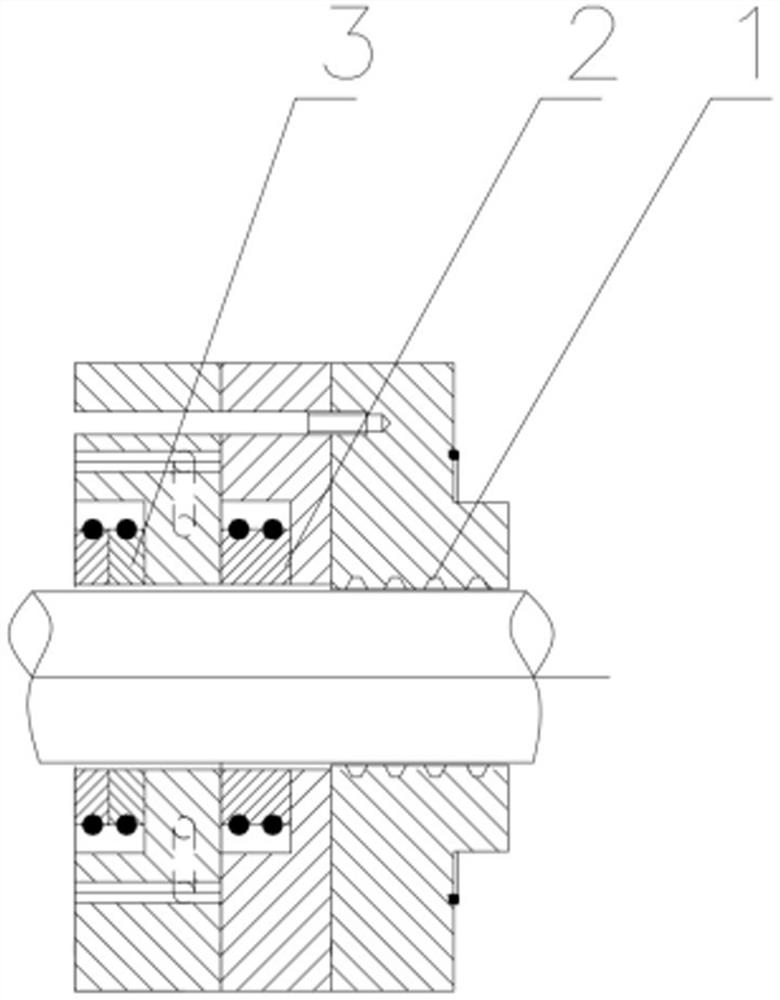

[0017] Such as figure 2 and 3 As shown, a packing seal mechanism of a reciprocating compressor includes a plurality of packing seal rings 4, leakage air seal rings 5, first decompression ring 2, second decompression ring 3 and metal spring ring 13, and the first Decompression ring 2. Between the front piston rod of the decompression ring and the box body, there are several annular sealing ring grooves 1 arranged in sequence. A series of shut-off gaps and expansion cavities are formed between the ring grooves. The sealed medium passes through the tortuous labyrinth. Throttle effect occurs when there is a gap between the labyrinth ring grooves 1, the high-pressure gas in the compressor cylinder is firstly decompressed at the labyrinth ring groove to reduce the impact of the high-pressure gas in the cylinder, and then passes through the first The decompression ring 2 and the second decompression ring 3 carry out two-stage and three-stage decompression, and the combined decompre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com