Unified valve assembly for ventilating a die casting mold

A die-casting mold and assembly technology, which is applied in the field of unified structure valve assembly for die-casting mold ventilation, can solve the problems of complex mechanism, inability to interact smoothly, complex structure, etc., and achieve the effect of prolonging the ventilation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. When describing the embodiments of the present invention in detail, details that are not directly related to the technical features of the present invention or that can be easily understood by those skilled in the art to which the present invention belongs will be omitted in detailed description.

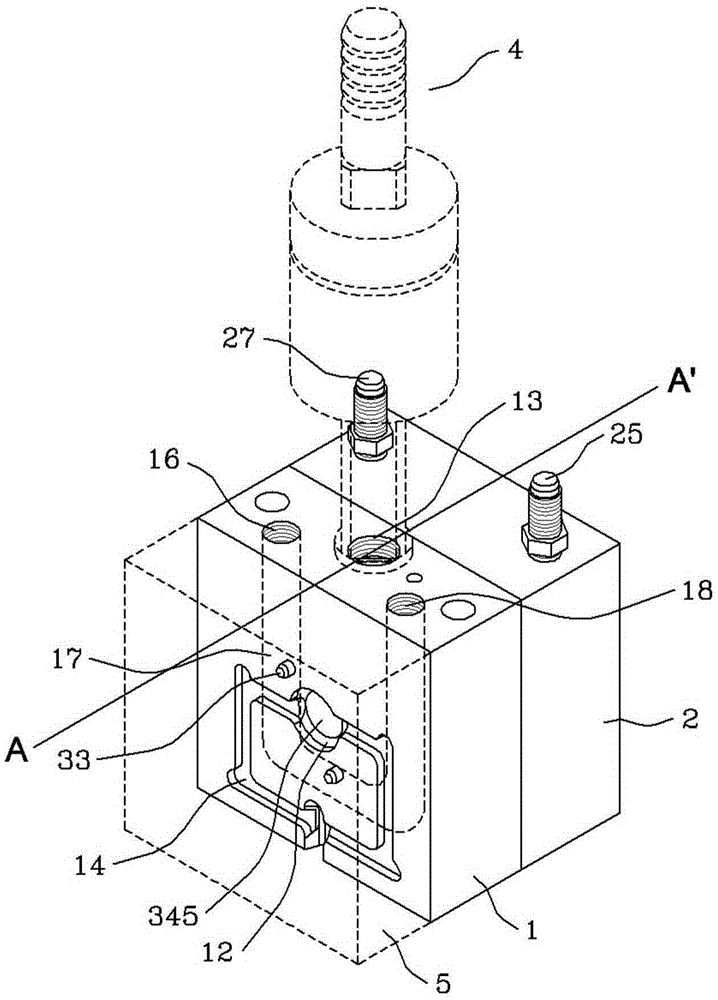

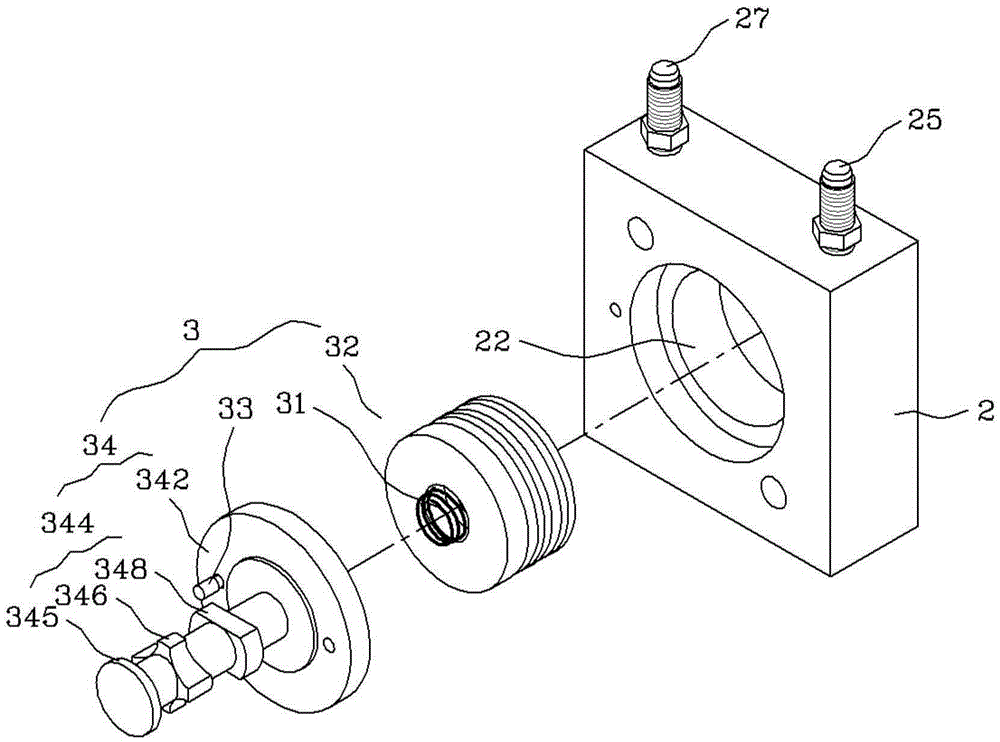

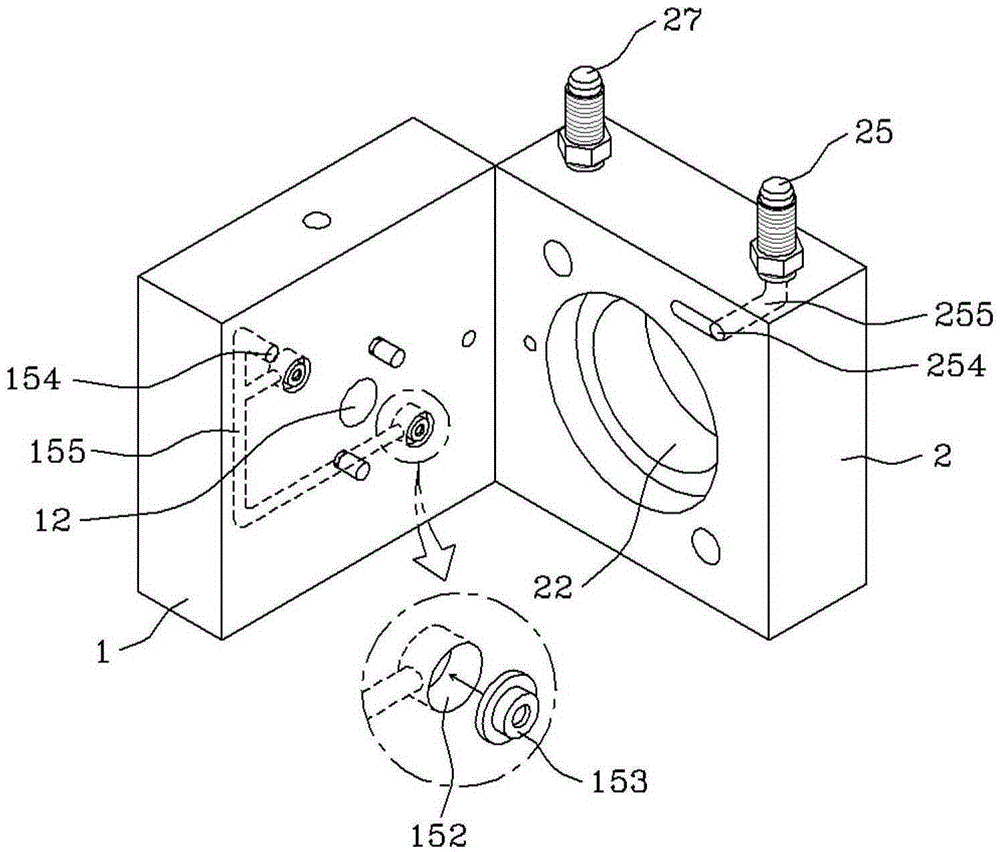

[0037] figure 1 is a schematic overall structure diagram of a unified valve assembly for die-casting mold ventilation according to the present invention, Figure 5 yes figure 1 The schematic cross-sectional structure diagram of line A-A' is shown. As shown in the figure, the present invention discloses a valve assembly including a casted mass block 1 , a pressurized block 2 and a movable block 3 . These constituent elements are described in detail below.

[0038] The cast mass 1 is a portion into which molten metal to be cast (hereinafter refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com