Cleaning device for non-decomposable one-way valve of airplane and cleaning method of cleaning device

A technology of one-way valve and cleaning device, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, valve devices, etc., which can solve problems such as ineffective removal, poor valve reset, and inability to disassemble and clean, so as to avoid product scrapping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

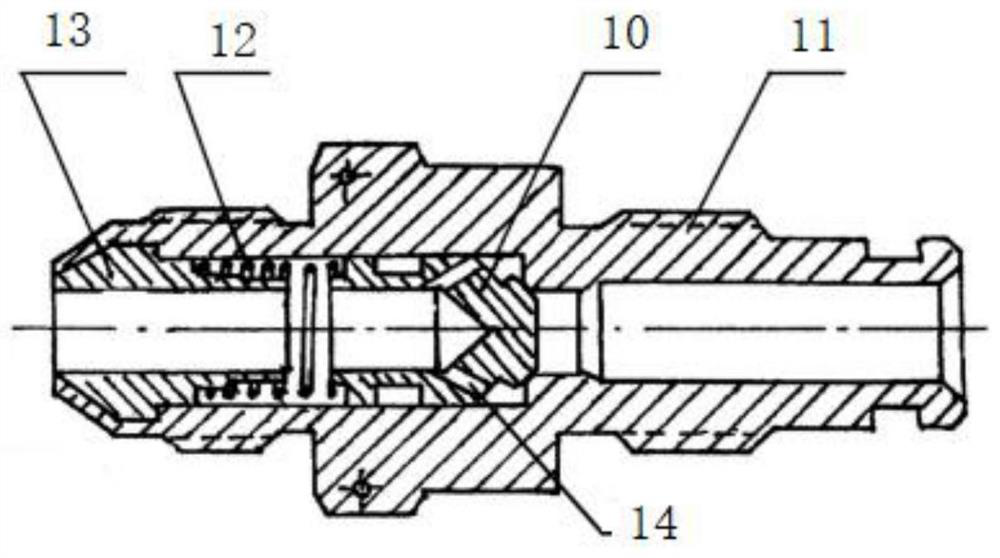

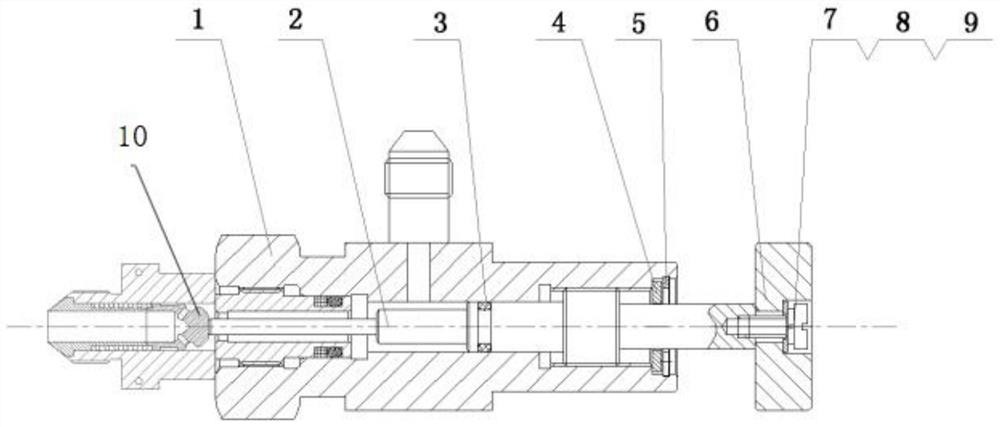

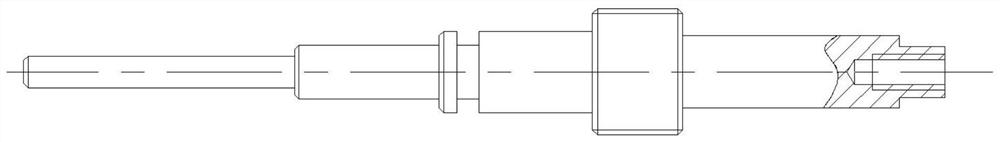

[0020] Such as Figure 1 to Figure 4 As shown, a non-decomposable one-way valve cleaning device for aircraft includes an adapter 1 that is mated with the end face profile of the one-way valve 10, and a device that is arranged in the adapter 1 to push back the one-way valve 10 for reverse pressurization and flushing. The mandrel 2, the handle 6 that is arranged on the end of the mandrel 2 to facilitate force application.

[0021] By using the mandrel 2 to push the one-way valve 10, reverse pressure flushing is realized, and the inside of the valve is guaranteed to be effectively cleaned. After grinding, the grinding residue can be effectively cleaned and removed, and the valve and the shell 13 of the non-decomposable one-way valve 10 are solved. The problem of cleaning the remaining rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com