X-ray residual stress testing method of Ti2AlNb alloy for casing

A technology of residual stress and testing method, applied in the direction of force/torque/work measuring instrument, measuring force, measuring device, etc., can solve the problems of unusable parts, damaged parts, etc., and achieve the effect of solving inaccurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

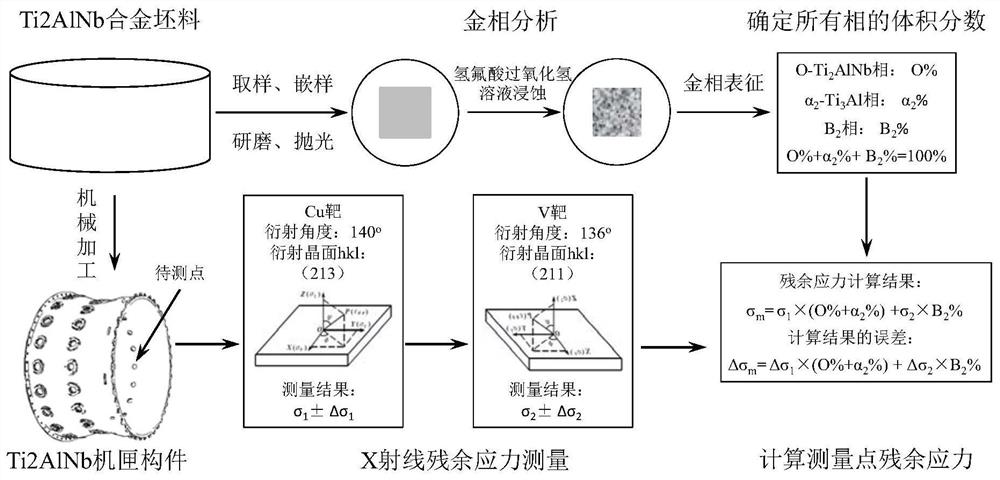

[0066] A Ti2AlNb alloy casing component used in an aero-engine has a nominal material composition of Ti-11Al-38Nb-2Mo-1.5Zr, and it is required to measure the surface residual stress after machining.

[0067] In order to detect the residual stress at a measurement point of the Ti2AlNb alloy casing component, after the machining is completed, the following steps are carried out:

[0068] Determine the original blank corresponding to the Ti2AlNb alloy casing component to be tested for residual stress, and prepare a Ti2AlNb metallographic sample from the original blank;

[0069] Embedding, grinding and polishing of Ti2AlNb metallographic samples;

[0070] Wipe and etch Ti2AlNb metallographic samples with hydrofluoric acid hydrogen peroxide solution;

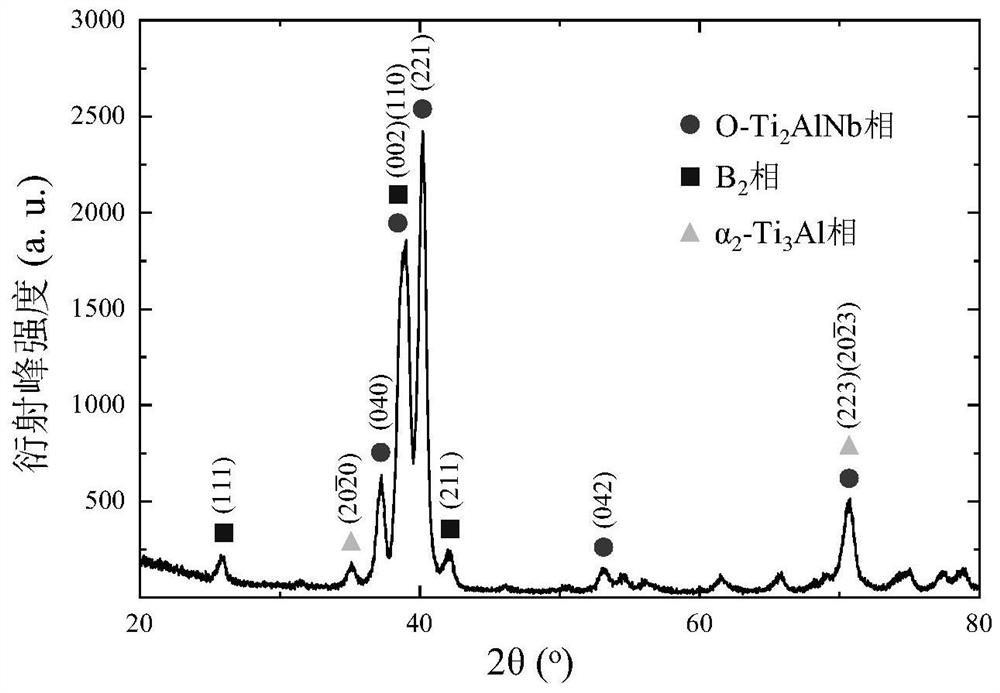

[0071] Determination of O-Ti in metallographic samples by metallographic analysis 2 AlNb phase volume fraction value is 22%, α 2 -Ti 3 Al phase volume fraction value is 7% and B 2 The value of phase volume fraction is 71%, sati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com