Residue cleaning and defective product screening device for hexagonal nut production

A screening device and hexagonal technology, which is applied in the field of parts processing, can solve the problems of inconvenient and quick removal and collection, and defective products are easy to get stuck in the sieve holes, so as to prevent stuck, avoid stuck phenomenon, and reduce stuck The effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

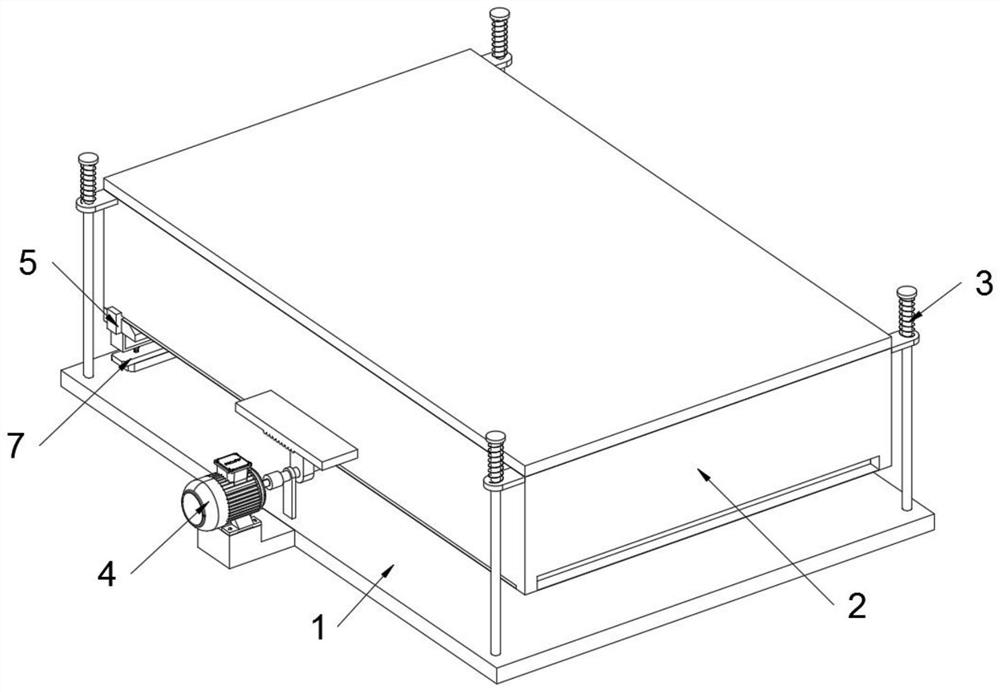

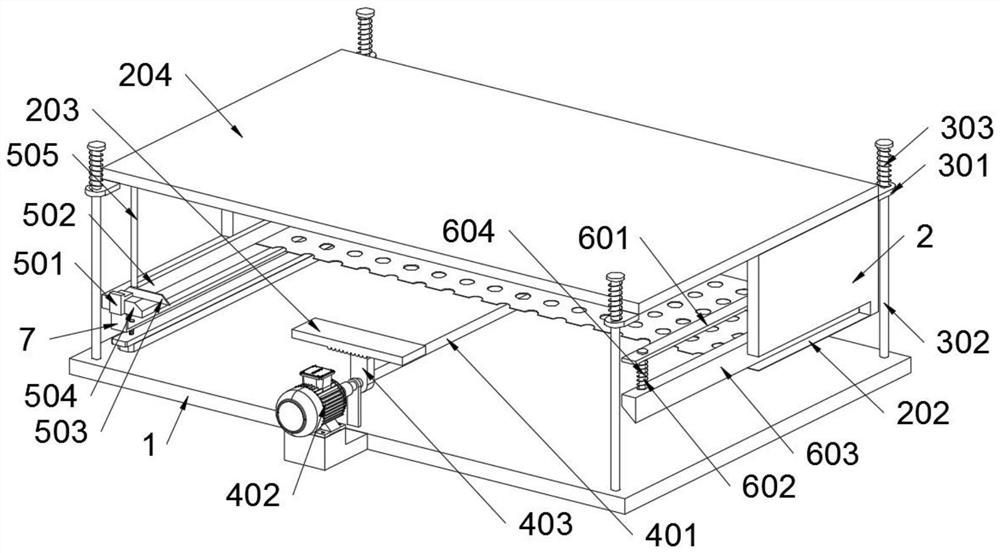

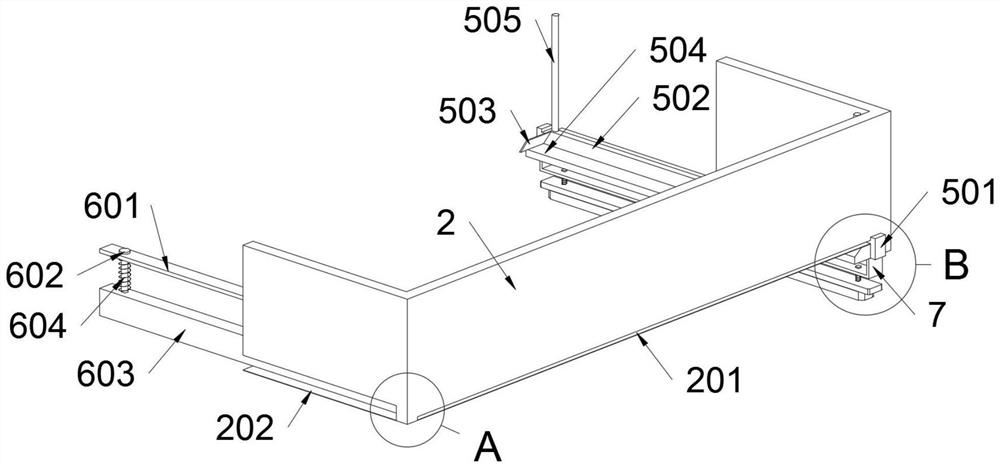

[0035] as attached figure 1 To attach Figure 9 Shown:

[0036] The invention provides a residue cleaning and defective product screening device for the production of hexagonal nuts, including a main body seat 1 and a force-bearing block 203; Box 2; a cleaning structure 5 is slidingly connected to the screening box 2, and a shielding structure 6 is installed in the screening box 2, and a cleaning structure 7 is installed on the cleaning structure 5; a driving structure 4 is installed on the main body seat 1; refer to Such as figure 2 , the force-bearing block 203 includes protrusions 20301, and the bottom surface of each force-bearing block 203 is welded with protrusions 20301 in a rectangular array, and the protrusions 20301 are in contact with the toggle block A403, and when the toggle block A403 rotates with the rotating shaft 401 When the force block 203 and the screening box 2 are in a reciprocating state up and down, they are also in a small vibration state, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com