Equipment for making and slitting cold rice noodles

A technology of cutting strips and equipment, applied in metal processing and other directions, can solve the problems of insufficient uniformity of Liangpi, affecting the appearance of food, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

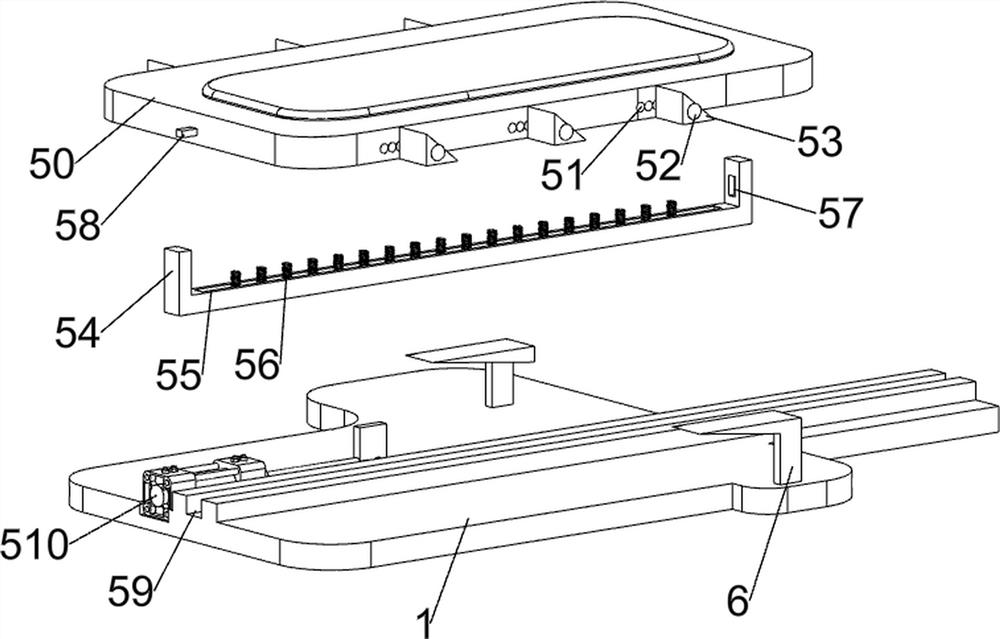

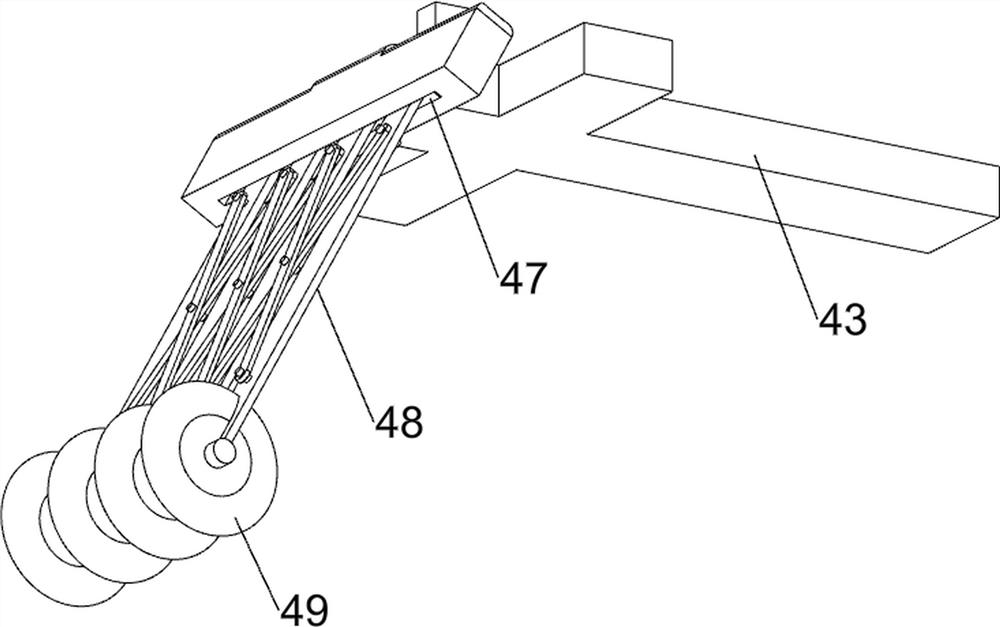

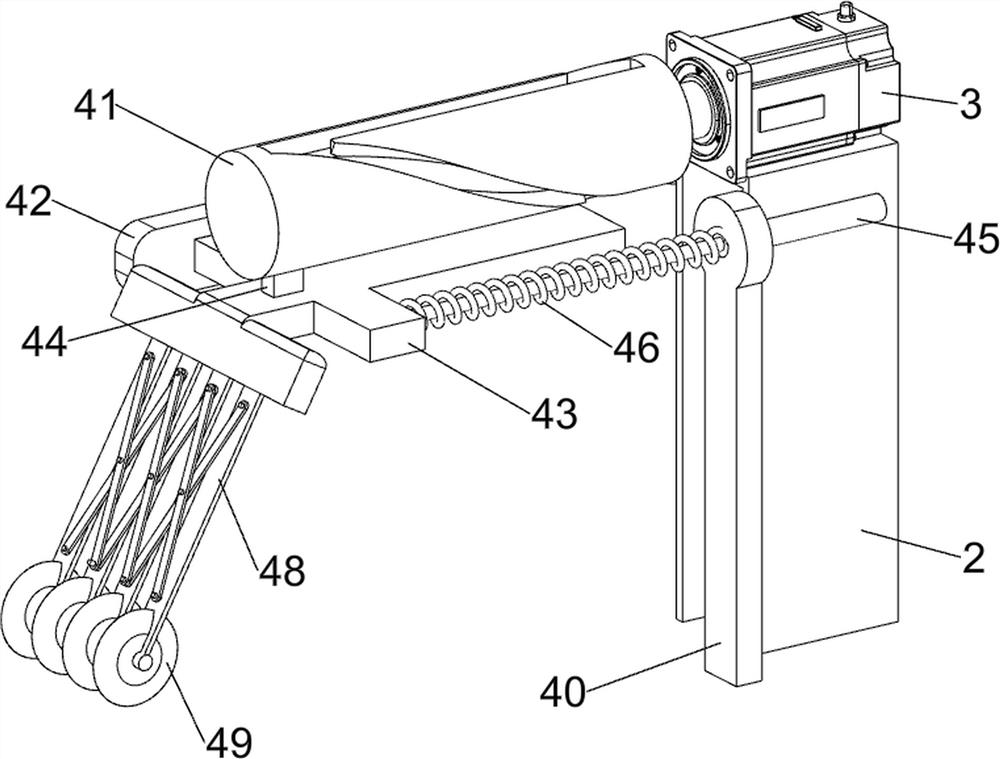

[0022] An apparatus for cutting Cold production, such as Figure 1-5 Shown, comprises a base 1, a first support frame 2, the servo motor 3, the cutting means 4, 5 and the second pusher mechanism wedge block 6, the upper portion of the front side of the base 1 is connected by way of a fixed support frame is provided with a first 2, the upper portion of the first support frame 2 is provided with the servo motor 3, the upper portion of the front side of the base 1 is provided with a cutting mechanism 4 for cutting Cold cutting mechanism 4, the output shaft of the servo motor 3 is connected to the cutting mechanism 4, the base 1 means provided on the upper pusher 5, the upper portion of the base 1 is provided with a second longitudinal symmetrical wedge block 6.

[0023] When the user needs to cut Cold, the present device may be used, it will produce a good Liangpi first placed on the pusher mechanism 5, and then opens the servo motor 3, the servo motor 3 to drive the cutting mechanism...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap