Toothbrush box processing system

A processing system and toothbrush box technology, applied in box production operations, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as low production efficiency, achieve high production efficiency, low error, and reduce manual utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

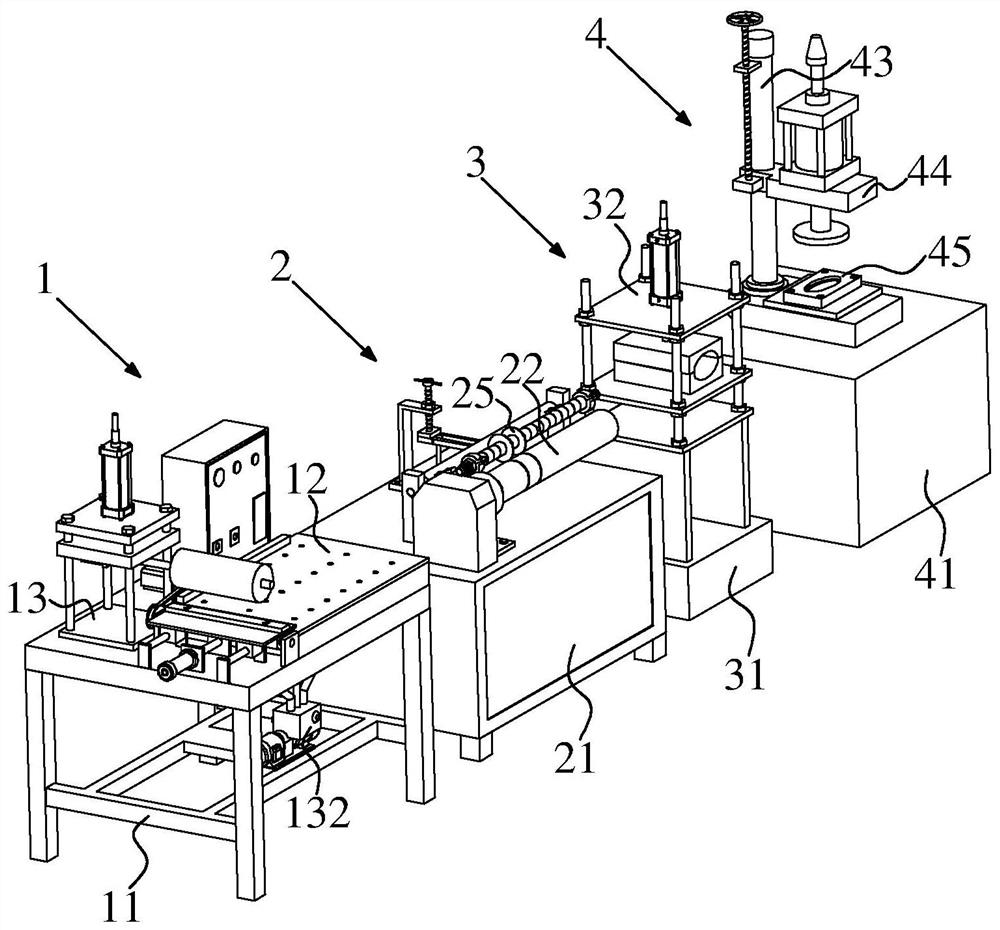

[0050] The following is attached Figure 1-15 The application is described in further detail.

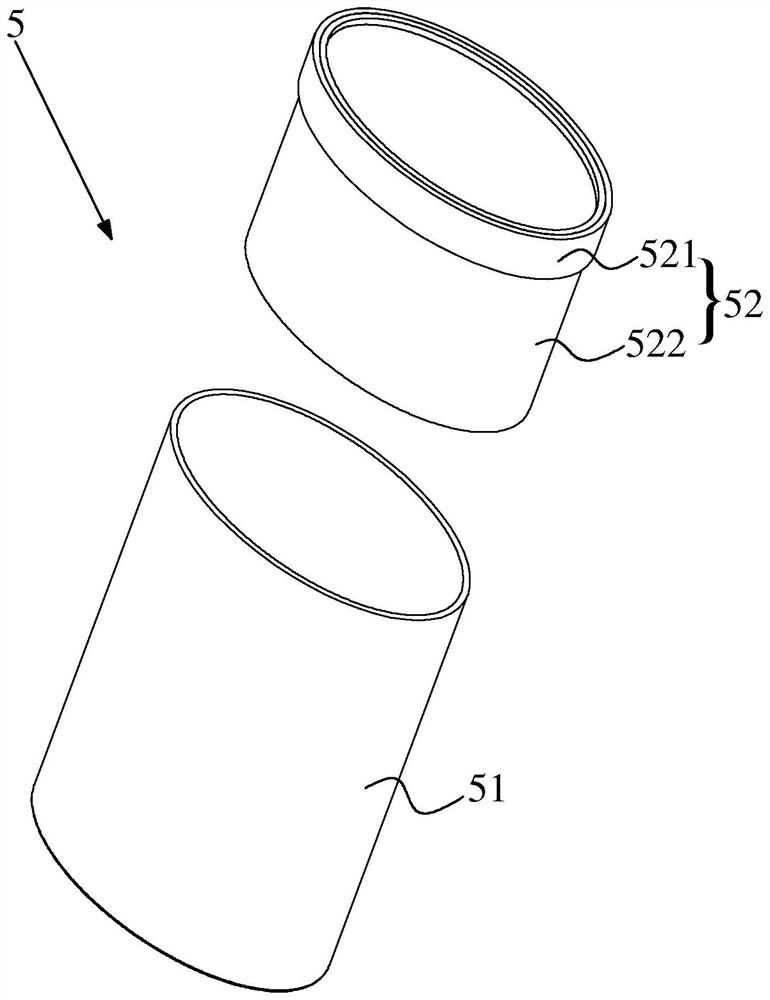

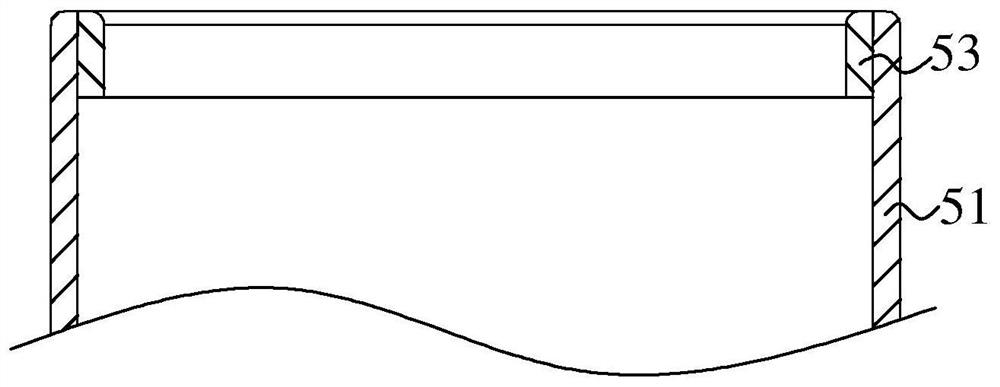

[0051] refer to figure 1 and figure 2 , the toothbrush box 5 includes a cylinder 51 and a cover 52, the cover 52 is fastened on the mouth of the cylinder 51, the cross-section of the cylinder 51 and the cover 52 is oval, and the outer wall of the cylinder 51 and the cover 52 Both are provided with wrapping paper; the cover body 52 includes an abutting portion 521 and a tightening portion 522, and the aperture size of the abutting portion 521 is the same as that of the cylinder body 51; the aperture size of the tightening portion 522 is smaller than that of the abutting portion 521 The size of the aperture, one end of the tensioning part 522 is snap-fitted in the abutment part 521 and fixed with the abutment part 521 by glue, and the other end is snap-fitted in the barrel 51. Since the stretching part 522 is a paper tube elastic material, so that the cover 52 is fastened to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com