Elevator maintenance system

An elevator maintenance and elevator technology, applied in the elevator field, can solve the problems of poor coordination, high cost, unskilled business, etc., and achieve the effect of enhanced protection function and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

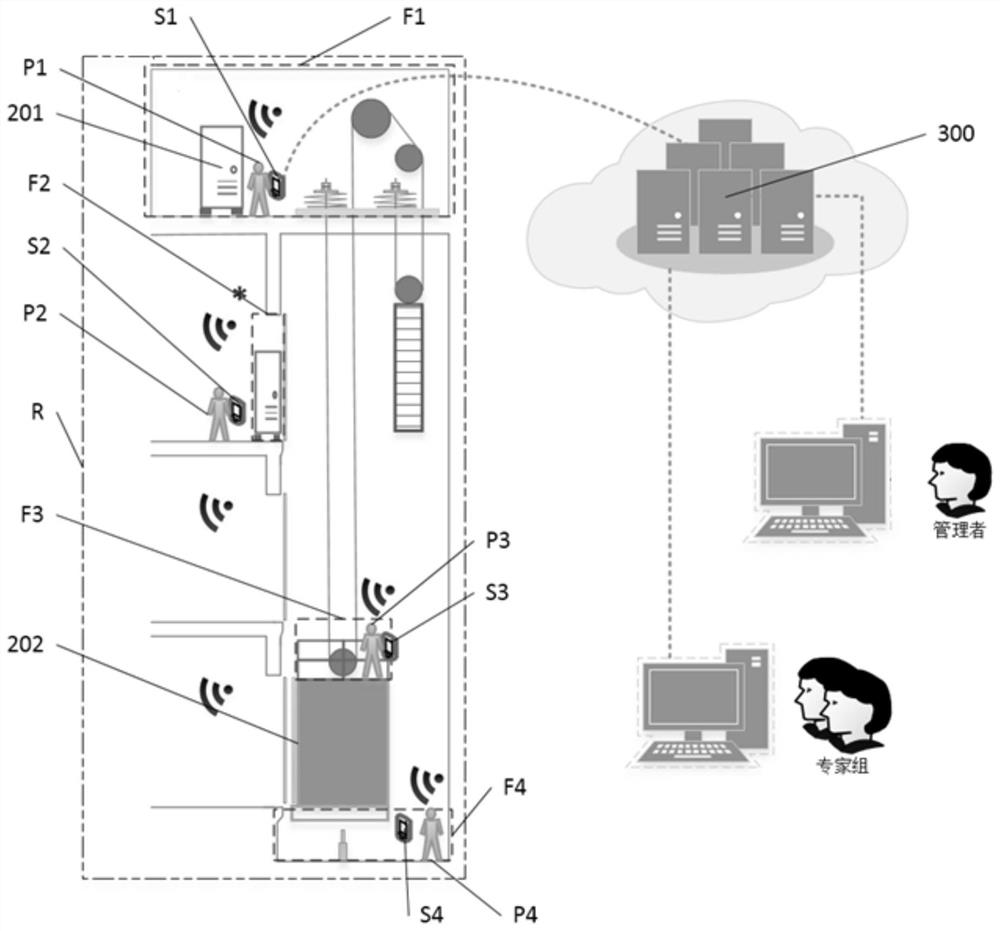

[0085] like figure 1 As shown, the elevator maintenance system includes portable components S1-S4, maintenance control equipment, short-distance card reader and controller;

[0086] The portable component has identity information and operation information on it;

[0087] The maintenance control equipment and the short-distance card reader are arranged in functional areas F1-F4;

[0088] The functional area is an area where non-elevator professionals are prohibited from entering;

[0089] Both the maintenance control equipment and the short-distance card reader communicate with the controller;

[0090] When a portable component enters a set position in a functional area, the proximity card reader in the functional area can read the identity information and operation information of the portable component and send it to the controller;

[0091] The controller, according to the received identity information and operation information of the portable parts sent by the short-dista...

Embodiment 2

[0104] Based on the elevator maintenance system of Embodiment 1, a remote card reader is set in the identification area R of the elevator;

[0105] The identification area R is the space where the elevator equipment is located and the landing waiting space, including the landing area, the shaft and the functional area;

[0106] Each remote card reader communicates with the controller;

[0107]The remote reader communicates wirelessly with portable components within its range;

[0108] Portable components S1-S4 are pre-stored with identity information and operation information;

[0109] The identity information includes the unique identification code of the portable part and the working identity of the corresponding elevator professionals P1-P4;

[0110] The operation information includes at least one of the number of elevators that need to be maintained for this operation, the work place of each elevator, the work item, and the work time;

[0111] When a portable component ...

Embodiment 3

[0118] Based on the elevator maintenance system in Implementation 1, the short-distance card reader is provided with a card slot;

[0119] When there is no portable part inserted in the card slot of a short-distance card reader, the identity information and operation information of the portable part cannot be read by the short-distance card reader and sent to the controller, and the controller prohibits passing the short-distance The maintenance control equipment set in the functional area where the card reader is located enables the elevator to run (for example, when no portable parts are inserted into the card slot of the short-distance card reader in the car top space, the up and down control function of the car top maintenance control equipment is prohibited );

[0120] When a portable part is inserted into the card slot of a short-distance card reader, the short-distance card reader can read the identity information and operation information of the portable part and send ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com