A self-detaching sewing device for an automatic sewing system

A sewing and self-unloading technology, which is applied in the direction of sewing equipment, threading devices, sewing machine components, etc., can solve the problems of complex structure, easy failure, and defective production of tribute needle machines, so that it is not easy to produce defective products and simplify the complexity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

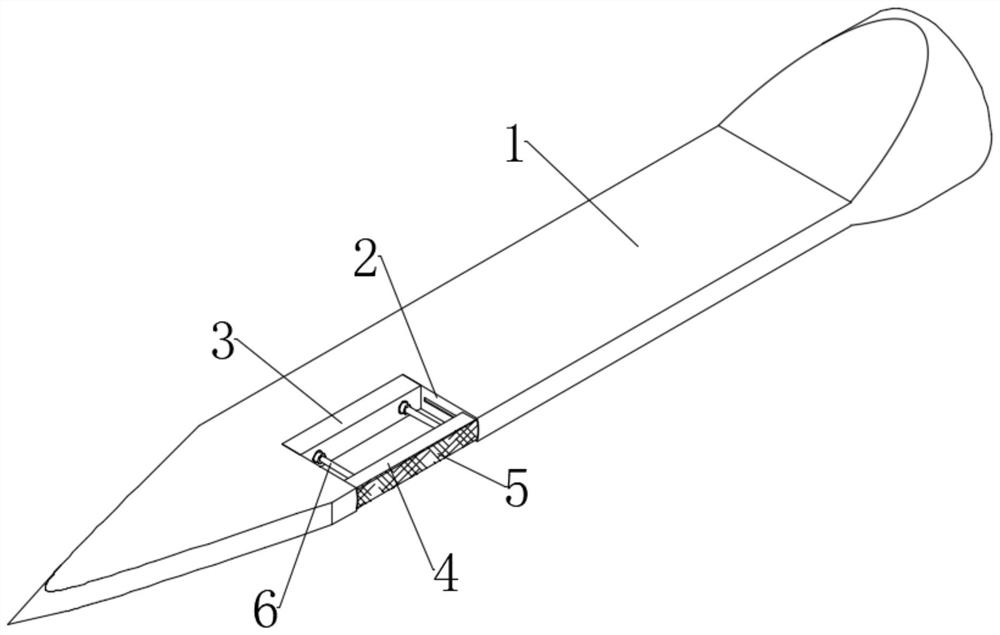

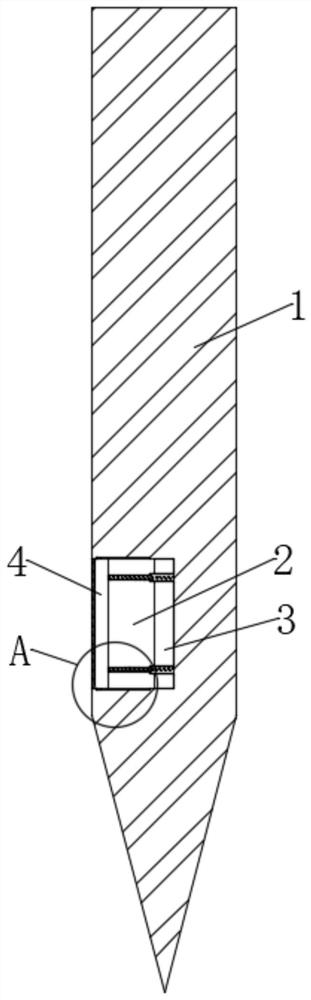

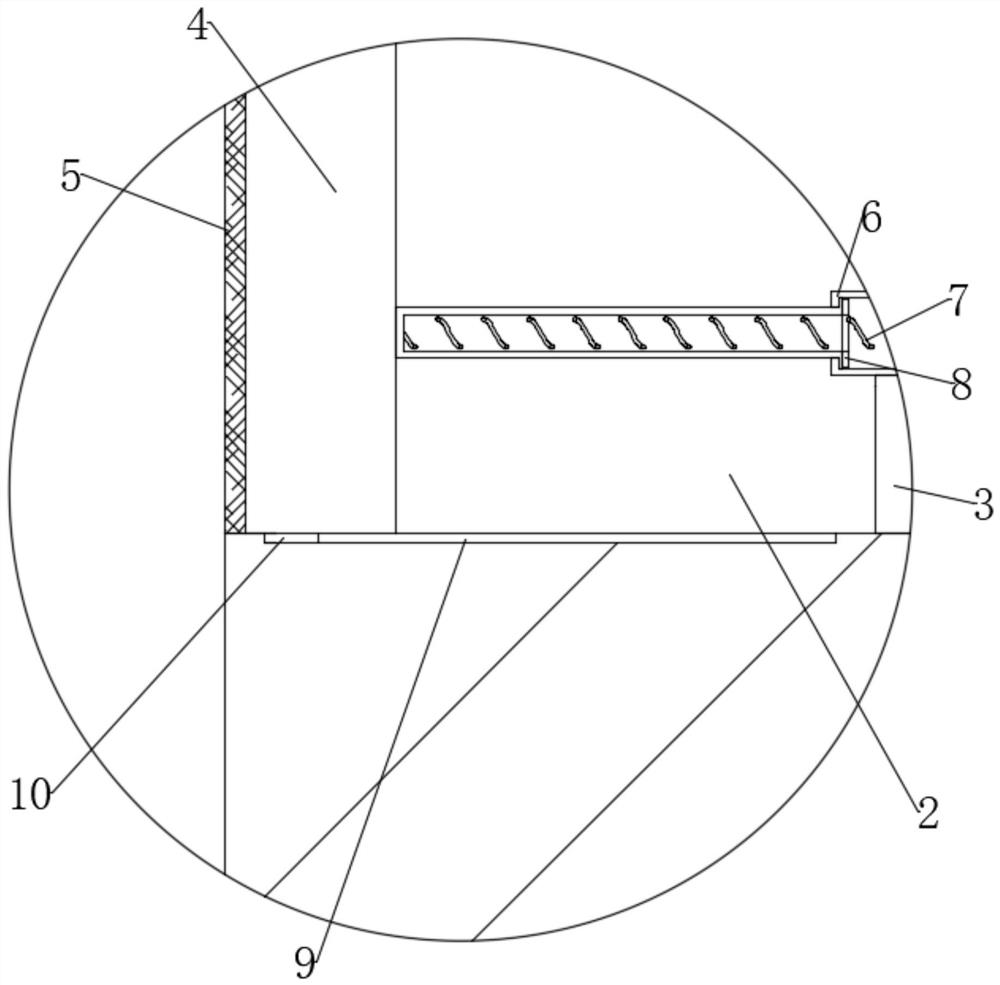

[0033] see Figure 1-3, a self-detachable sewing device for an automatic suture system, including a sewing device and a suture thread, the sewing device includes a needle body 1, a movable groove 2 is dug on the side wall of the needle body 1, and the movable groove 2 is located on the needle body 1 On the needle tip side of the movable groove 2, a fixed magnetic block 3 matching itself is fixedly connected to the side wall of the movable groove 2, and an electromagnetic block 4 matching itself is slidably connected in the movable groove 2, between the electromagnetic block 4 and the side wall of the movable groove 2 A pair of telescopic tubes 6 are fixedly connected between them. The telescopic tubes 6 are divided into two parts, the movable end and the fixed end. The fixed end runs through the fixed magnetic block 3 and is fixedly connected with the side wall of the movable groove 2. 6 is plugged with a compression spring 7, the two ends of the compression spring 7 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com