Underground engineering supporting structure and construction method thereof

A technology for supporting structure and underground engineering, applied in underground chambers, shaft equipment, shaft lining and other directions, can solve the problems of high construction risk, high construction cost, complex construction, etc., to reduce risks, simple construction methods, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

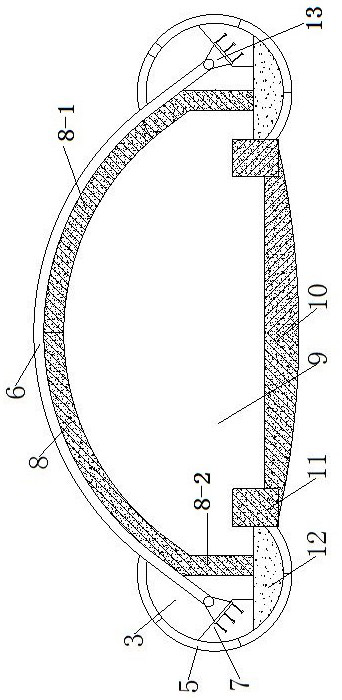

[0044] Embodiment 1: a kind of underground engineering support structure, such as figure 1 As shown, it includes two leading pilot tunnels 3 obtained through underground excavation construction, an arch structure 4 and a floor structure are obtained by construction between the two leading pilot tunnels 3, and the floor structure is arranged below the arch structure 4; the preceding pilot tunnels 3 is provided with a combined lining 5, and the arch structure 4 and the floor structure are connected with the combined lining 5. The arch structure can support the soil to be excavated, which is convenient for excavating the soil under the protection of the arch structure during construction, and avoids the collapse of the soil during the excavation process. The two combined linings are connected with the two ends of the arch structure correspondingly. Reinforce and support the ends of the arch structure and transfer and share loads for the arch structure.

[0045] The arch structur...

Embodiment 2

[0051] Embodiment 2: a kind of construction method of underground engineering support structure, comprises the steps:

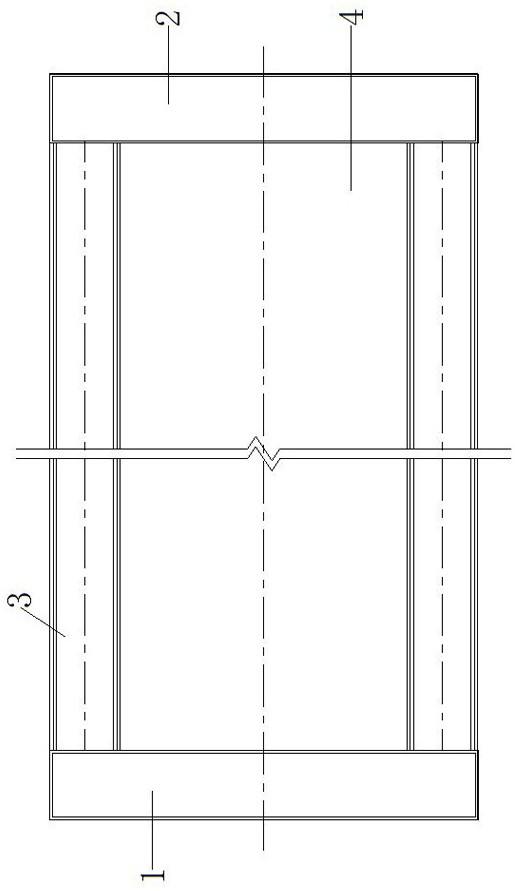

[0052] S1, construction of originating shaft 1 and receiving shaft 2: as figure 2 As shown in Fig. 1, select appropriate positions at both ends of the construction site where the underground project is to be constructed to excavate the originating shaft 1 and the receiving shaft 2 respectively;

[0053] The setting of originating shaft 1 and receiving shaft 2 can facilitate the hoisting in and out of excavation equipment, equipment jacking construction, and material in and out. During specific construction, the originating shaft 1 and receiving shaft 2 can be set according to the construction requirements of the roadheader. size of.

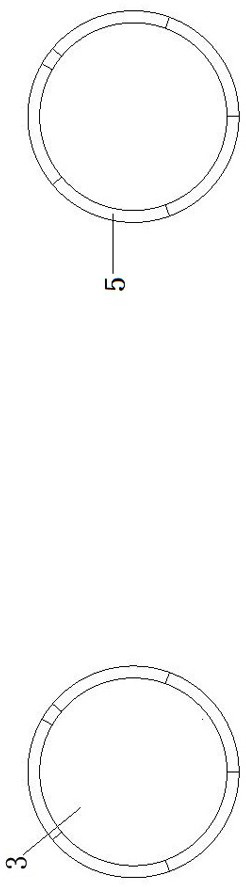

[0054] S2, the construction of the first pilot tunnel 3: if image 3 As shown, the leading pilot tunnel 3 is respectively excavated between the originating shaft 1 and the receiving shaft 2, and a combined lining 5 is laid on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com