A system and method for coordinating cold-regeneration and hot-regeneration steam supply

A technology of steam supply system and reheated steam, which is applied in the field of steam turbines and can solve the problems of unable to extract a large amount of steam extraction, increase of steam extraction for heating, poor economy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

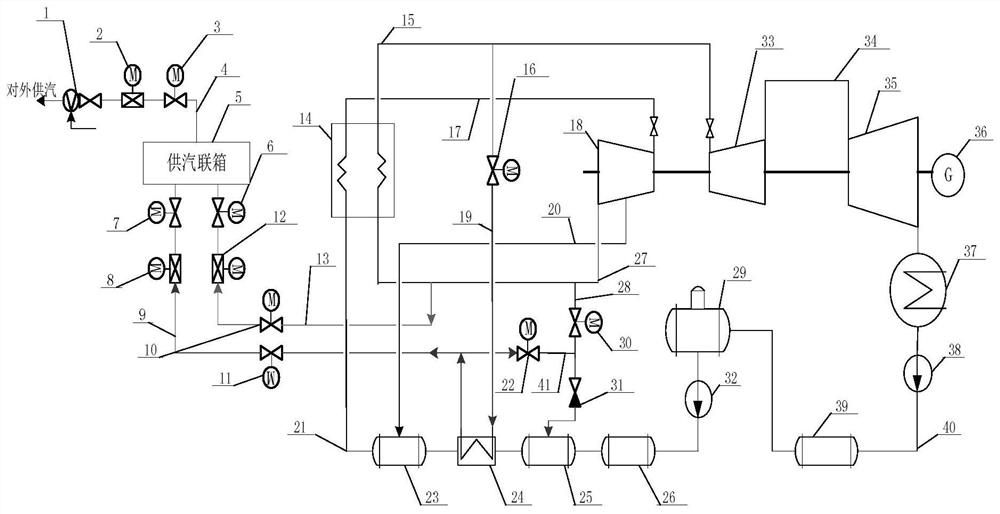

[0031] A cold reheating and reheating cooperative steam supply system of this embodiment is arranged in a thermal power generating set for adjusting the steam supply to the steam supply header 5; the thermal power generating set includes a boiler 14, a main steam pipeline 17, High pressure cylinder 18, medium pressure cylinder 33, medium and low pressure connecting pipe 34, low pressure cylinder 35, generator 36, condenser 37, condensate pump 38, condensate water pipeline 40, low pressure heater 39, deaerator 29, feed water pump 32, High plus 3 (26), high plus 2 (25), high plus 1 (23), water supply pipeline 21, reheat steam pipeline hot section 15, reheat steam pipeline cold section 27, cold section extraction pipeline 13, supply Steam header 5 and external steam supply pipeline 4.

[0032] Among them, the first-stage extraction pipeline 20 and the second-stage extraction pipeline 28 of the high-pressure cylinder 18 are connected to the steam side inlets of the high-pressure c...

Embodiment 2

[0037] This embodiment adopts the cold reheating and hot reheating cooperative steam supply system in Embodiment 1, and its steam supply method includes the following specific steps:

[0038] 1) When the steam supply header 5 supplies heat to the outside, it enters the working state 1, the cold section extraction pipeline 13 is put into operation, the hot section extraction pipeline 19 exits, and the first cold re-extraction cut-off door 10 and the second cold section are opened. The re-extraction cut-off door 6 is used to control the steam extraction volume on the cold section extraction pipeline 13 by adjusting the cold re-extraction valve 12. After the steam enters the steam supply header 5, the external steam supply cut-off door 3 is opened, and the external steam supply is reduced. The temperature and pressure reducer 1 adjusts the pressure and temperature of the external steam supply, and the external steam supply control valve 2 coordinates with the cold re-extraction st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com