Sample cooler for petrochemical industry

A petrochemical and cooler technology, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of sample medium clogging, increase the flow resistance of sample medium with high viscosity, and reduce clogging , Improved functionality, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

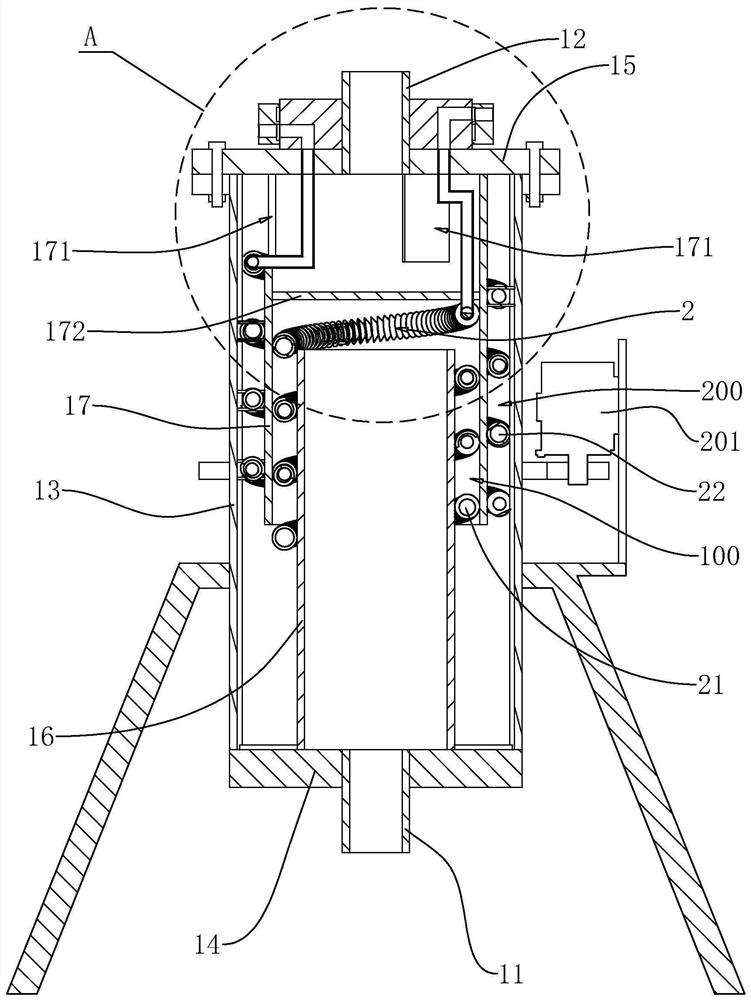

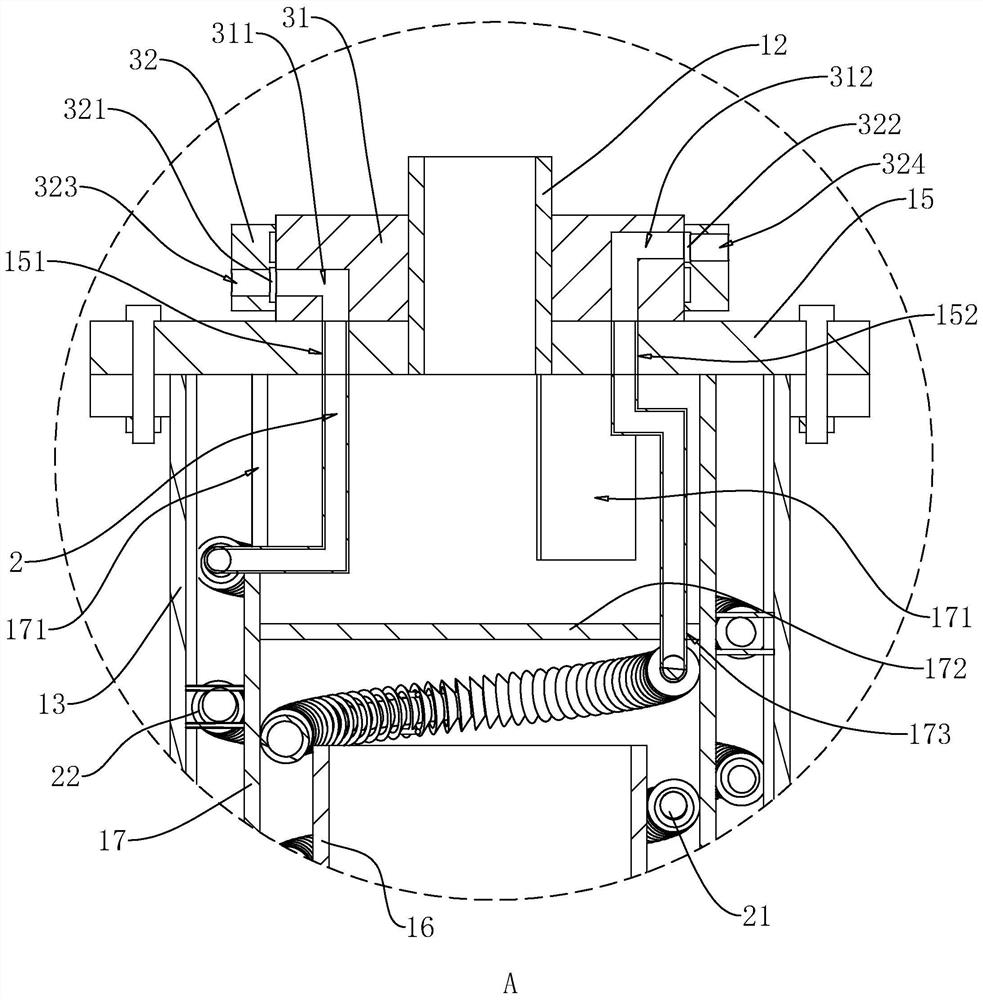

[0041] The following is attached Figure 1-7 The application is described in further detail.

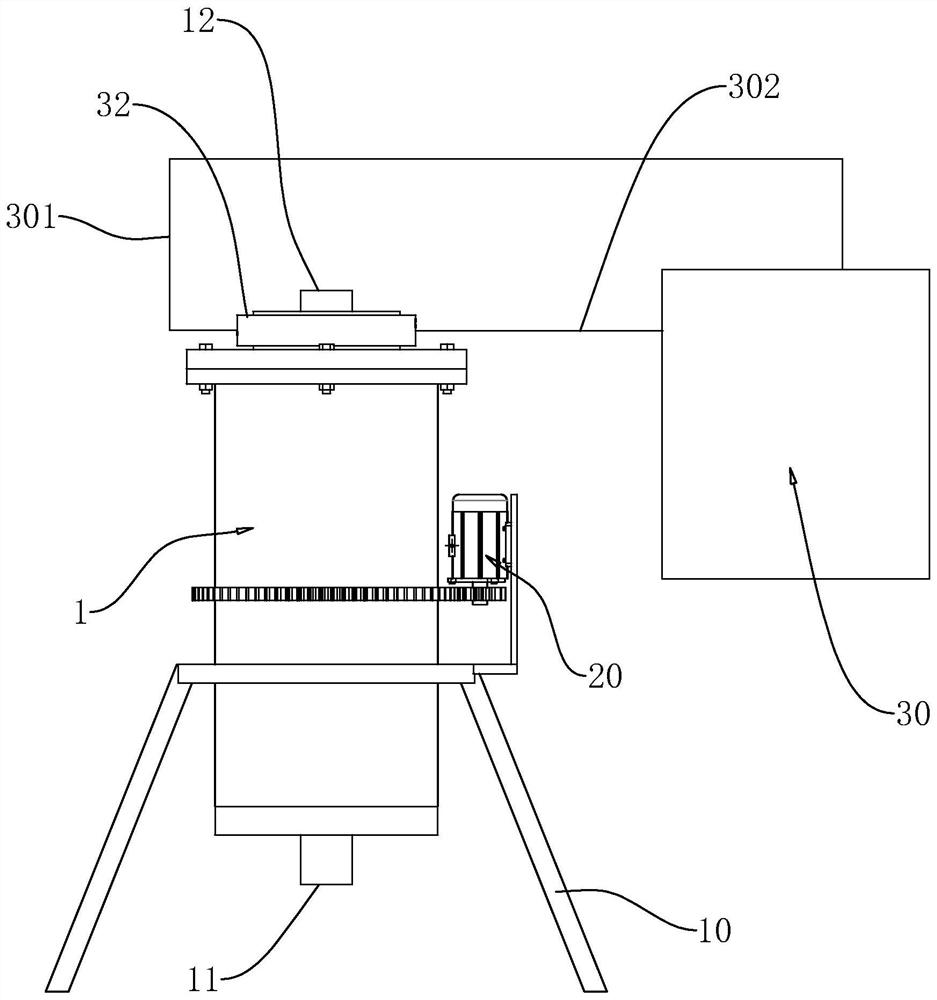

[0042] The embodiment of the application discloses a sampling cooler for petrochemical industry. refer to figure 1 , figure 2 The petrochemical sampling cooler includes a frame 10, a cooling cylinder 1 rotatably arranged on the frame 10, and a drive assembly 20 that drives the cooling cylinder 1 to rotate around its own axis; the two ends of the cooling cylinder 1 are closed, and the cooling cylinder 1 is equipped with There is a coil pipe 2, which is connected to an external condensed water circulation device 30, a feed pipe 11 is provided at one end of the cooling cylinder 1, and a discharge pipe 12 is provided at the other end of the cooling cylinder 1.

[0043] The sample medium enters the cooling cylinder 1 from the feed pipe 11 , during which the sample medium exchanges heat with the coil pipe 2 passing through condensed water, thereby reducing the temperature of the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com