A kind of NdFeB magnetic coil chamfer detection mechanism

A detection mechanism, NdFeB technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to ensure the close fit of the chamfers, large detection errors, etc., and achieve the effect of improving reliability and reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

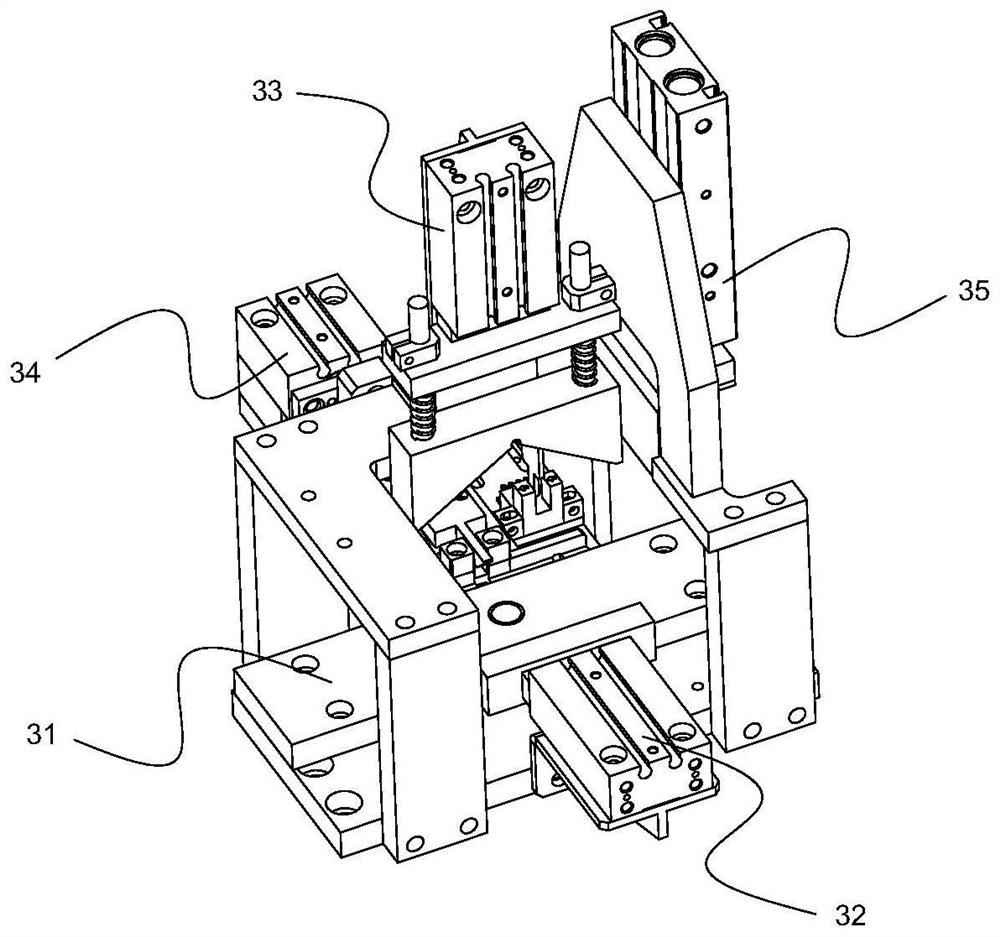

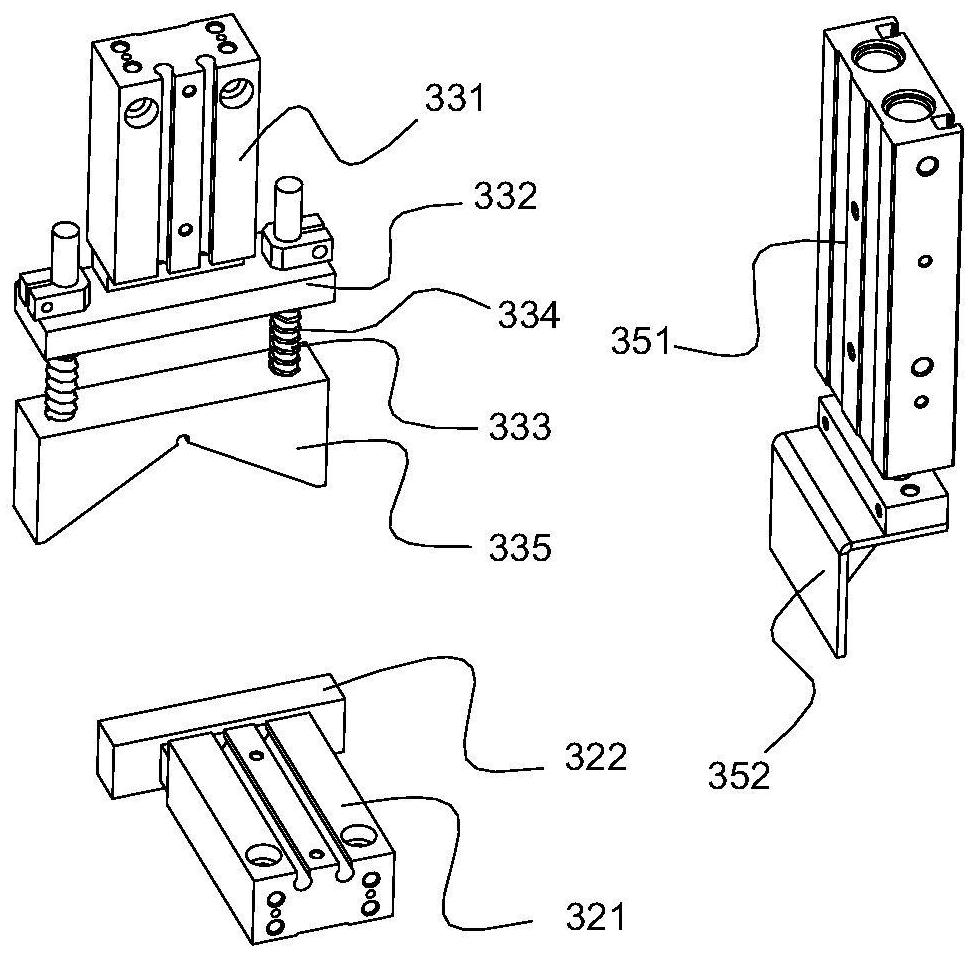

[0017] like figure 1 As shown, a neodymium-iron-boron magnetic coil chamfer detection device includes a conveying track 31, a side pressing mechanism 32, an upper pressing mechanism 33, a chamfering detection mechanism 34 and a blocking mechanism 35. The conveying track 31 is inclined and the discharge end is at the bottom. The side of the feeding end of the conveying track 31 is respectively provided with a side pressing mechanism 32 and a chamfering detection mechanism 34, and the upper portion of the feeding end of the conveying track 31 is provided with an upper pressing mechanism 33. . A blocking mechanism 35 is provided at the discharge end of the conveying track 31 . The side pressing mechanism 32 is used to press the side of the magnetic coil; the upper pressing mechanism 33 is used to press the magnetic coil on the conveying track 31 from the upper part of the magnetic coil; the blocking mechanism 35 is used to press the upper pressing mechanism 33 The magnetic coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com