Intelligent barrel inspection equipment for chemical equipment and barrel inspection method

A technology for chemical equipment and inspection equipment, which is applied in the field of intelligent inspection equipment for cylinders used in chemical equipment and cylinder inspections. It can solve the problems of poor objectivity, high labor costs, surface pits, etc., and achieve smooth inspection processes and low labor costs. Low, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

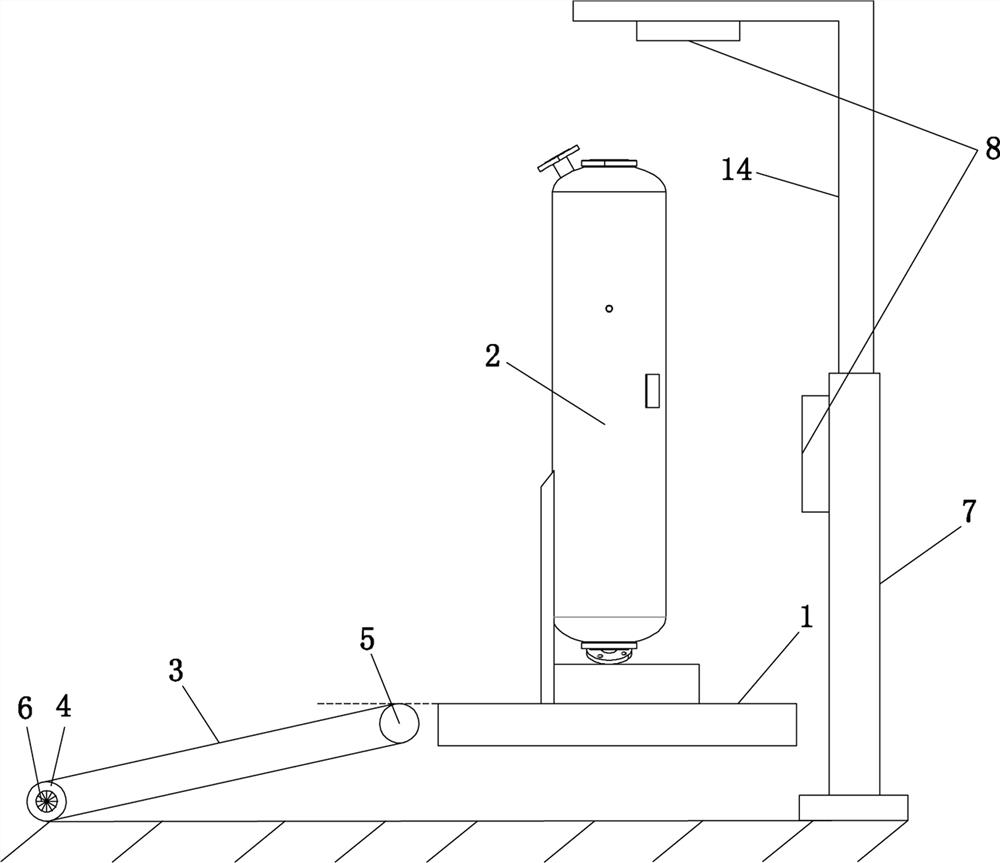

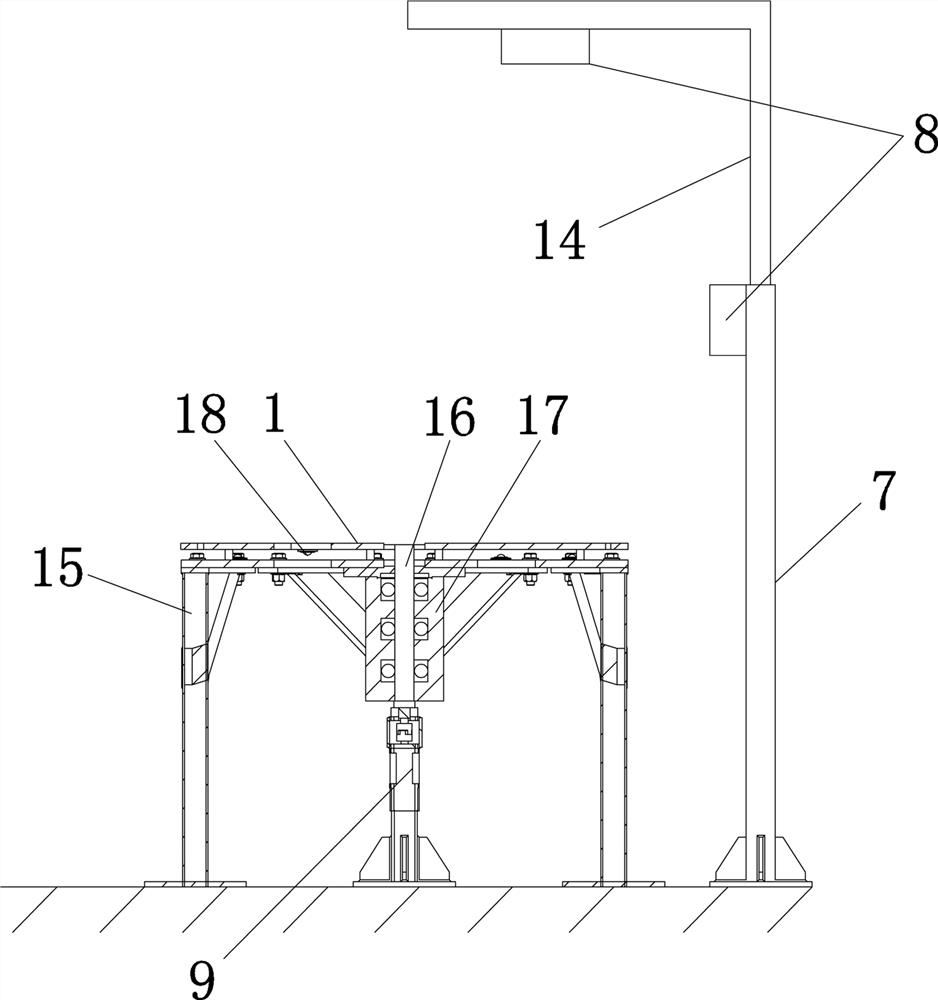

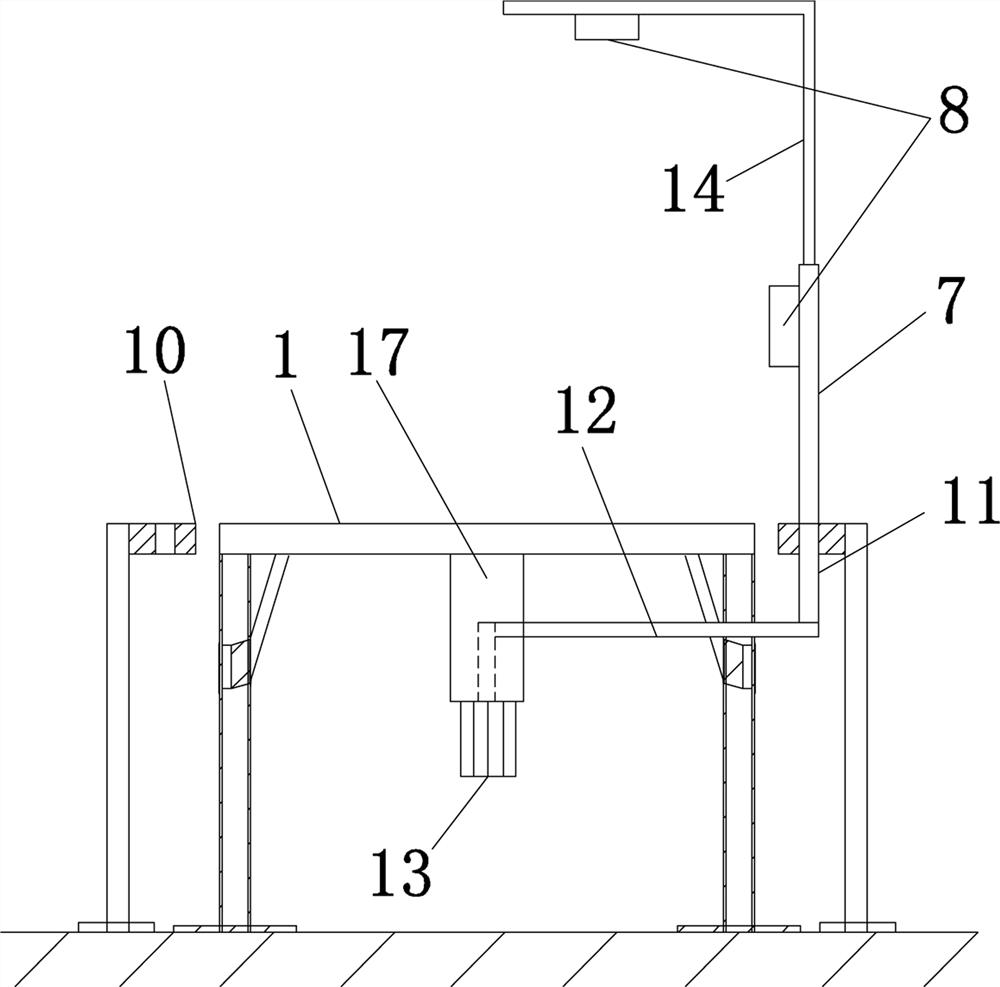

[0064] An annular track 10 is arranged on the outer edge of the stage 1, and a slider 11 is arranged in the annular track 10. The upper part of the slider 11 drives the support rod 7 thereon. The shaft drives the guide rod 12 to rotate, and then the guide rod 12 is connected with the bottom of the slide block 11 to drive the slide block 11 to slide along the circular track 10. At this time, the carrier 1 does not move, and the support rod 7 rotates. The linear camera 8 collects images of the outside of the barrel 2 line by line; in this embodiment, the second rotating motor 13 can also be arranged at the bottom of the stage 1 through the sleeve 17 .

[0065] In the present invention, in order to obtain a full range of images, the support rod 7 is an inverted L shape, and a linear camera 8 is arranged between the vertical side and the horizontal side of the support rod 7 and the corresponding surface of the cylinder body 2 .

[0066] In the present invention, since the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com