Production scheduling management method based on logic priority principle by utilizing computer

A management method and computer technology, applied in the fields of production scheduling management and intelligent manufacturing, can solve the problems of scientificity, efficiency, flexibility and sharing, and less inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

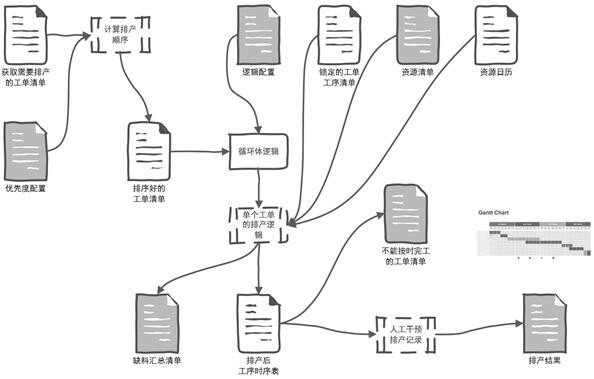

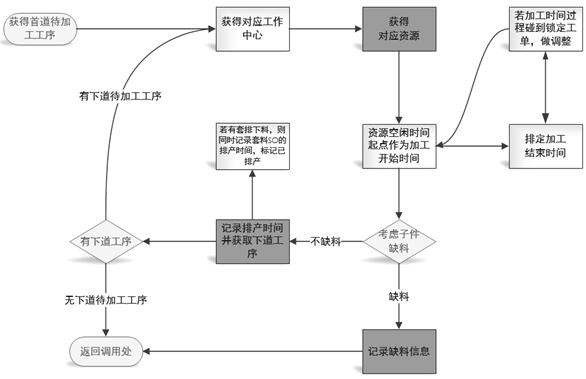

[0045] As shown in the accompanying drawings, the present invention relates to a production scheduling management method based on the principle of logical priority using a computer. All work orders are issued and input into the computer system, including finished work orders and semi-finished work orders, and are input according to Priority is numbered, each work order is given a priority number, and the minimum priority number is the principle of priority, which is identified by computer software; production scheduling starts from the entered work order, according to the size of the priority number, Scheduling from small to large; and only schedule the work orders that are released and started, starting from the finished work order with the smallest priority number; to be precise, the finished work order with the highest priority; when all production is scheduled At the end, output a production scheduling list, including work order number, process number, processing material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com