Dust falling shakeout machine

A technology for shakeout and dust reduction, which is applied to the cleaning/processing machinery of casting materials, casting molding equipment, manufacturing tools, etc., can solve the problems of time-consuming and laborious, unified use, and inability to secondary filtration of sand and gravel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings.

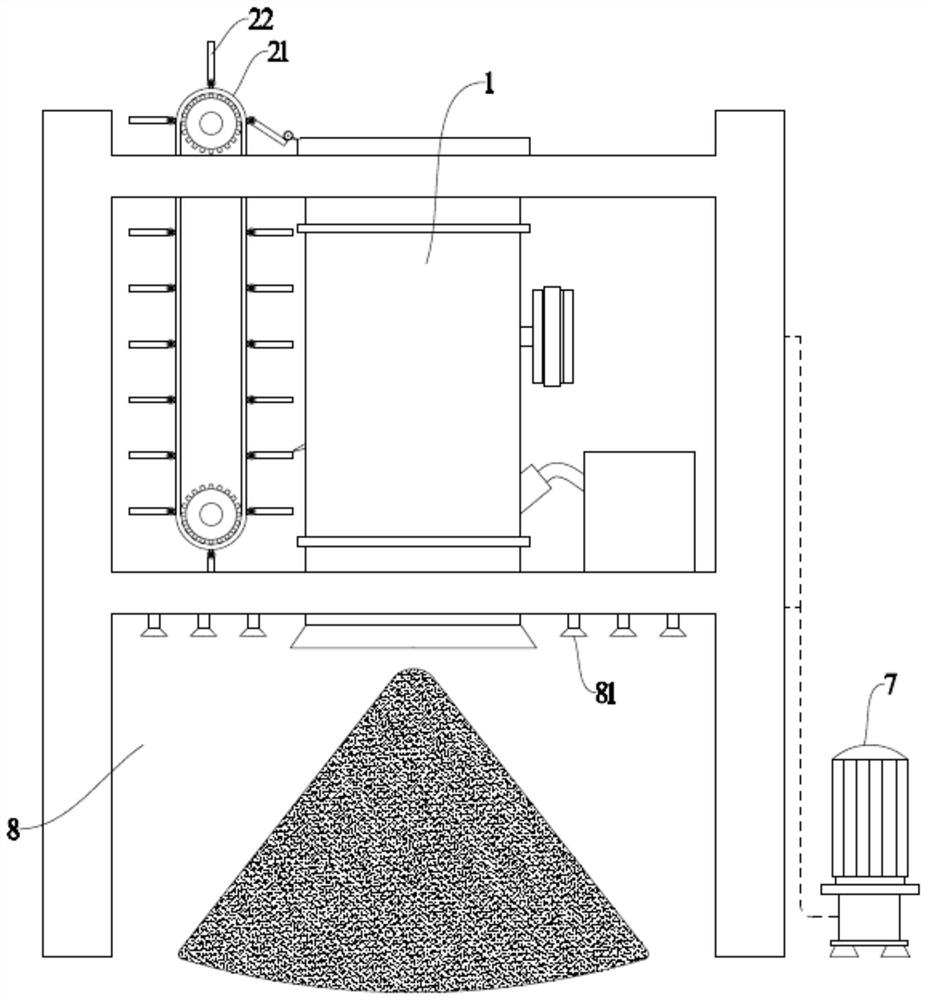

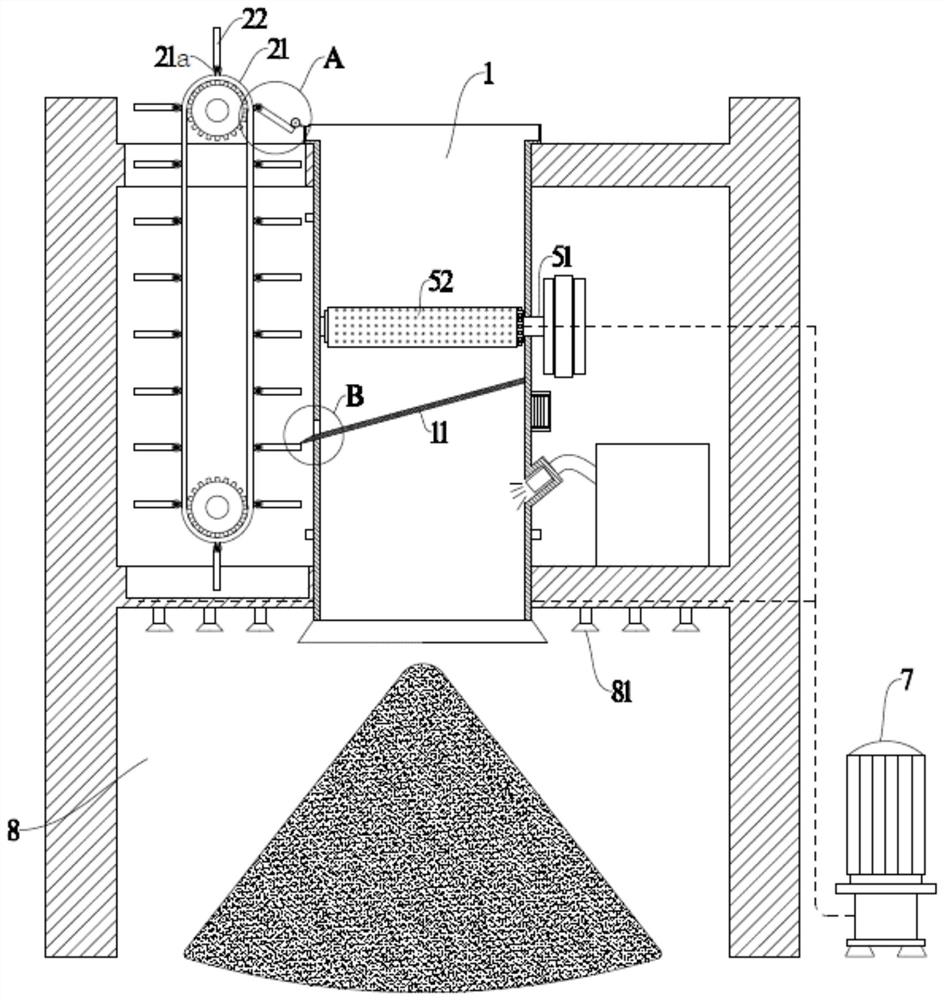

[0039] During specific implementation: if Figure 1 to Figure 6 As shown, a dust-reducing and sand-falling machine includes a body 1 and a sand and gravel circulation assembly installed on the body 1; a coarse sand filter 11 is obliquely placed inside the body 1, and the body 1 is at the lower end of the coarse sand filter 11 There is a coarse sand outlet; the top of the sand circulation component is connected to the sand inlet on the top of the body 1, and the bottom of the sand circulation component is connected to the coarse sand outlet;

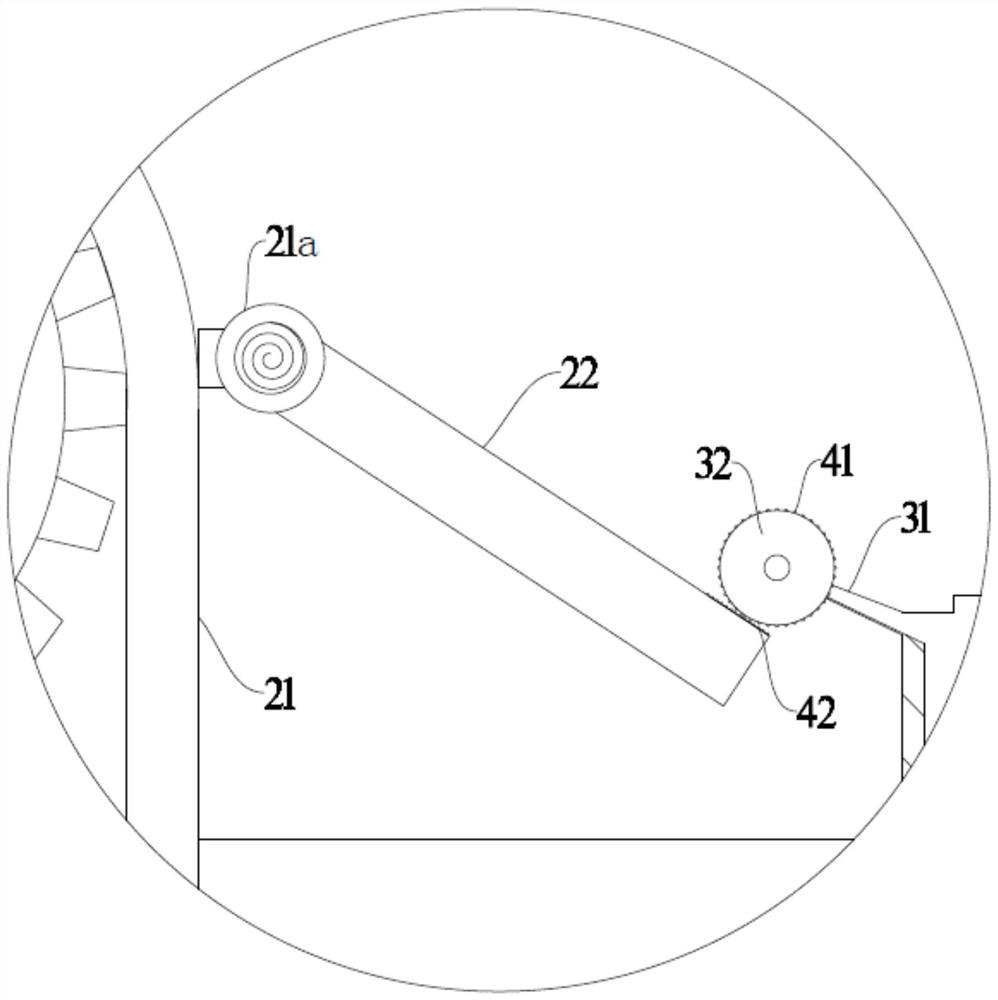

[0040] The gravel circulation assembly includes a vertically arranged conveying platform 21 and a plurality of circulating lifting plates 22; the conveying platform 21 is equidistantly provided with a plurality of bosses 21a; each of the circulating lifting plates 22 It is hinged on a boss 21a by a torsion spring, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com