Automatic feeding and discharging device based on digital control drilling machine for circuit board

A technology of automatic loading and unloading, CNC drilling machine, applied in positioning device, feeding device, boring/drilling, etc., can solve problems such as low efficiency, and achieve low efficiency, stable conveying, and prevention of offset jamming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

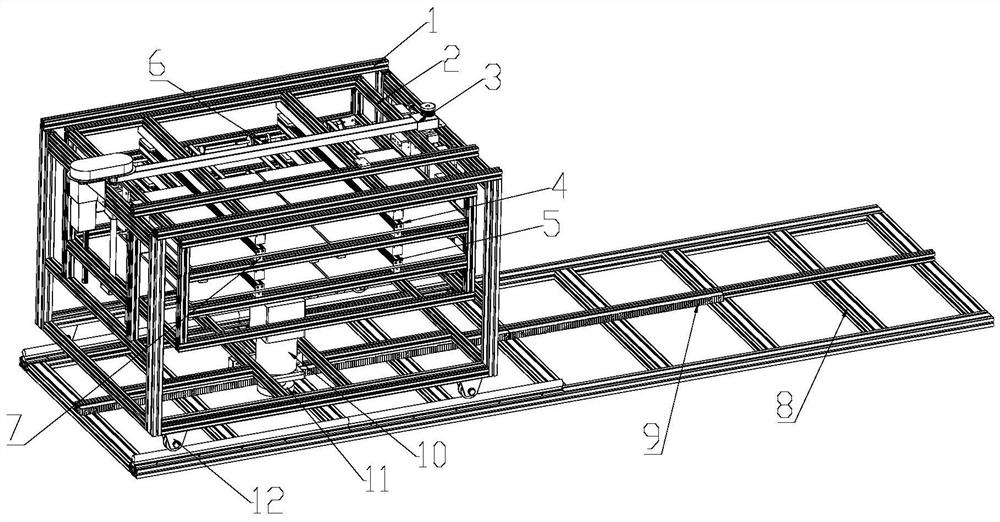

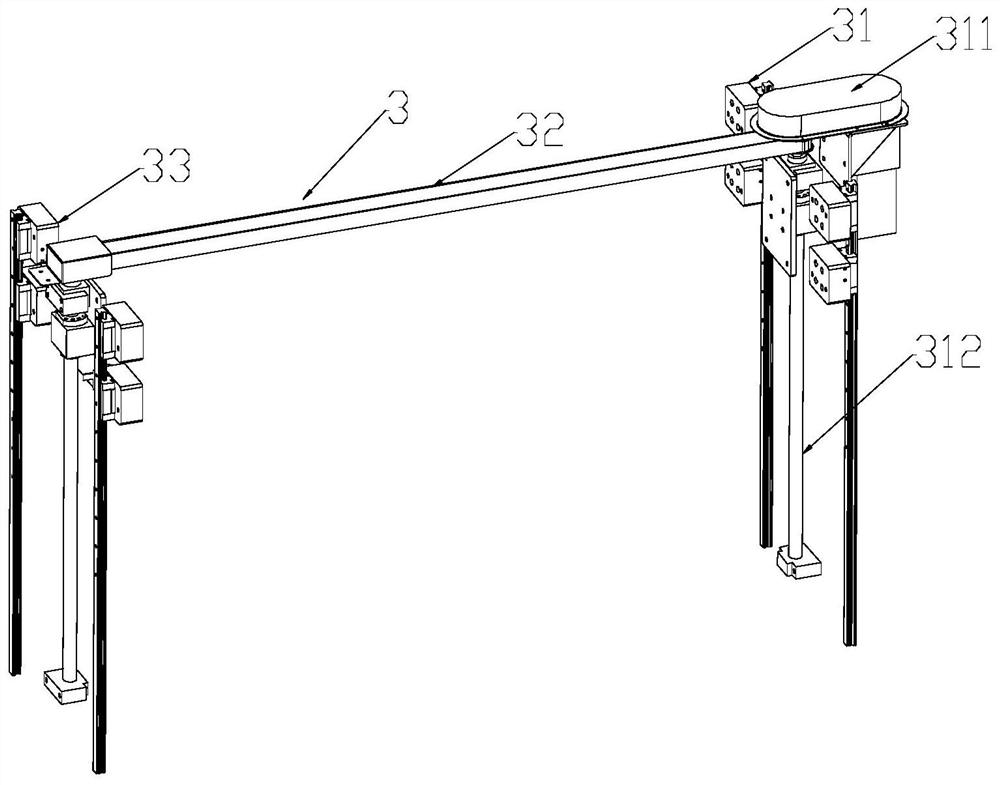

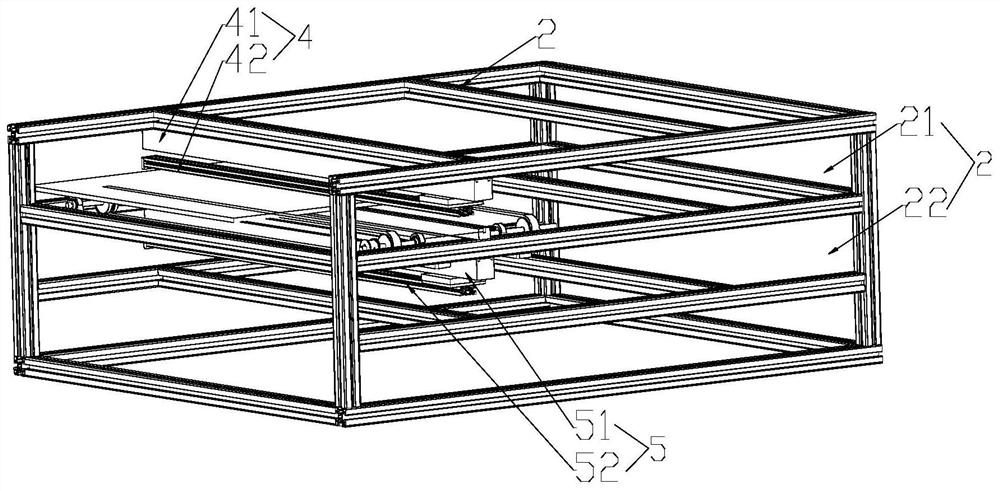

[0026] Embodiment one: as attached Figure 1-4As shown, the present invention discloses an automatic loading and unloading device based on a circuit board numerical control drilling machine, which includes a frame 1, a lifting unit 3, a support frame 2, a pushing unit 4, a pulling unit 5, a conveying unit Unit 6 and anti-deflection guide bar 7; wherein, the lifting unit 3 is fixedly arranged on the frame 1, the support frame 2 is fixedly arranged on the moving end of the lifting unit 3, and the conveying unit 6 is transversely Fixedly arranged on the support frame 2, the anti-deflection guide bar 7 is fixed laterally on the support frame 2 and kept at the same level as the moving end of the conveying unit 6 so that the circuit board is driven by the conveying unit 6 Move along the direction of the anti-deflection guide bar 7, and the pull-back unit 5 is fixed laterally on the support frame 2 above the conveying unit 6 so that the circuit board is driven by the pull-back unit 5...

Embodiment 2

[0031] Embodiment two: as attached Figure 1-4 As shown, the present invention discloses an automatic loading and unloading device based on a circuit board numerical control drilling machine. The automatic loading and unloading device based on a circuit board numerical control drilling machine also includes a base 8, a moving motor 10, a moving rack 9 and Mobile gear 11; the mobile rack 9 is fixedly arranged on the base 8, the mobile motor 10 is fixed on the bottom of the frame 1 and the drive shaft of the mobile motor 10 is provided with the mobile rack The moving gear 11 meshed with 9 makes the frame 1 move along the moving rack 9 driven by the moving motor 10 . In the embodiment of the present invention, the moving rack 9 is welded and fixed on the middle position of the base 8 horizontally, and the moving motor 10 is welded and fixed on the bottom of the frame 1 and the moving motor 10 The drive shaft is provided with a moving gear 11 meshed with the moving rack 9 . In t...

Embodiment 3

[0032] Embodiment 3: The present invention discloses an automatic loading and unloading device based on a circuit board numerical control drilling machine. Wherein, the push-in unit 4 also includes a push-in motor and a push-in screw; the push-in motor is fixed on the support frame 2 above the conveying unit 6, and one end of the push-in screw is fixed on the On the drive shaft of the push-in motor, the push-in cylinder 41 is threadedly arranged on the other end of the push-in screw rod so that the push-in cylinder 41 is pushed in vertically along the push-in screw rod under the drive of the push-in motor. Activity. In the embodiment of the present invention, when the present invention is powered on, the conveying unit 6 is fixed laterally on the support frame 2 so that the circuit board is driven by the conveying unit 6 to open along the support frame 2, that is, along the The direction of the anti-deflection guide bar 7 makes the leftmost end of the circuit board move to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com