Sheet transport mechanism for image forming device

一种纸张输送、图像的技术,应用在应用电荷图形的电记录工艺、应用电荷图形的电记录工艺的设备、电记录术等方向,能够解决输送性能降低、成本提高、色调剂量多等问题,达到简单结构、顺利输送、减轻硬度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

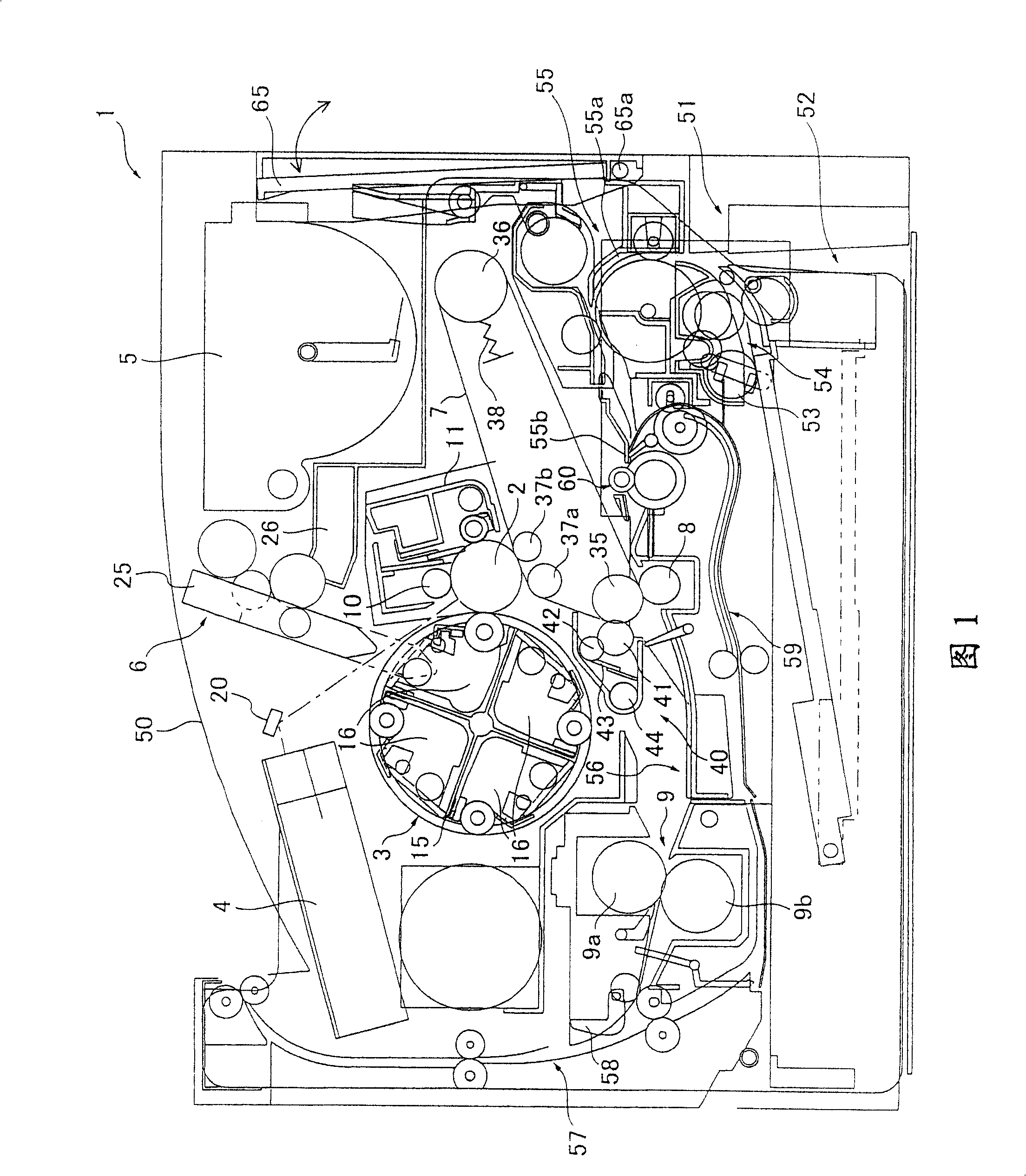

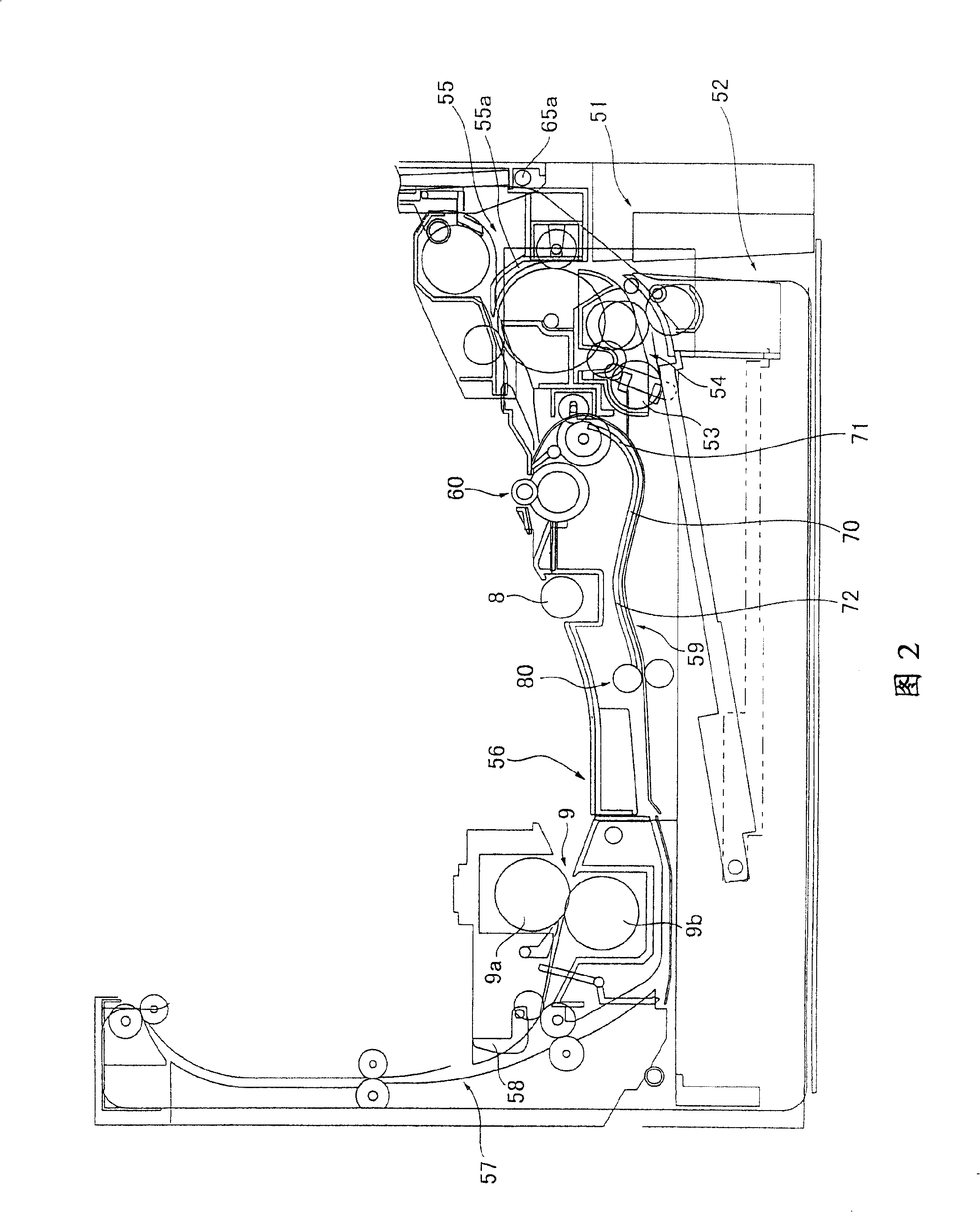

[0021] FIG. 1 shows a color printer 1 as a color image forming apparatus according to an embodiment of the present invention. In addition, this FIG. 1 is a schematic diagram for showing the arrangement of each component, and the specific configuration of each part is omitted.

[0022] the whole frame

[0023] The color printer 1 is connected to a computer or the like not shown, and is a device capable of printing a color image on paper based on image information sent from the computer or the like. Furthermore, in FIG. 1, the right side of the color printer 1 is the side where the operator operates. In the following, the right side of the apparatus in FIG. 1 is referred to as the operator's side, and the left side is referred to as the rear side.

[0024] A color printer 1 includes a photosensitive drum 2 , a rotary developing device 3 , a laser unit 4 , a toner container 5 , a toner supply device 6 , an intermediate transfer belt 7 , a secondary transfer roller 8 , and a fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com