A tank assembly and welding method

A welding method and tank technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult guarantee, cracking, random quality, etc., and achieve the effect of consistent and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

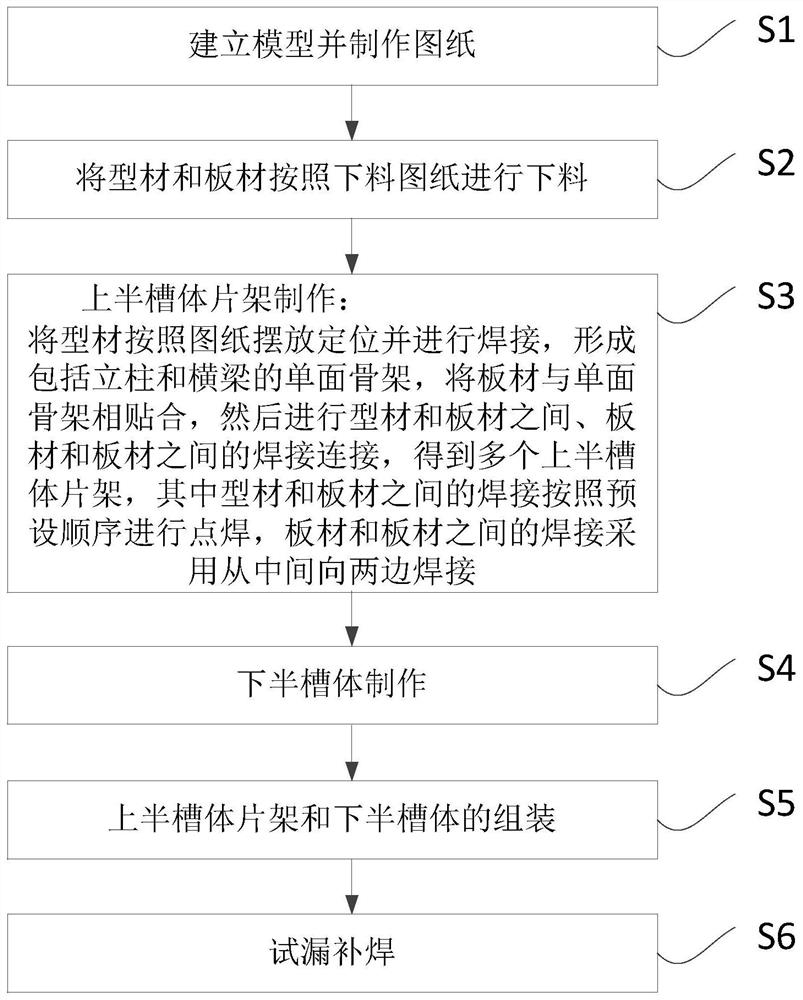

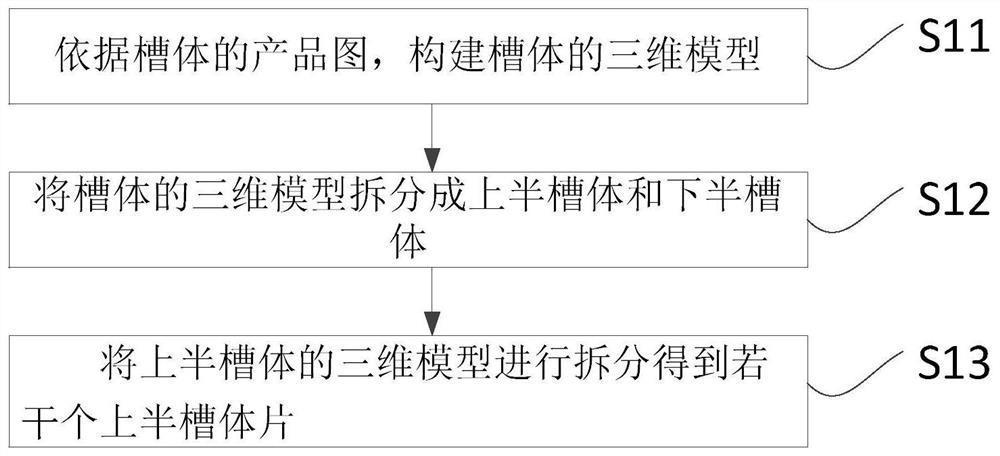

[0054] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

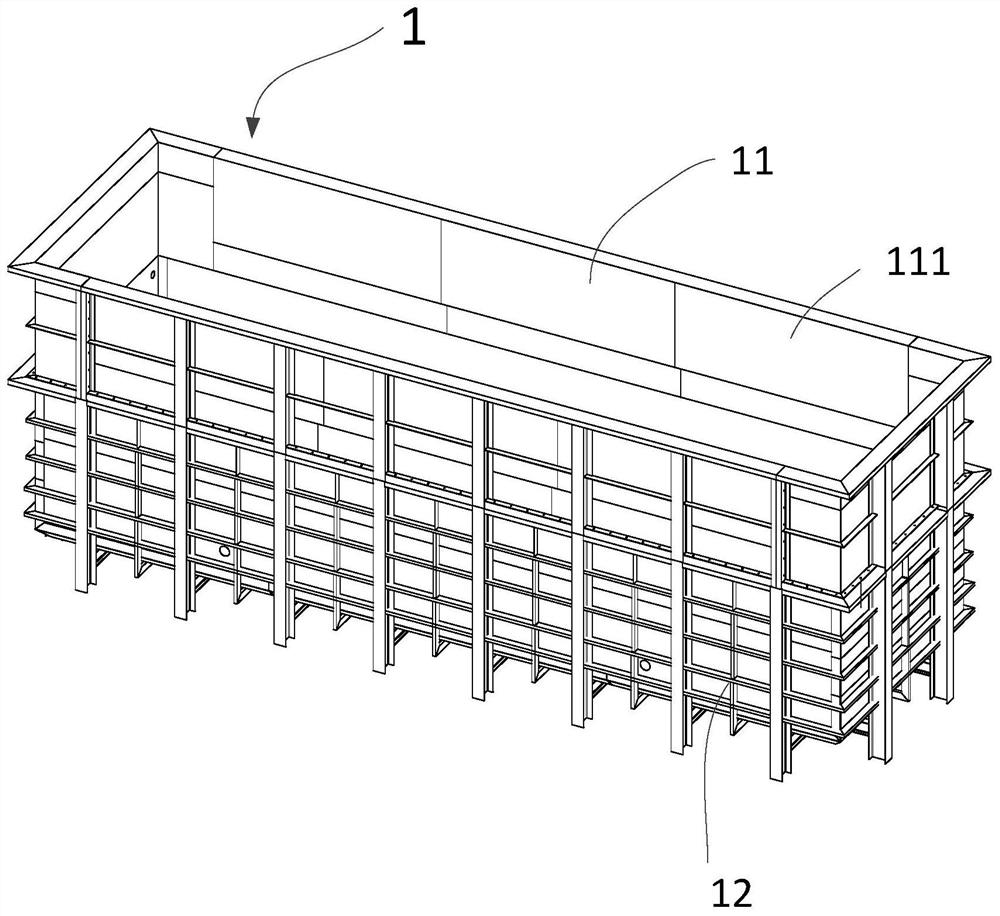

[0055] see figure 1 , figure 1 It is a structural schematic diagram of the tank body provided by the embodiment of the present invention. The tank body 1 in this embodiment includes an upper half tank body frame 111 and a lower half tank body 12, and the upper half tank body frame 111 and the lower half tank body 12 are assembled and welded by profiles and plates. Wherein, the profile can be H-shaped steel or I-beam, and the plate can be carbon steel plate or stainless steel plate.

[0056] Specifically, the upper half tank body 111 in this embodiment includes four, which are combined into the upper half tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com