Anisotropic magnetoresistive head assembling equipment and implementation method thereof

An anisotropic magnetic and assembly equipment technology, which is applied in the manufacture of flux-sensitive magnetic heads, magnetic recording heads, metal processing equipment, etc., can solve the problems of affecting material pressing, damaging the shell, being positioned and clamped, etc., to achieve convenient positioning clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

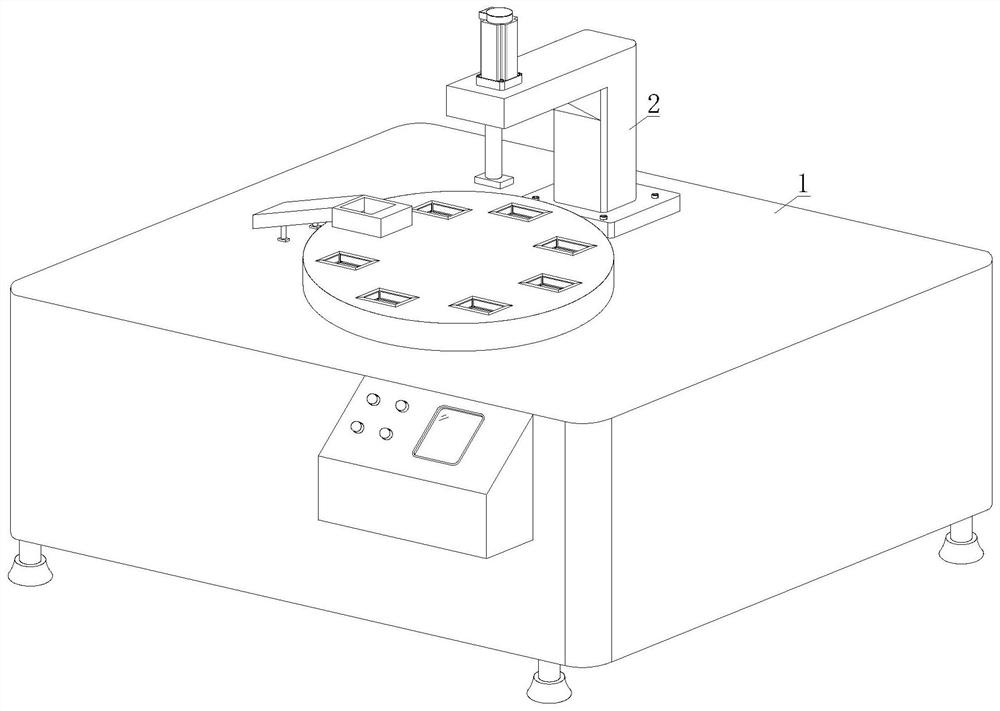

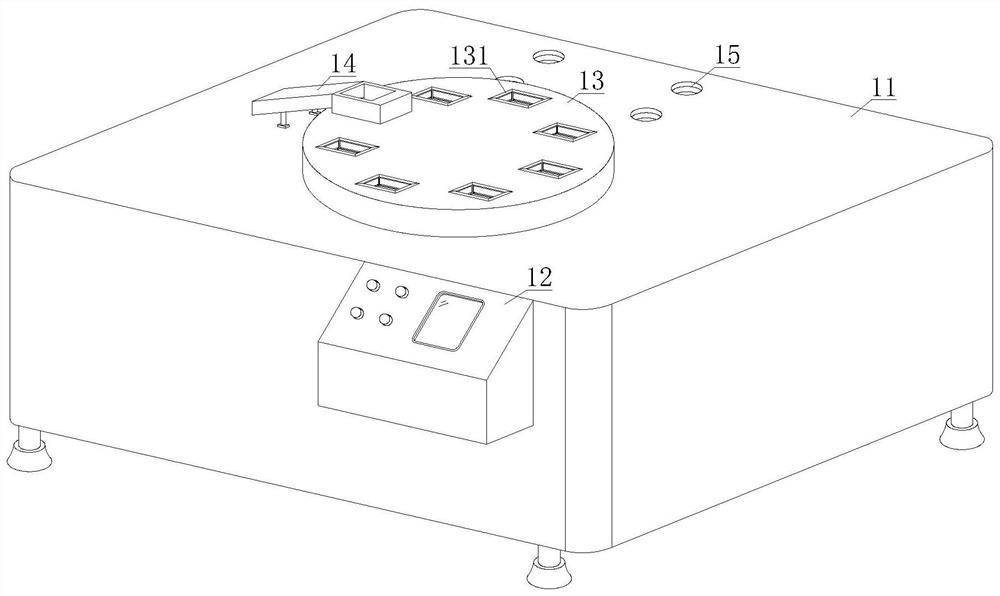

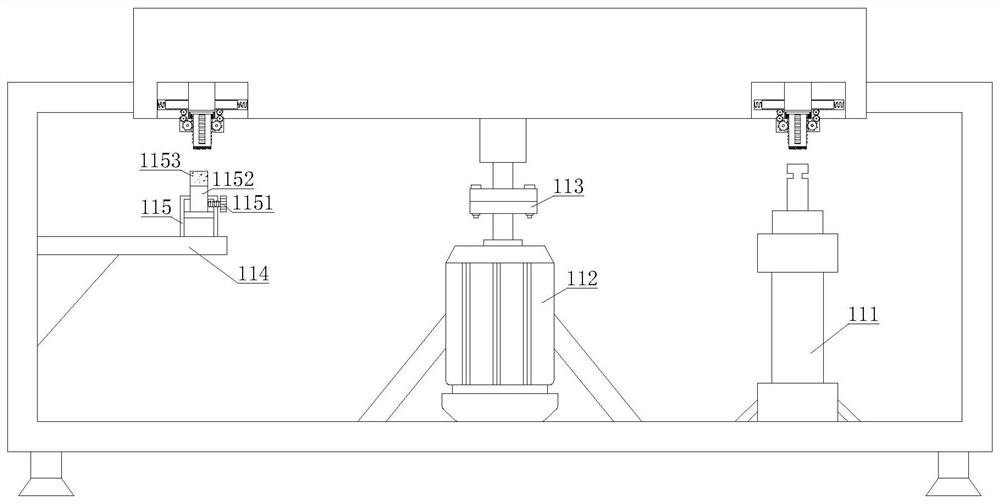

[0039] see Figure 1-2And 9, an anisotropic reluctance magnetic head assembly equipment, including a console 1 and a press-in device 2, the press-in device 2 is threaded on the upper end side of the console 1, and the console 1 includes a table 11, a manipulation device 12, Turntable 13, blanking device 14 and threaded hole 15, control device 12 is installed on the front side of table top 11, and rotating disk 13 is installed on the upper end of table top 11, and unloading device 14 is installed on the upper end side of table top 11, and unloading device One end of 14 is positioned at the vertical upper end turntable 13, and the upper end side of table top 11 is provided with threaded hole 15, and the inner chamber screw thread of threaded hole 15 is equipped with pressing device 2; Cylinder 23 and depression bar 24, the upper end of base plate 21 is equipped with right-angled frame 22, and the upper end side of right-angled frame 22 is equipped with first cylinder 23, and the...

Embodiment approach , 1 Embodiment approach

[0043] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing an anisotropic magneto-resistive magnetic head assembly device, comprising the following steps:

[0044] S01: After the material enters the inner cavity of the charging trough 131, the servo motor 112 rotates to drive the turntable 13 to rotate. When the turntable 13 is rotating, the chute 1323 at the lower end of the telescopic push rod 132 is slidingly connected with the second cylinder 111. Each rotation The angle is just at the lower end of the pressure rod 24;

[0045] S02: After the charging tank 131 rotates to the lower end of the pressure rod 24, the second cylinder 111 drives the telescopic push rod 132 to descend, and the telescopic push rod 132 descends to drive the first-stage gear 1331, the second-stage gear 1332 and the third-stage gear 1333 to rotate, The three-stage gear 1333 drives the first push rod 1312 t...

Embodiment 2

[0050] see Figure 1-2 And 9, an anisotropic reluctance magnetic head assembly equipment, including a console 1 and a press-in device 2, the press-in device 2 is threaded on the upper end side of the console 1, and the console 1 includes a table 11, a manipulation device 12, Turntable 13, blanking device 14 and threaded hole 15, control device 12 is installed on the front side of table top 11, and rotating disk 13 is installed on the upper end of table top 11, and unloading device 14 is installed on the upper end side of table top 11, and unloading device One end of 14 is positioned at the vertical upper end turntable 13, and the upper end side of table top 11 is provided with threaded hole 15, and the inner chamber screw thread of threaded hole 15 is equipped with pressing device 2; Cylinder 23 and depression bar 24, the upper end of base plate 21 is equipped with right-angled frame 22, and the upper end side of right-angled frame 22 is equipped with first cylinder 23, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com