Patents

Literature

41results about How to "Convenient positioning and clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

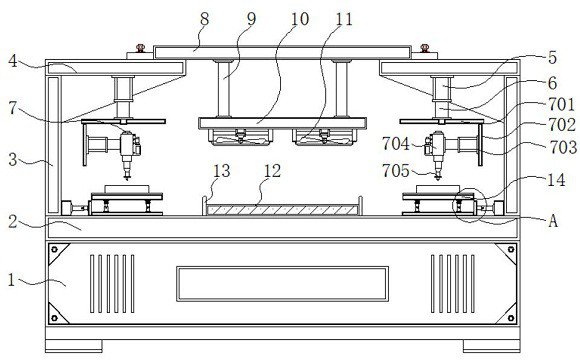

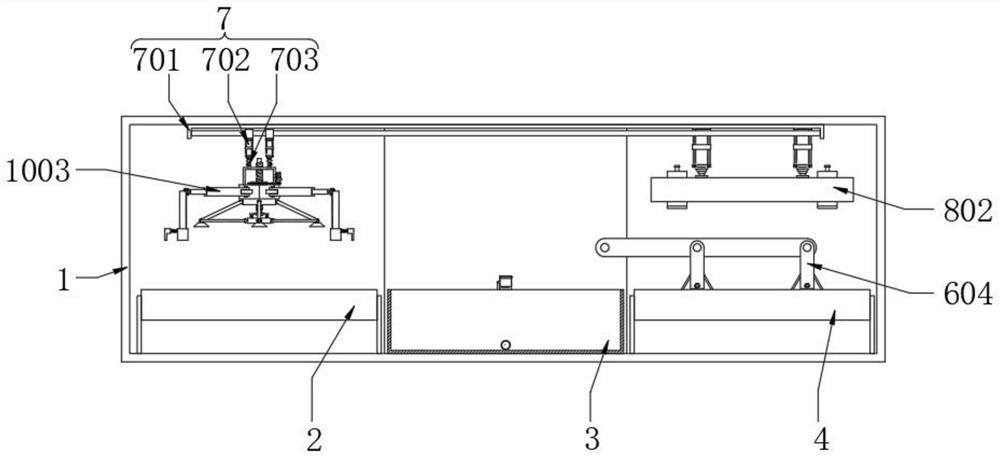

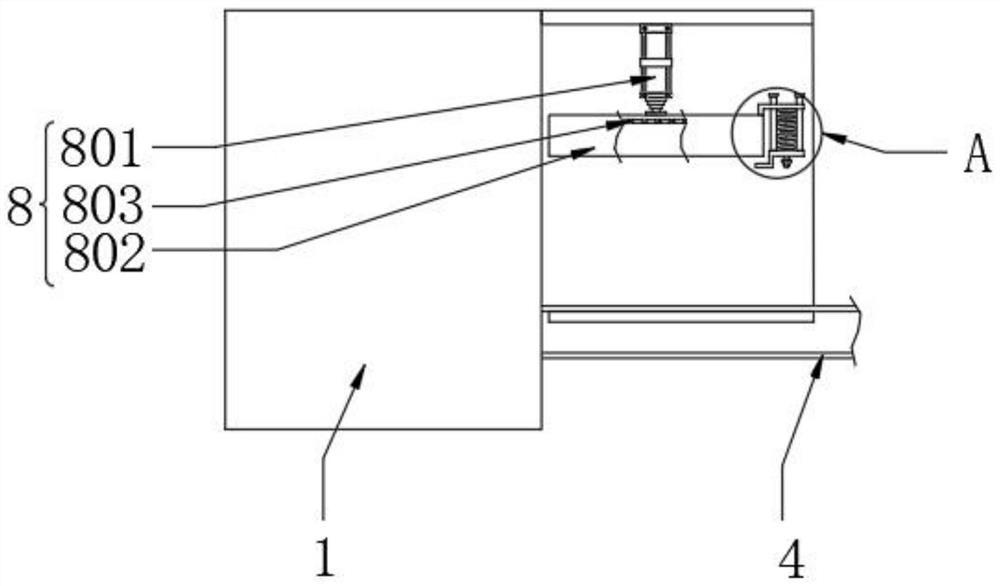

Drilling tool used for aluminum alloy hub

ActiveCN111558738AAvoid scratchesEasy to unloadFeeding apparatusPositioning apparatusHydraulic cylinderElectric machinery

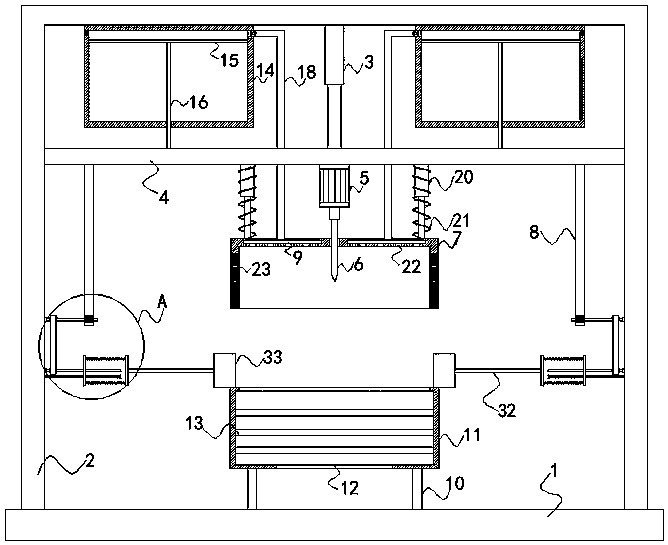

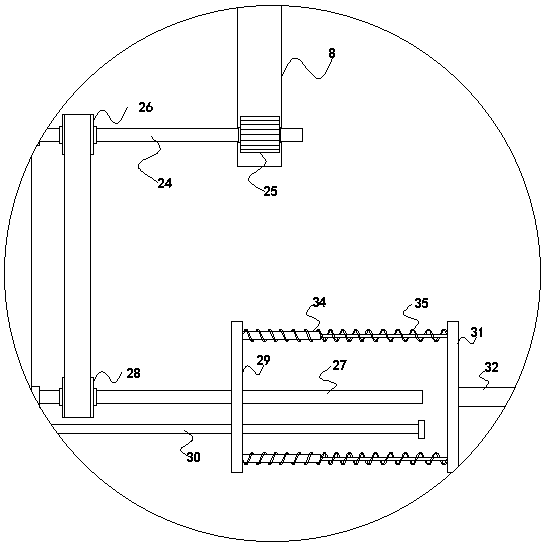

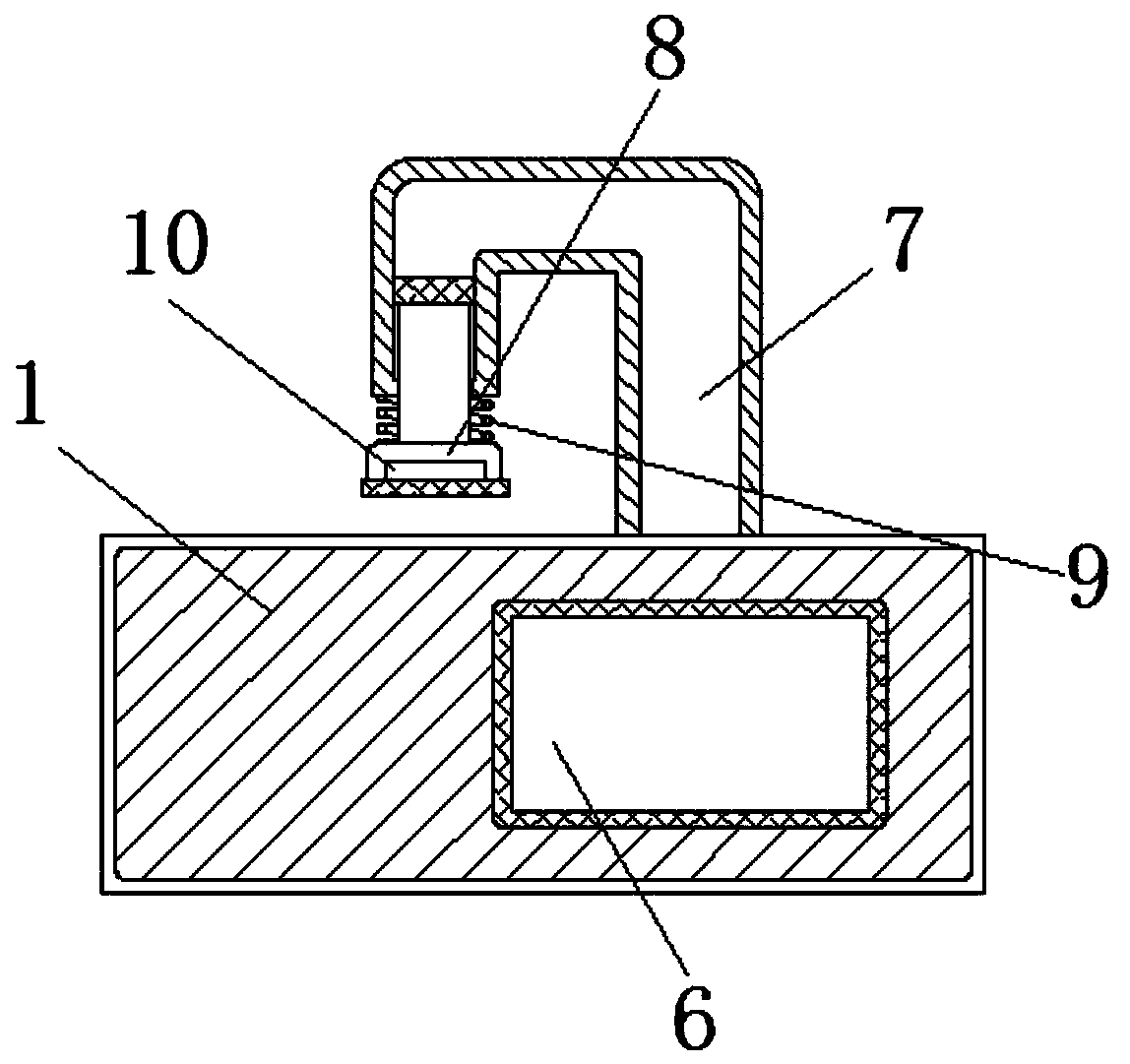

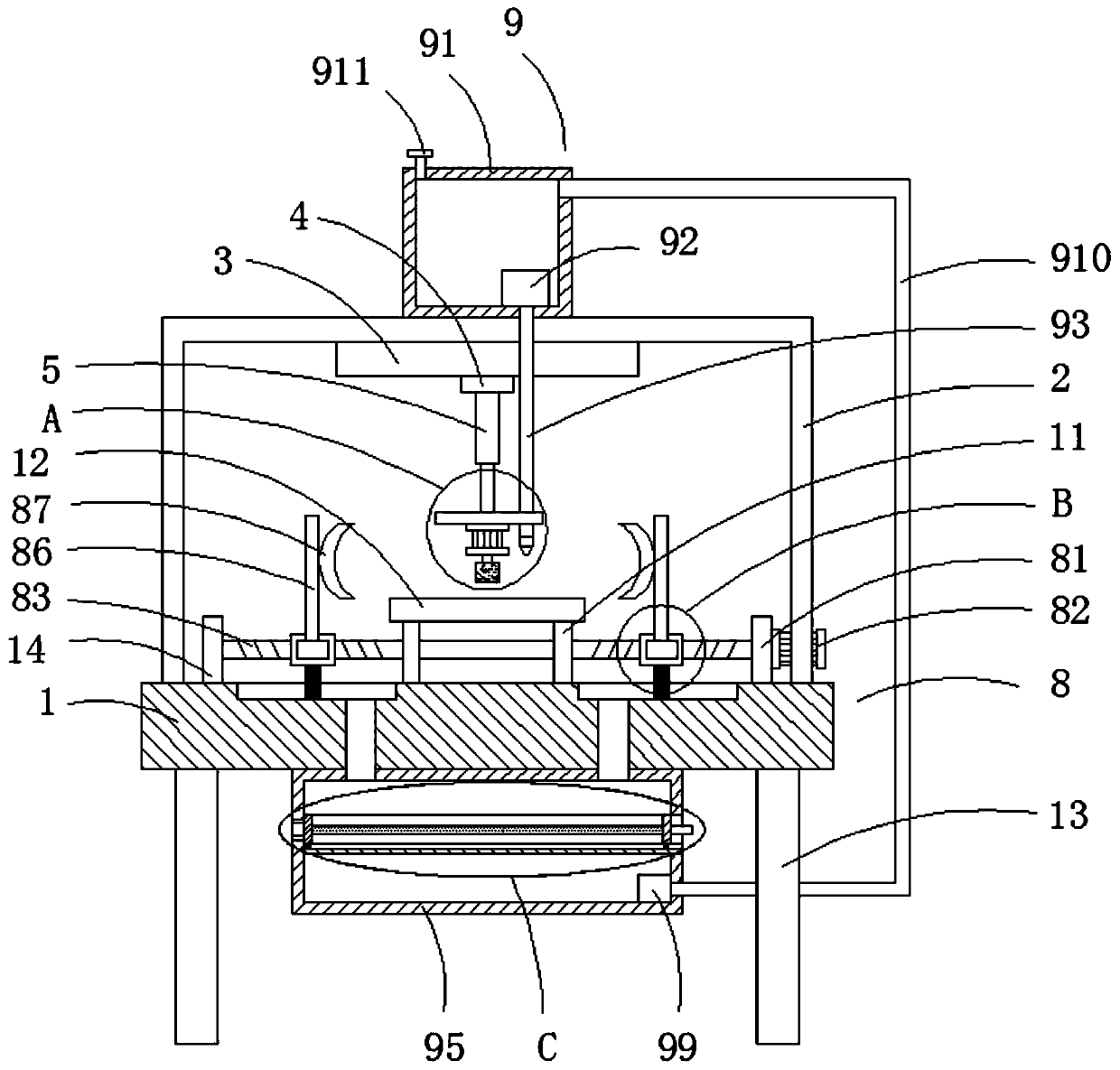

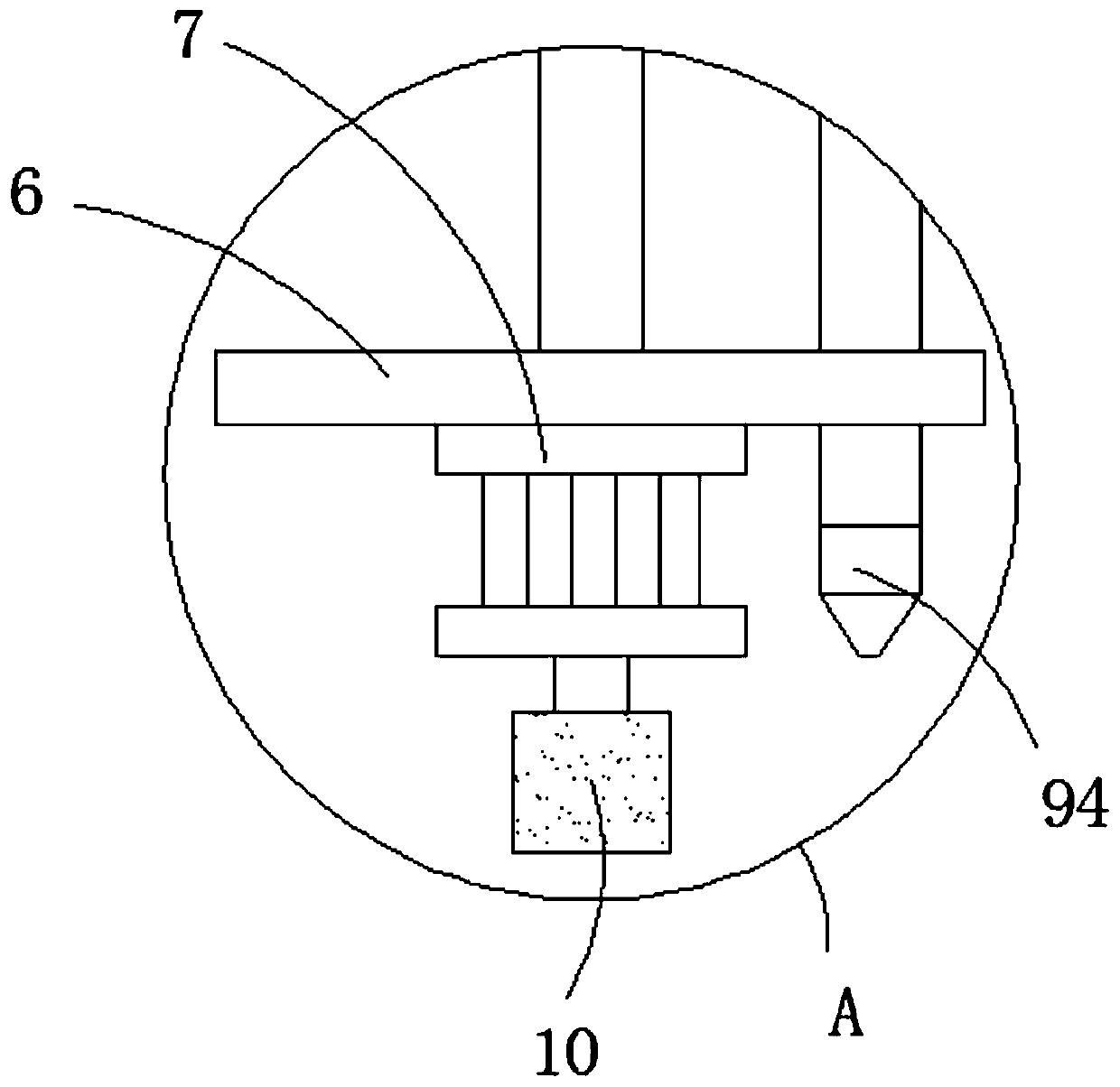

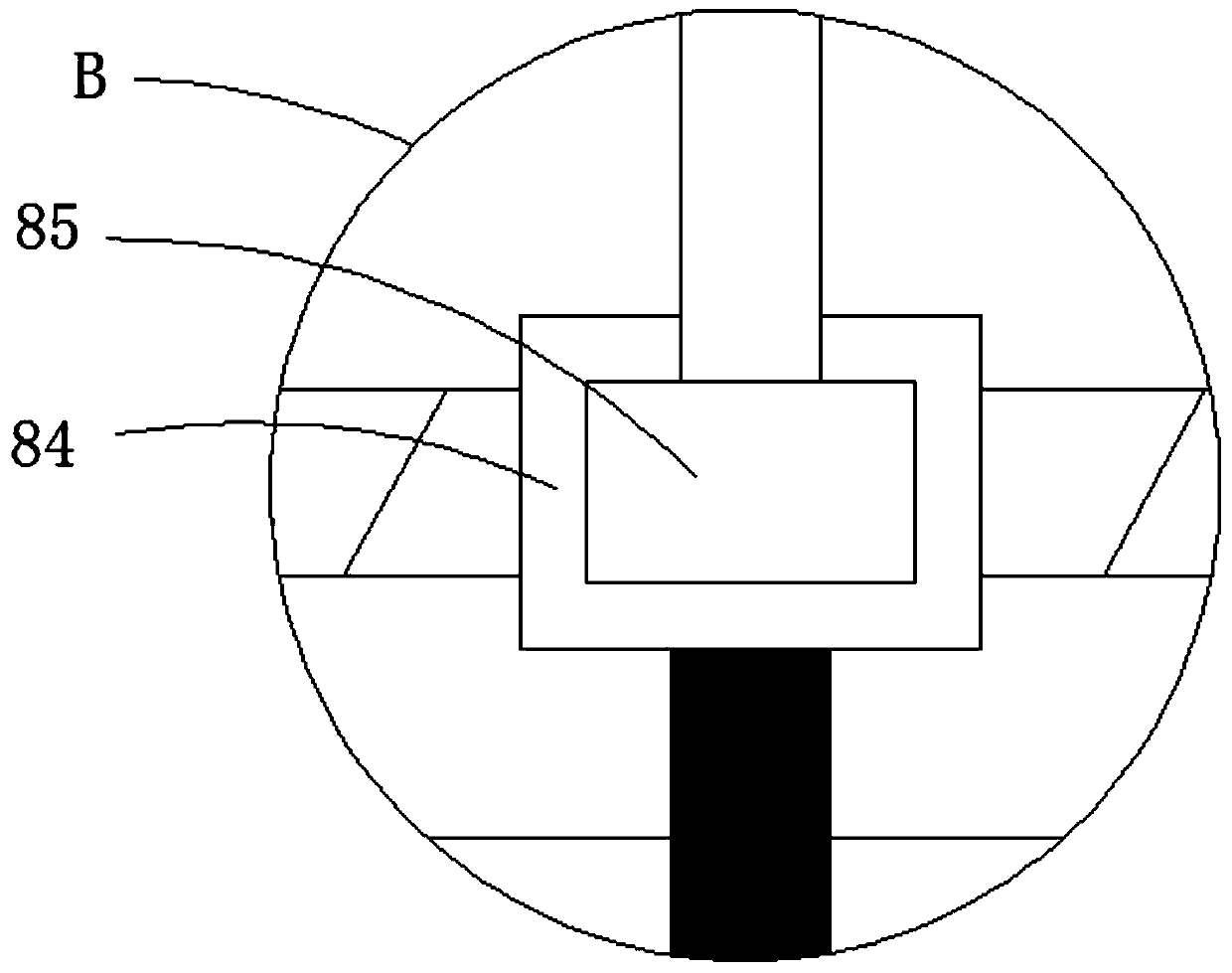

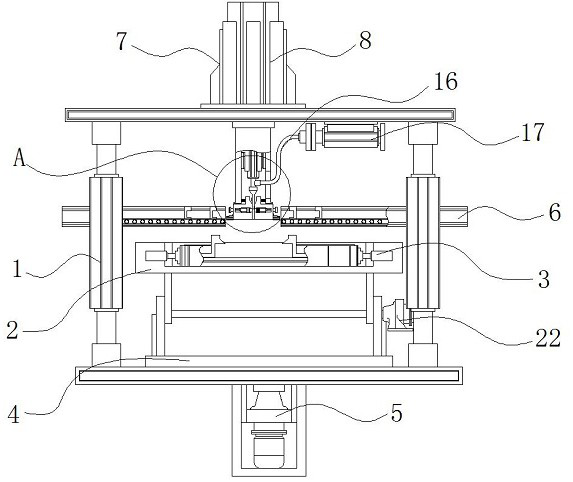

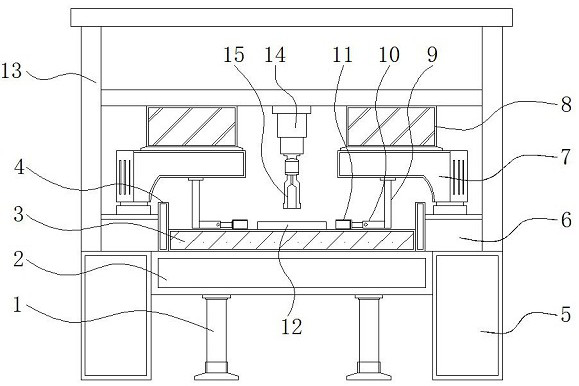

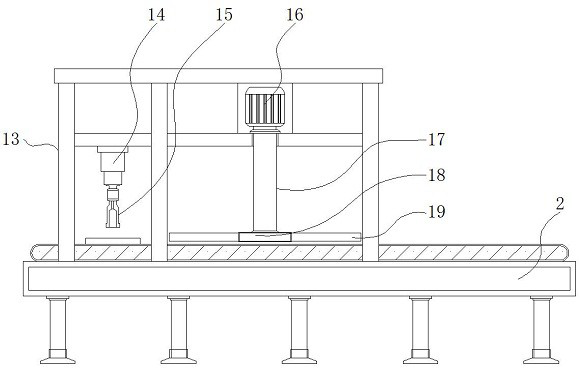

The invention discloses a drilling tool used for an aluminum alloy hub, and relates to the technical field of hub machining equipment. The drilling tool comprises a base. The upper end of the base isfixedly connected with a supporting mechanism with a collecting function. The upper end of the base is fixedly connected with a gantry support. The lower end of a horizontal part of the gantry supportis fixedly connected with two pneumatic mechanisms. The lower end of the horizontal part of the gantry support between the two pneumatic mechanisms is fixedly connected with a hydraulic cylinder. Thelower end of the hydraulic cylinder is fixedly connected with a lifting plate. The lower ends of the two pneumatic mechanisms are both fixedly connected with the upper end of the lifting plate. The lower end of the lifting plate is fixedly connected with a driving motor. The tail end of an output shaft of the driving motor is fixedly connected with a drill bit. The lower ends of the lifting plates at the left end and the right end of the driving motor are both fixedly connected with first elastic mechanisms. The lower ends of the two first elastic mechanisms are fixedly connected with the same protective cover. By means of the drilling tool, the hub can be positioned, the accuracy of drilling position is improved easily, in addition, cooling and impurity removing and collecting can be conducted on the drilled hub.

Owner:山东镁卡车轮有限公司

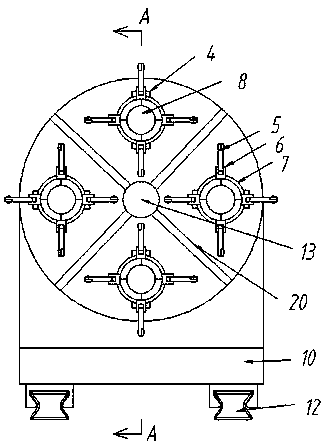

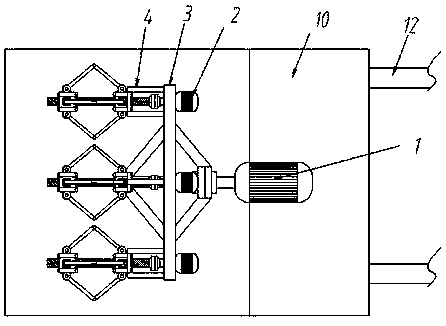

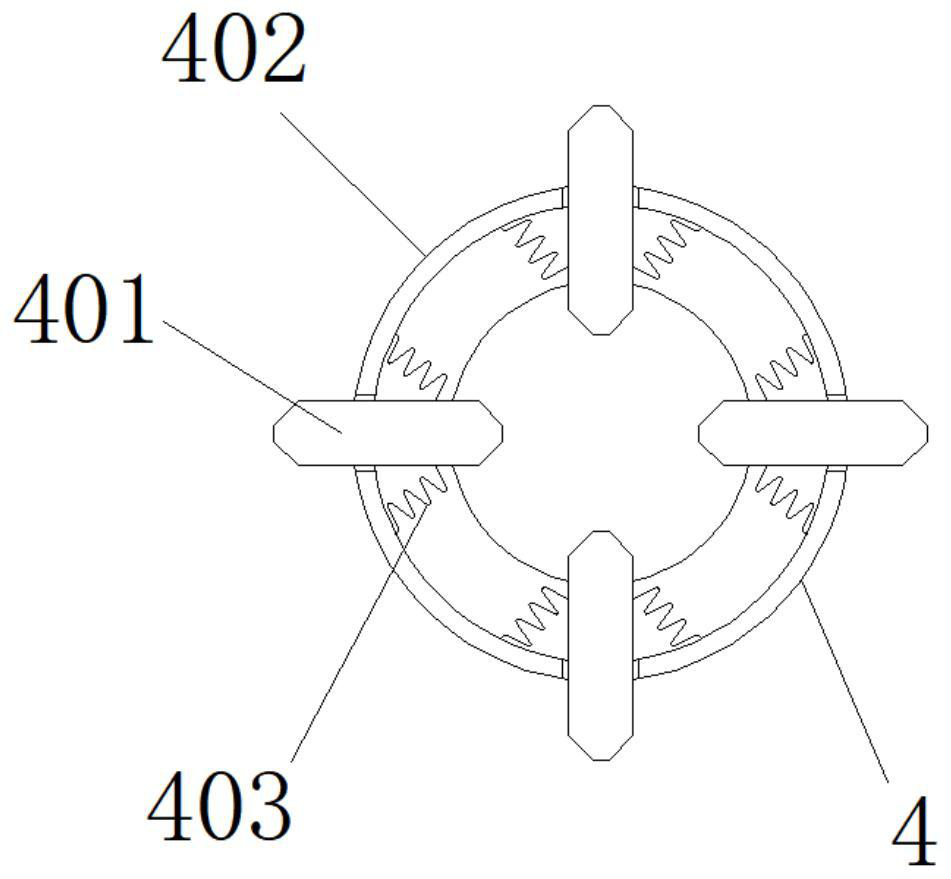

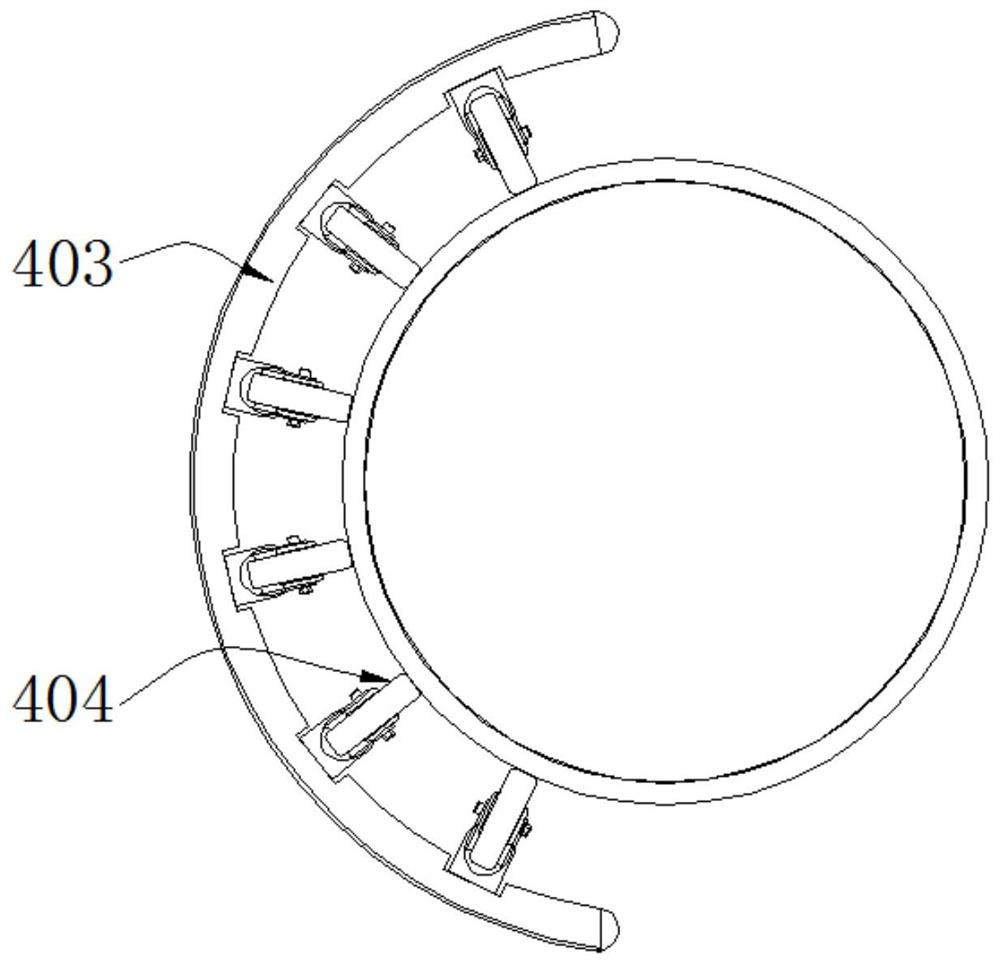

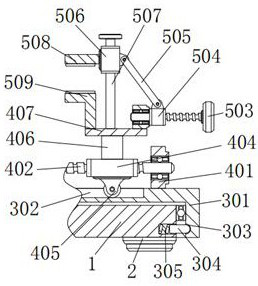

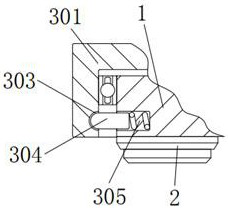

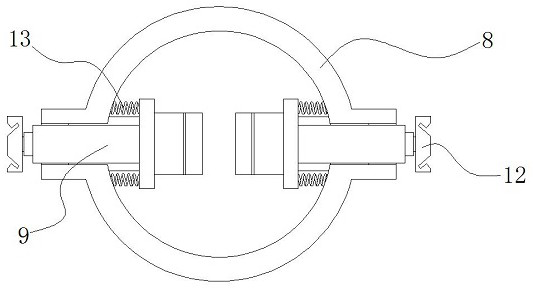

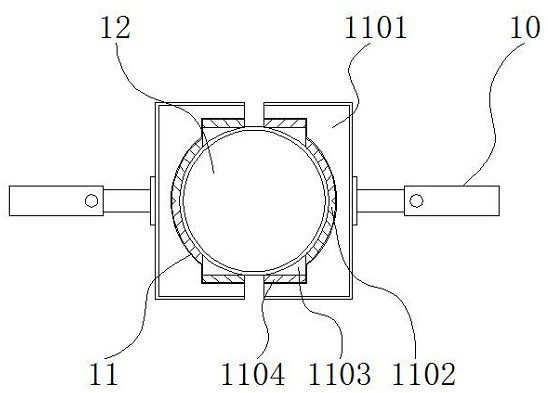

Clamping device for bearing ring cutting machining

PendingCN111113102AConvenient positioning and clampingGuaranteed uninterruptedMetal working apparatusPositioning apparatusCouplingClassical mechanics

The invention relates to the technical field of machining, in particular to a clamping device for bearing ring cutting machining. A first motor is fixed to a base, an output shaft of the first motor is connected with a main shaft through a coupler, the main shaft is fixedly sleeved with a supporting plate, a plurality of second motors are fixed to the back face of the supporting plate, an output shaft of each second motor is connected with a two-way screw through a coupler, threads of each two-way screw are oppositely arranged from the center point of the two-way screw to the two sides of thetwo-way screw, nuts are connected to the two oppositely-arranged threads in a threaded and screwed mode, ejector rods are fixedly hinged to the two nuts on the same two-way screw through hinge bases,the other ends of the two ejector rods are hinged through a shaft, and the nut close to one side of the supporting plate is fixedly connected with the supporting plate through a connecting rod. By means of the clamping device for bearing ring cutting machining, a bearing ring can be well positioned and clamped, the bearing ring can be installed and clamped while being cut, it is guaranteed that the cutting procedure is continuous, and the working efficiency is improved.

Owner:常州市大华环宇机械制造有限公司

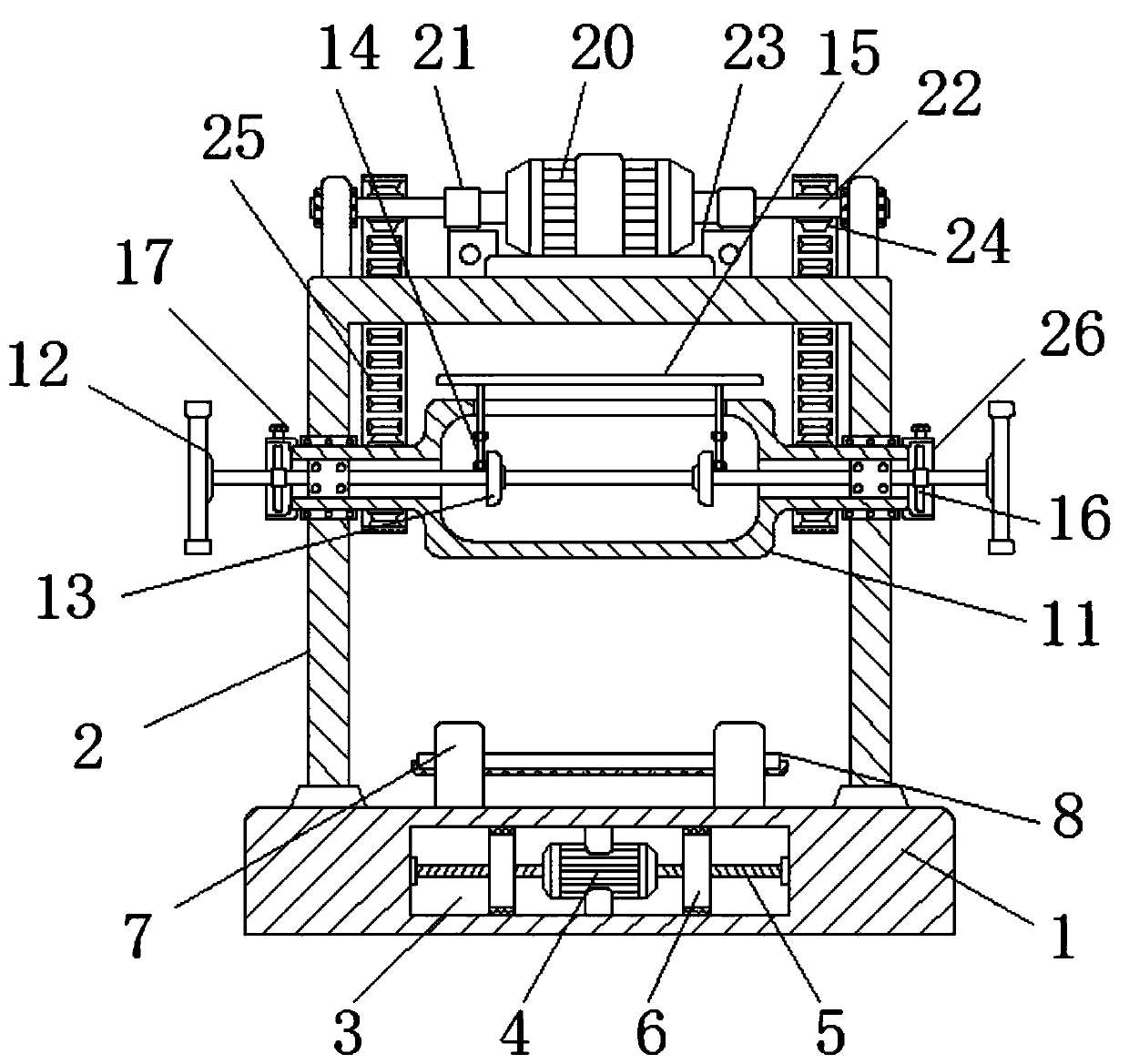

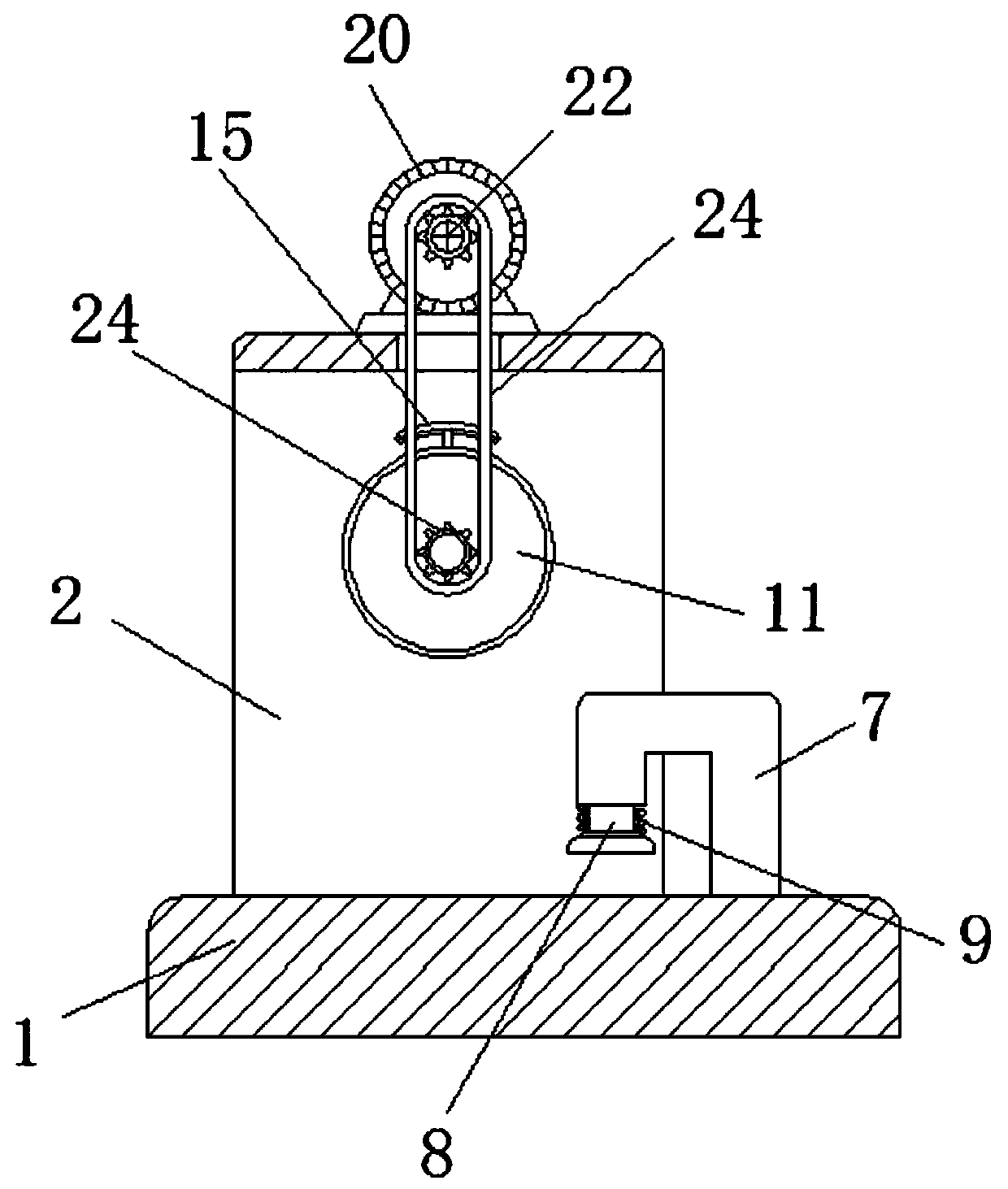

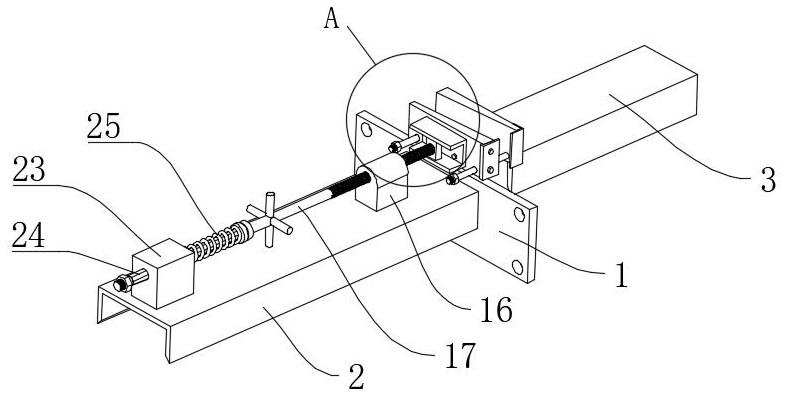

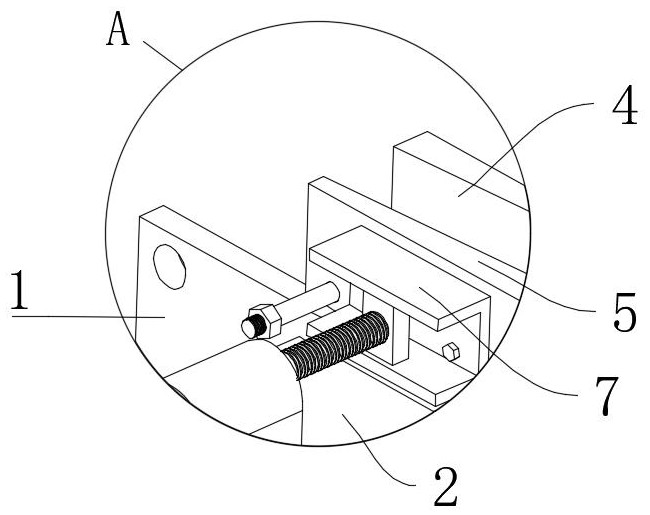

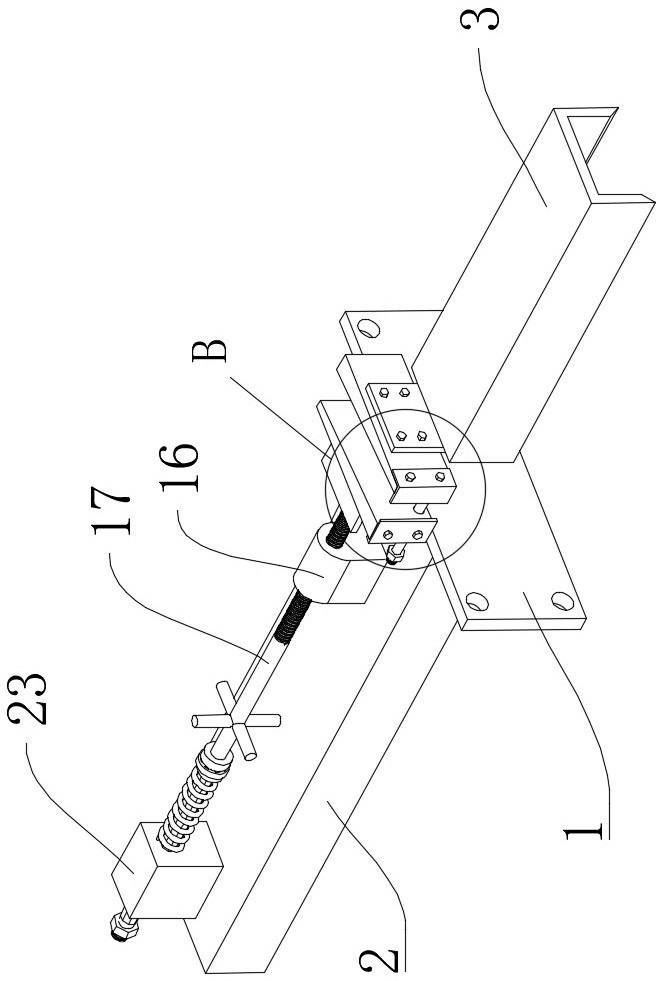

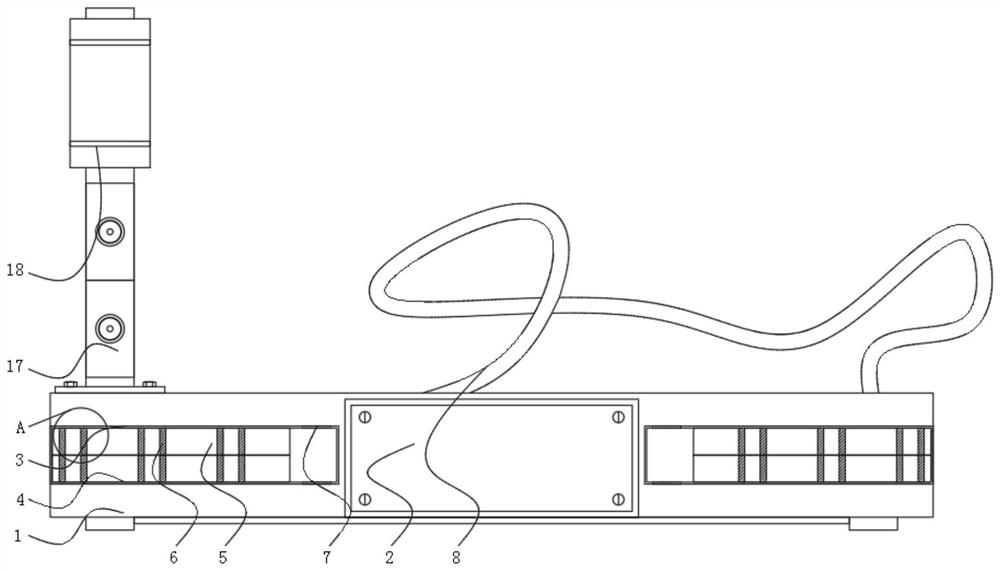

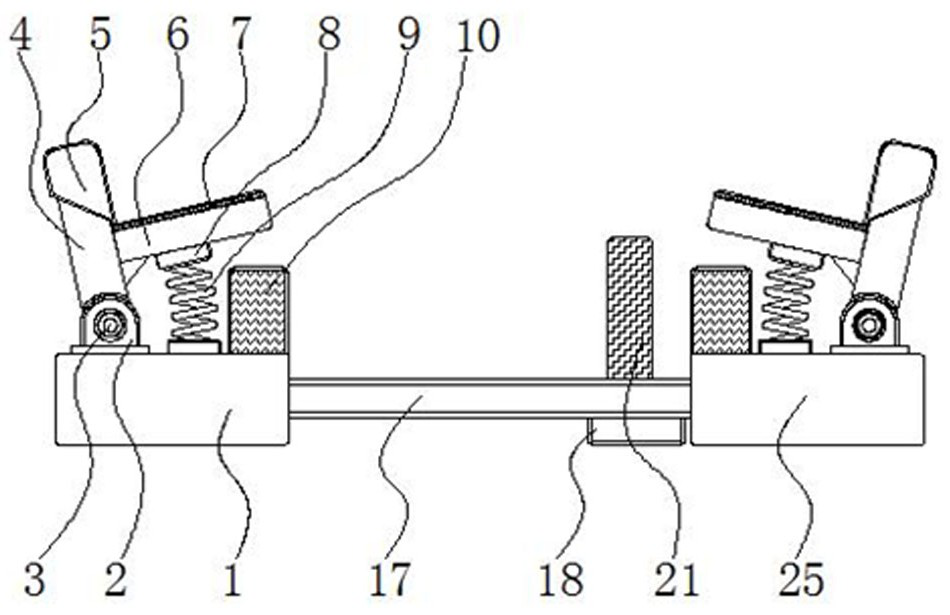

Tensile testing machine for detecting tensile strength of packaging bag

ActiveCN110672407AImprove positioning and clamping stabilityReduce overall sizeMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesRatchetElectric machinery

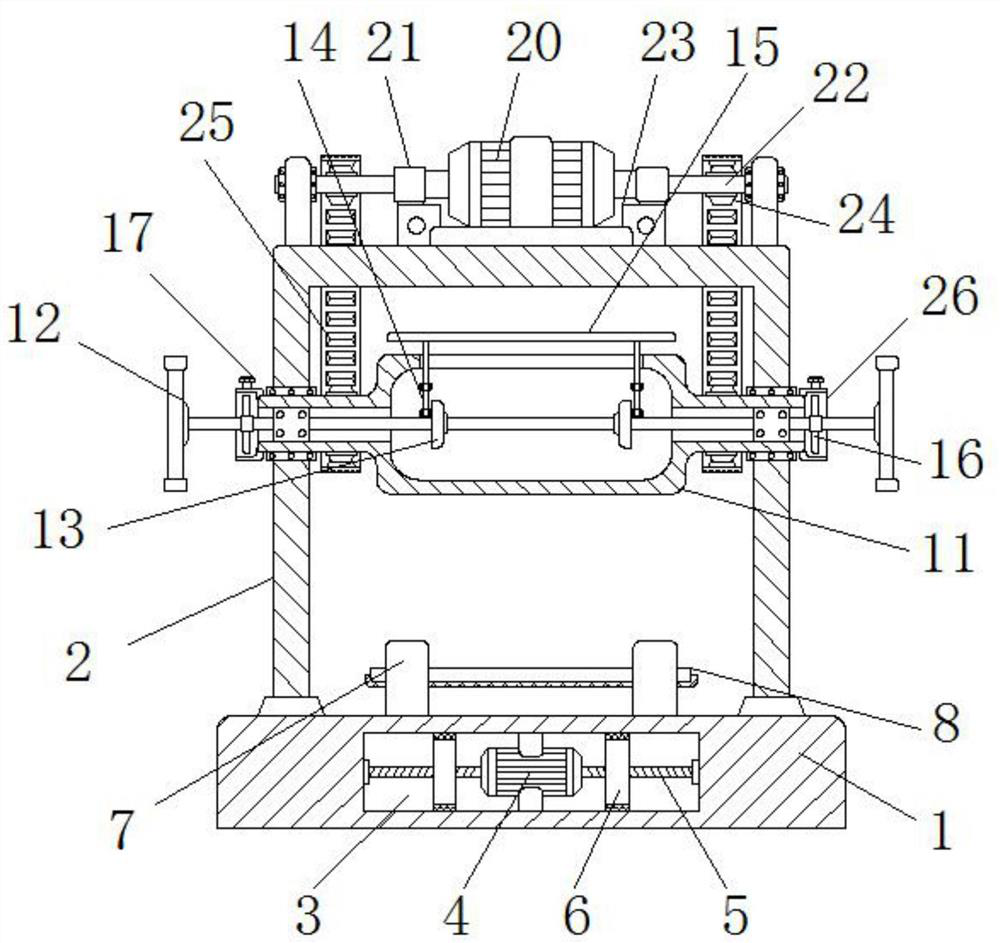

The invention discloses a tensile testing machine for detecting the tensile strength of a packaging bag. The tensile testing machine for detecting the tensile strength of the packaging bag comprises abase, a first motor, a pressure sensor, a second motor and a torque sensor. A bracket is fixedly connected to the top of the base, and a liquid groove is formed in the base. A screw rod is coaxiallyconnected to the end of an output shaft of the first motor, a positioning tube is fixedly connected to the top of the base, and a positioning member is arranged at the end of the positioning tube. A rotating roller is arranged on the bracket, a positioning disk is fixed to the end of the rotating roller, and a ratchet is arranged on the outer wall of a rotating rod in the positioning disk. The second motor is fixedly installed at the center of the top of the bracket, and the end of an output shaft of the second motor is fixedly connected with one end of a cross rod through a coupler. Accordingto the tensile testing machine for detecting the tensile strength of the packaging bag, two sides of the packaging bag can be conveniently positioned and clamped, the positioning and clamping stability of the packaging bag is improved, and rotating type tensile strength detection reduces the overall size of the device.

Owner:商丘市锦华包装科技有限公司

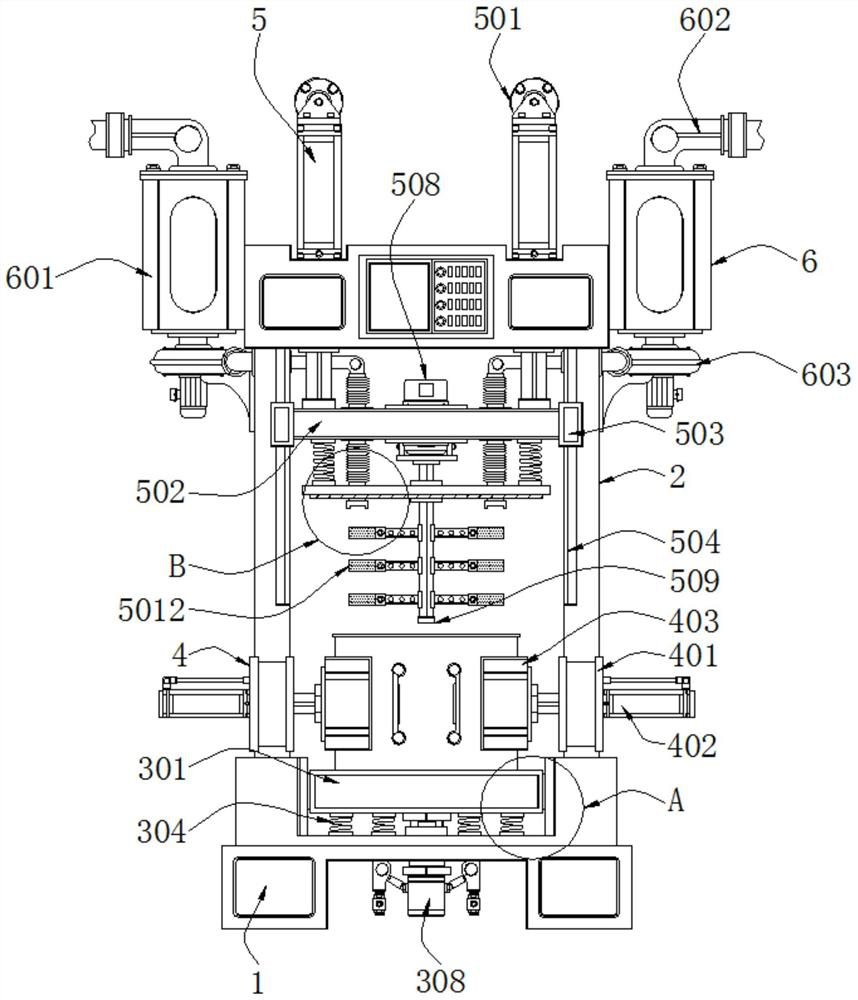

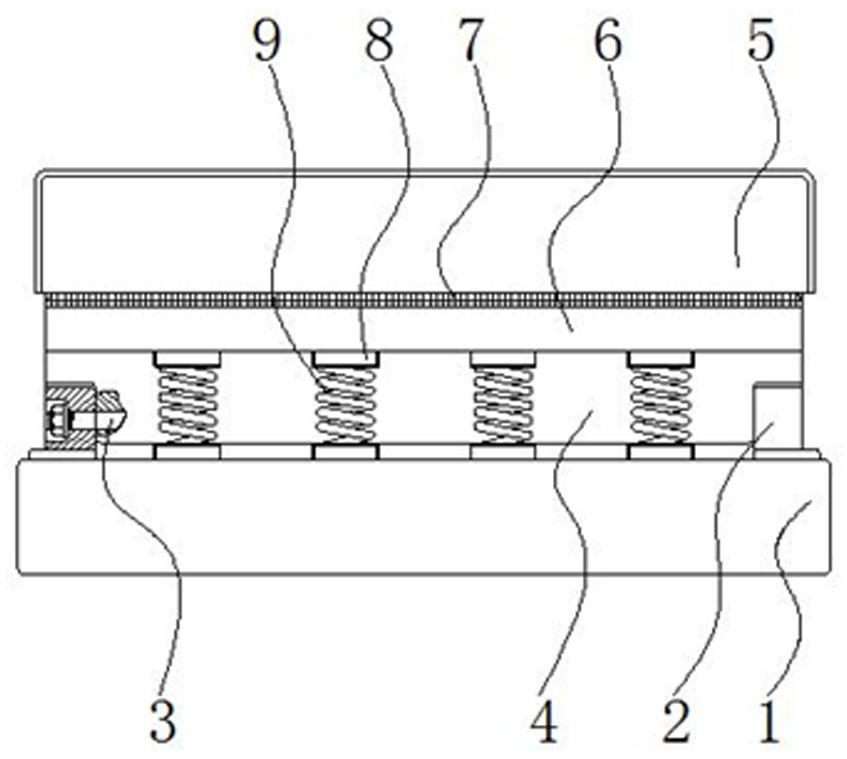

High-efficiency pretreatment device for motor shell inner side surface rough machining

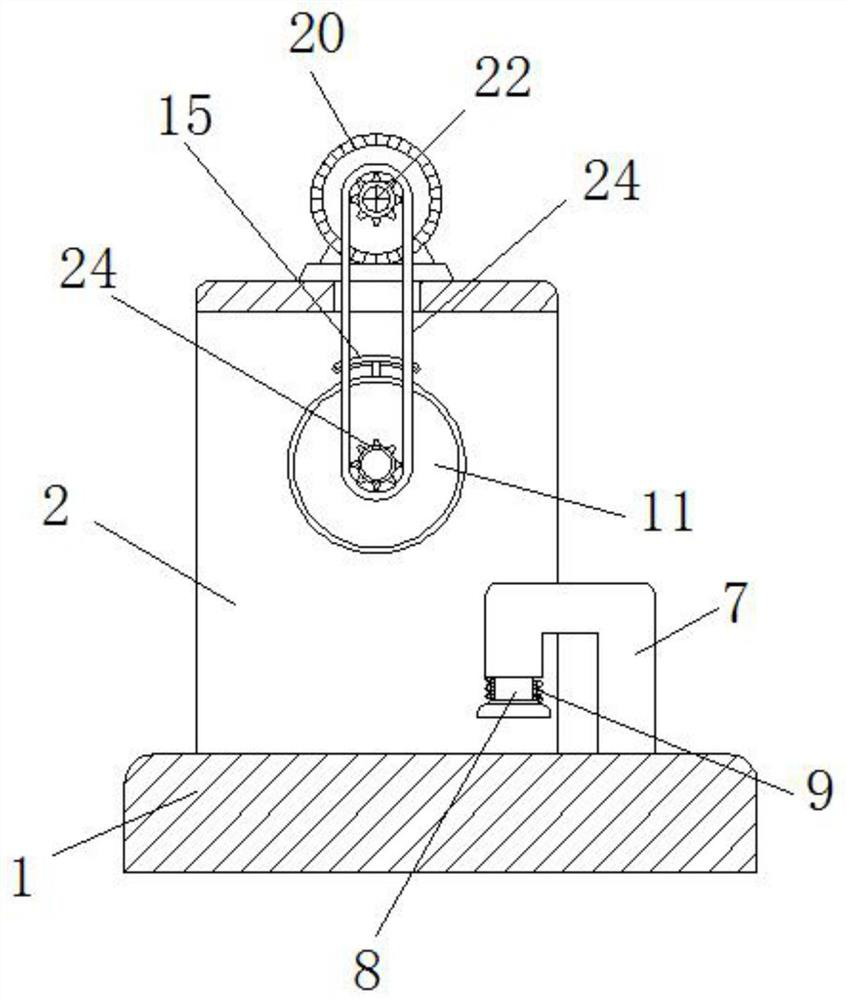

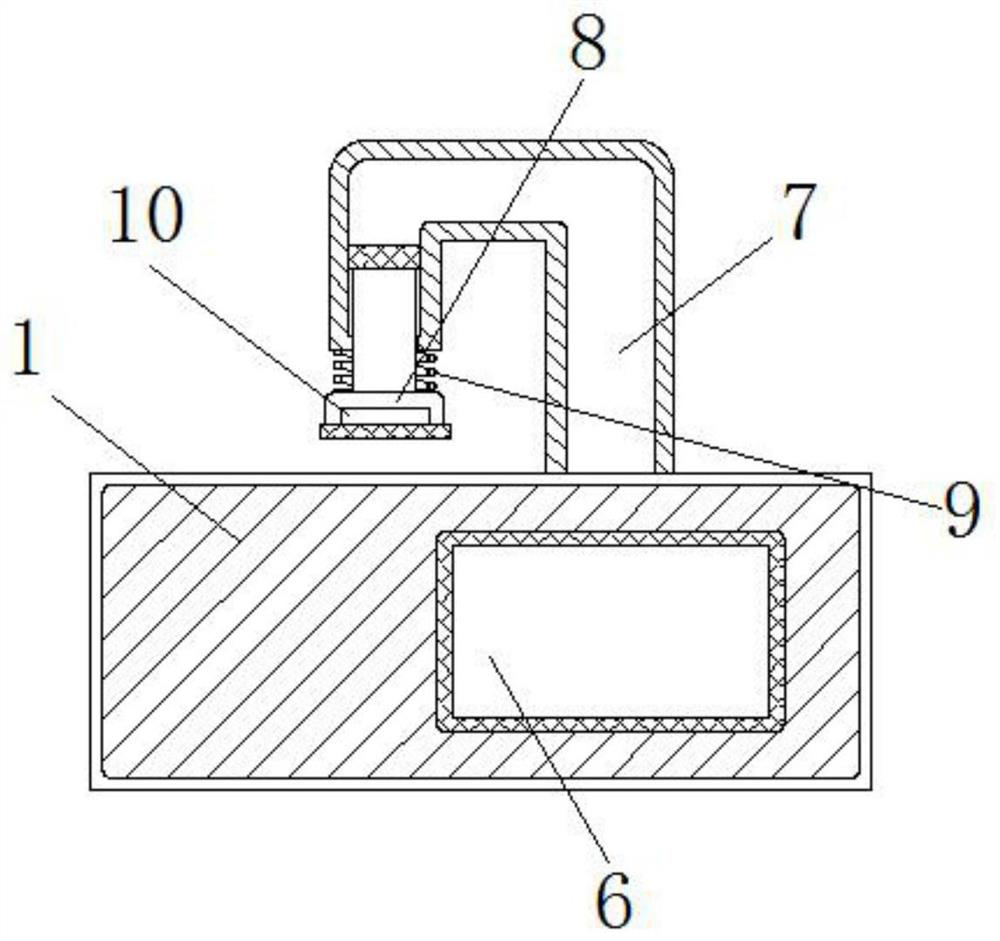

ActiveCN110539222AConvenient positioning and clampingImprove processing efficiencyEdge grinding machinesPolishing machinesPre treatmentMachining

The invention relates to the technical field of motor shell machining devices, and discloses a high-efficiency pretreatment device for motor shell inner side surface rough machining. The device comprises a worktable, a machine frame is fixedly connected with the upper surface of the worktable, an electric slide rail is fixedly connected with the inner wall of the top of the machine frame, the bottom of the electric slide rail is slidably connected with a movable block, the bottom of the movable block is fixedly connected with an electric push rod, the bottom of the electric push rod is fixedlyconnected with a support plate, the bottom of the support plate is fixedly connected with a first rotary motor, the output end of the first rotary motor is fixedly connected with a polishing pad, theupper surface of the worktable is fixedly connected with a clamping mechanism, and the top of the machine frame is fixedly connected with a debris cleaning mechanism. According to the high-efficiencypretreatment device for motor shell inner side surface rough machining, a motor shell can be conveniently positioned and clamped, the machining efficiency of the motor shell is improved, meanwhile, debris generated during polishing can be conveniently cleaned, and the debris can be conveniently collected.

Owner:马鞍山常裕机械设备股份有限公司

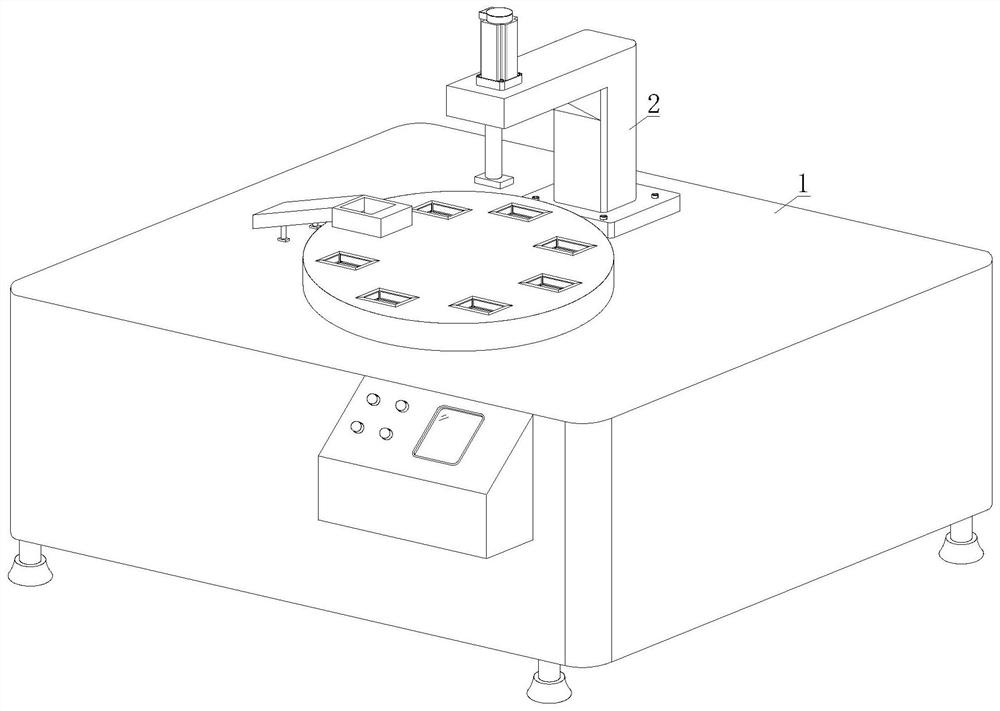

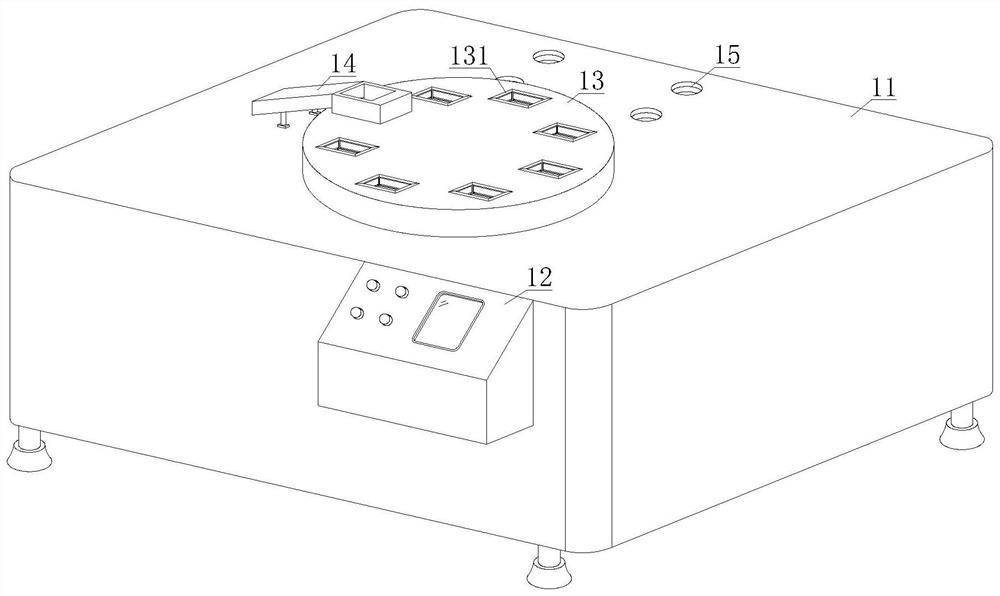

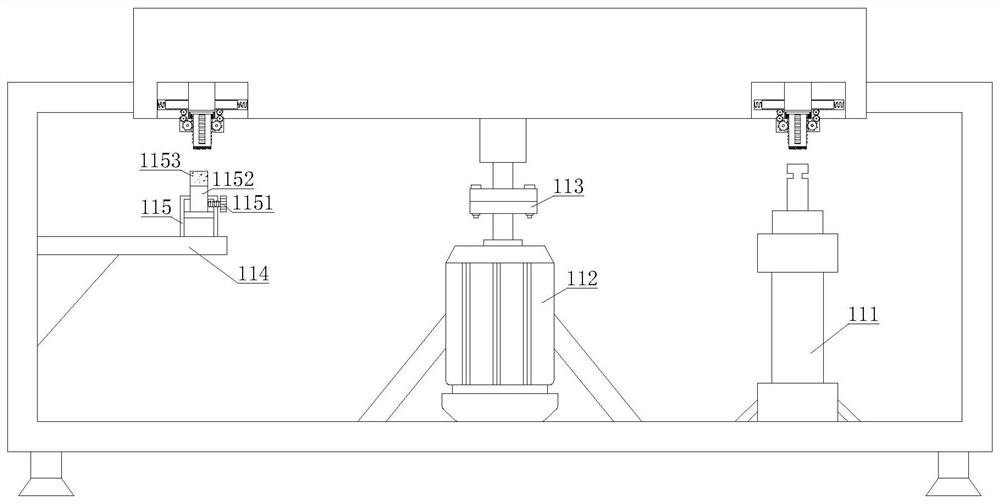

Anisotropic magnetoresistive head assembling equipment and implementation method thereof

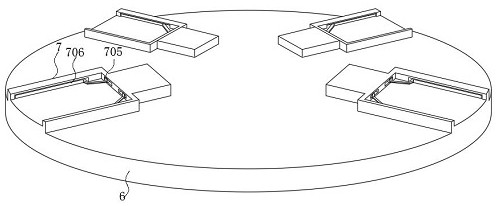

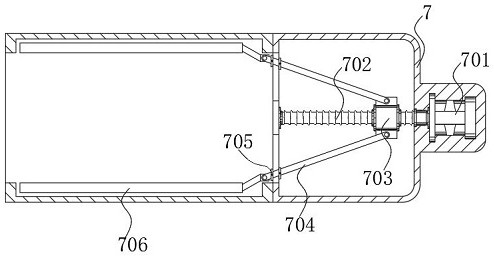

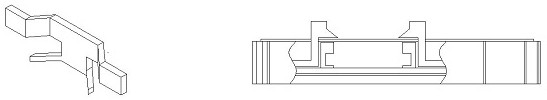

InactiveCN112077574AEasy to pressTo achieve the effect of fixed positioningManufacture of flux-sensitive headsMounting head within housingGear wheelMagnetic reluctance

The invention discloses anisotropic magnetoresistive head assembling equipment. The equipment comprises an operation table and a press-in device; the press-in device is installed at one side of the upper end of the operation table in a threaded mode; when a second air cylinder continuously descends for clamping, a push plate compresses a second spring to retract under the pushing force of clamping, and therefore material assembling is prevented from being damaged due to the fact that the clamping force of first push rods is too large; and after the second air cylinder ascends, a telescopic push rod ascends together, so that the first push rods are driven by a third-level gear to retract, the push plate automatically stretches out under the elastic force reset of the second spring, and therefore next-time positioning and clamping are facilitated. Meanwhile, the invention further discloses an implementation method of the anisotropic magnetoresistive head assembling equipment; a servo motor rotates to drive a rotary disc to rotate; when the rotary disc rotates; a sliding groove at the lower end of the telescopic push rod is in sliding connection with the second air cylinder; and aftera material loading groove rotates to the lower end of a pressing rod, the two pairs of first push rods extend out at the same time to fixedly clamp materials, so that the positioning and the fixing effects are achieved, and the pressing rod can press materials conveniently.

Owner:全南群英达电子有限公司

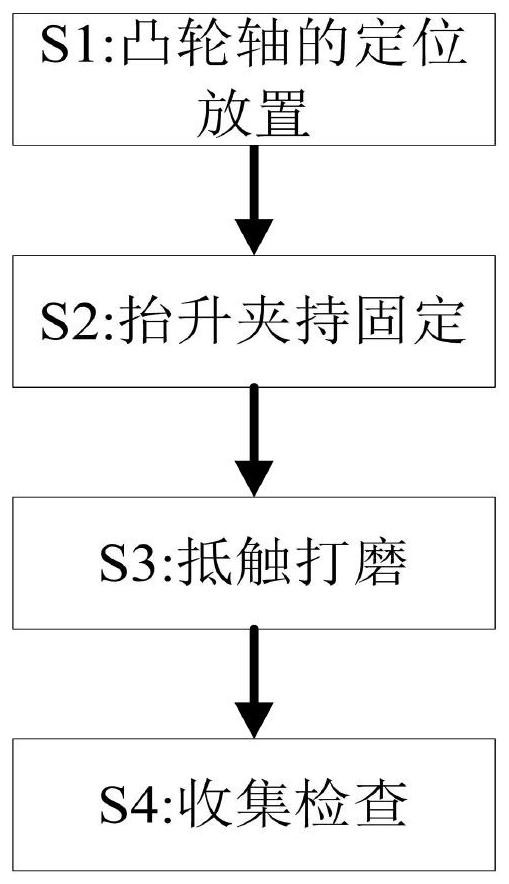

Engine camshaft manufacturing and machining process

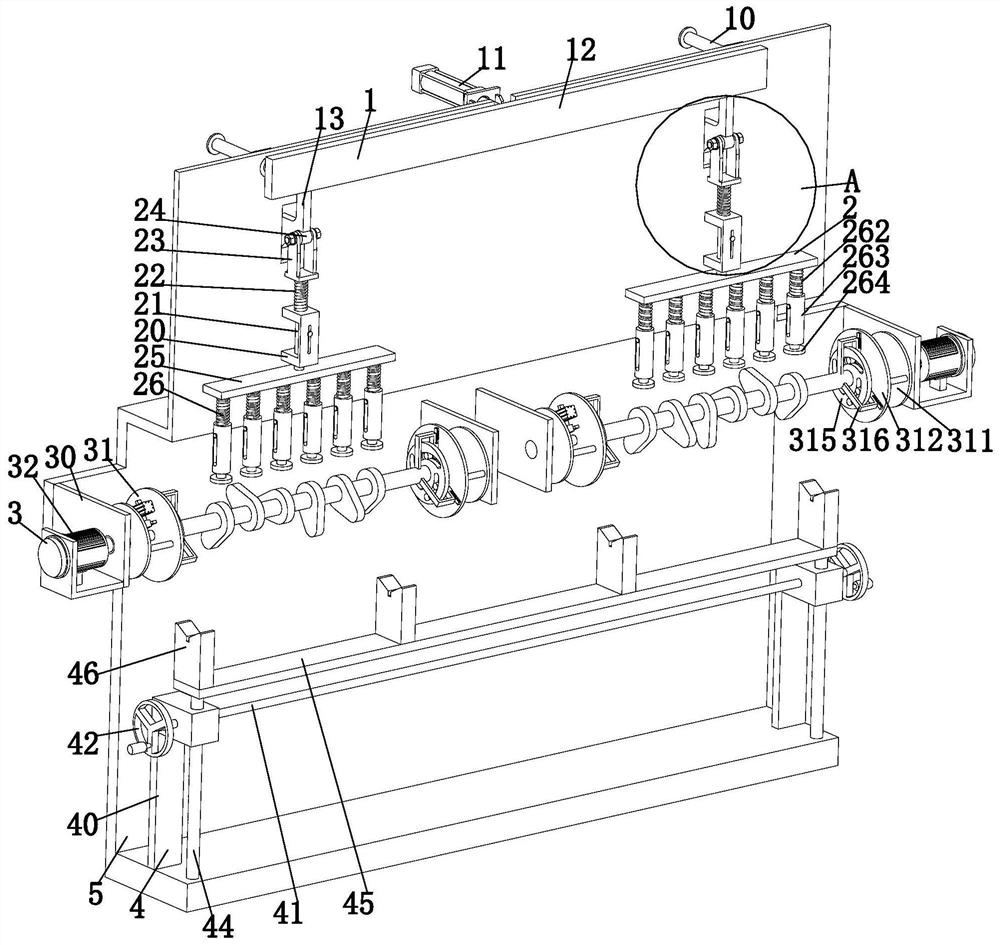

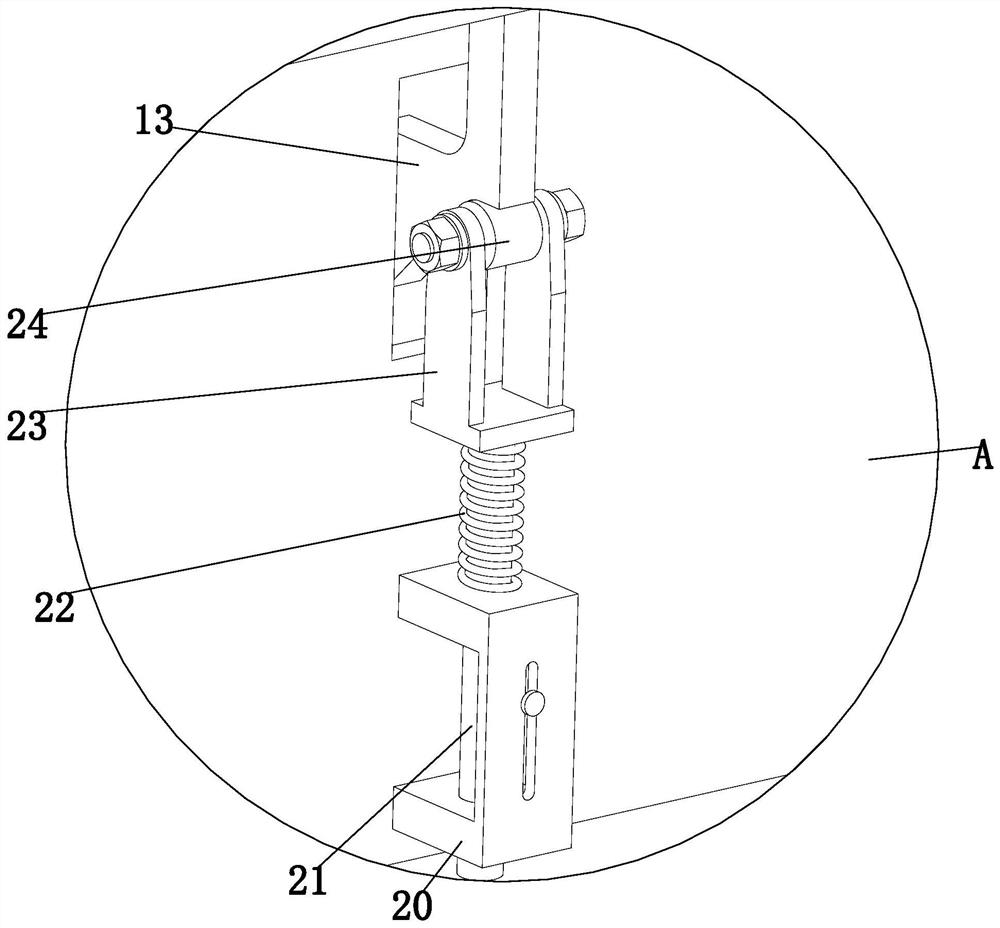

InactiveCN112476068ATimely replacementEfficient removalGrinding carriagesGrinding drivesMachining processCamshaft

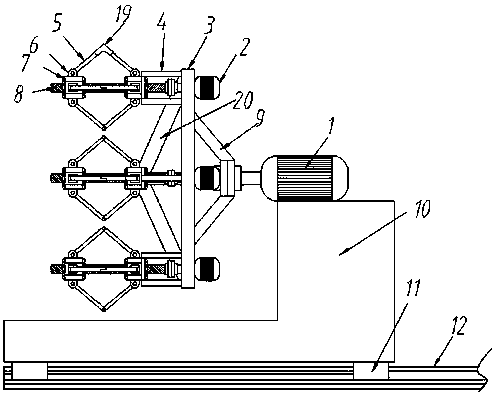

The invention provides an engine camshaft manufacturing and machining process which comprises pushing mechanisms, polishing mechanisms, clamping mechanisms, lifting mechanisms and a main beam verticalplate frame. The pushing mechanisms are installed on the main beam vertical plate frame, the polishing mechanisms are arranged under the pushing mechanisms, and the polishing mechanisms are symmetrically installed on the outer wall of the main beam vertical plate frame; and the polishing mechanisms are connected with the pushing mechanisms in a rolling manner, the clamping mechanisms are arrangedunder the polishing mechanisms and symmetrically installed on the outer wall of the main beam vertical plate frame, and the lifting mechanisms are arranged under the clamping mechanisms and installedon the bottom end face of the main beam vertical plate frame. According to the engine camshaft manufacturing and machining process, the problems of high operation difficulty, low polishing efficiency, low polishing precision, easy generation of burrs, incapability of normal operation of the whole mechanical system due to existence of the burrs, reduced reliability and stability, influence on product quality and the like caused by polishing by adopting a manual manner in general factories are solved.

Owner:杭州佳顿智能科技有限公司

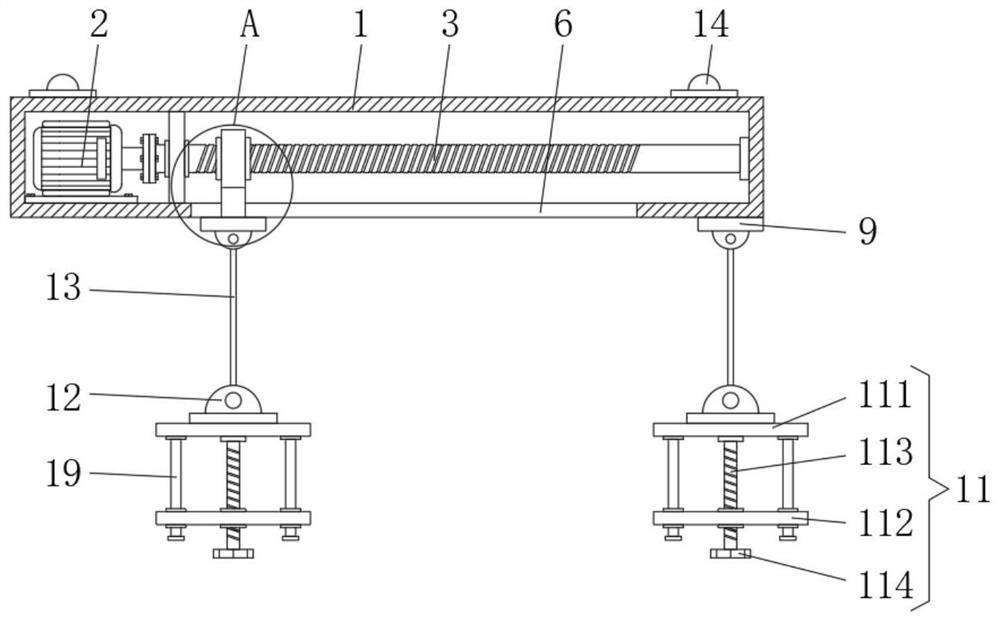

Fast and accurate hoisting device and method for prefabricated stairs

PendingCN113562632AConvenient positioning and clampingQuick liftLoad-engaging elementsCranesControl engineeringServo

The invention relates to the technical field of building construction equipment, in particular to a fast and accurate hoisting device and method for prefabricated stairs. The fast and accurate hoisting device comprises a box body, wherein a servo motor is bolted to an inner cavity of the box body; a partition plate is arranged at the right side of the servo motor; and a rotating shaft is bolted to an output shaft of the servo motor, the rotating shaft penetrates to the right side of the partition plate, and the rotating shaft is rotationally connected with the inner wall of the box body through a bearing seat; Through the specific structure design, the device is simple in structure and easy to manufacture, has the advantages of being capable of conveniently positioning and clamping the prefabricated stairs, suitable for the prefabricated stairs of different models, balanced and stable in the hoisting process, rapid to install and the like, and the problems that existing prefabricated stairs are high in installation accuracy requirement, however, on-site installation of the prefabricated stairs is relatively difficult, and the prefabricated stairs cannot be accurately positioned and fixed are solved, therefore, the hoisting work efficiency of the prefabricated stairs can be remarkably improved.

Owner:CHINA MCC17 GRP

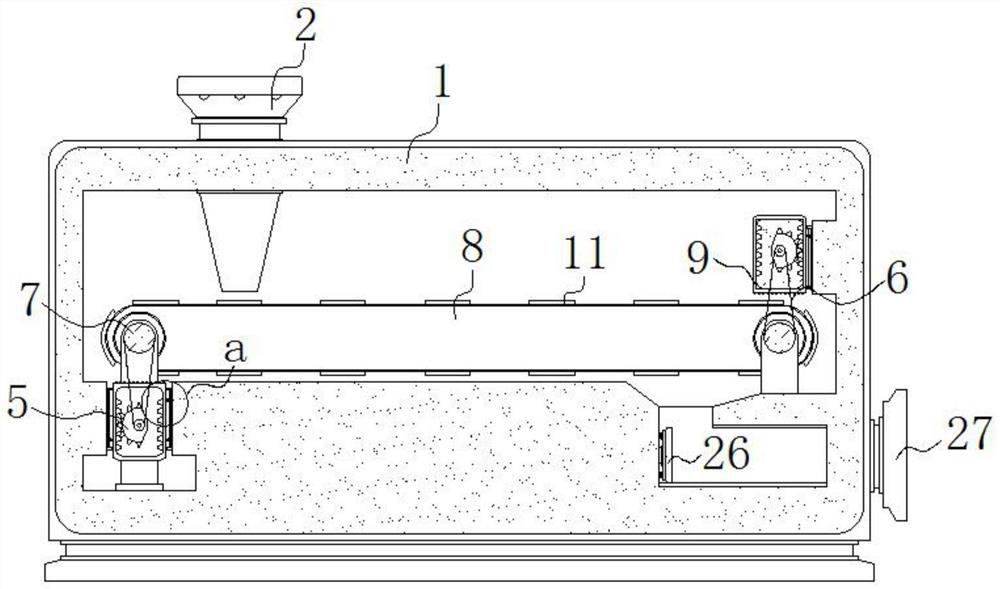

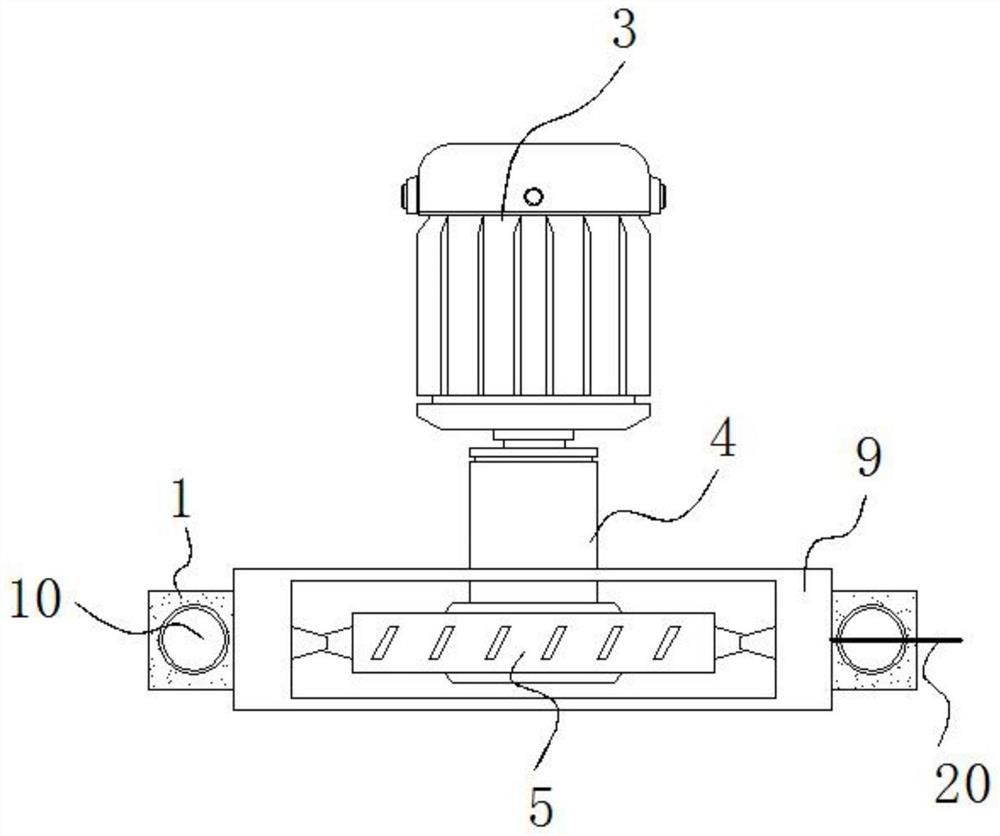

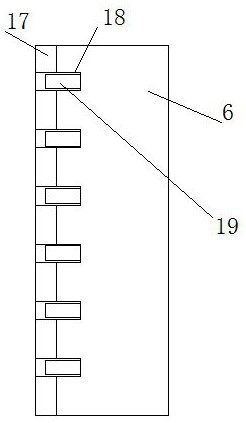

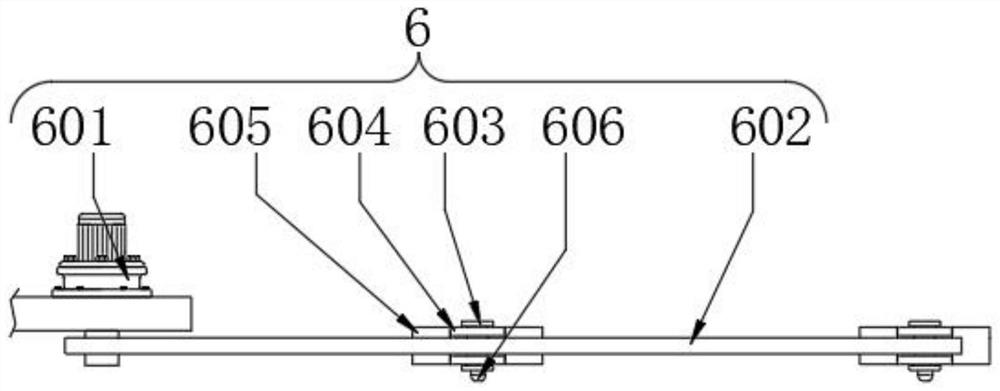

Fixed-distance conveying device for bolt machining

InactiveCN114537977AMove back and forth steadilyConvenient positioning and clampingConveyorsConveyor partsGear wheelTransmission belt

The invention discloses a fixed-distance conveying device for bolt machining. The fixed-distance conveying device comprises a protection box, a feeding opening, a fixed motor, a falling-off mechanism, a conveying belt body and a discharging opening. A discharging opening is formed in the lower position of the right side of the protection box; the output end of the fixed motor is connected with a rotating rod, the outer side of the middle position of the rotating rod is connected with the shaft end of the conveying belt body through a conveying belt, the outer side of the rotating rod is sleeved with a sector gear in an embedded mode, and the sector gear is arranged in a connecting block; a plurality of sets of fixing blocks are distributed at the top of the conveying belt body at equal intervals, and fixing gears are arranged on the rear sides of the fixing blocks. According to the fixed-distance conveying device for bolt machining, the fixed motor is arranged, by starting the fixed motor, a connecting block can stably move back and forth in the protection box through a guide rod, and the outer side of the connecting block can make contact with a fixed gear arranged on the outer side of a fixed block.

Owner:南京蓝尔图革科技有限公司

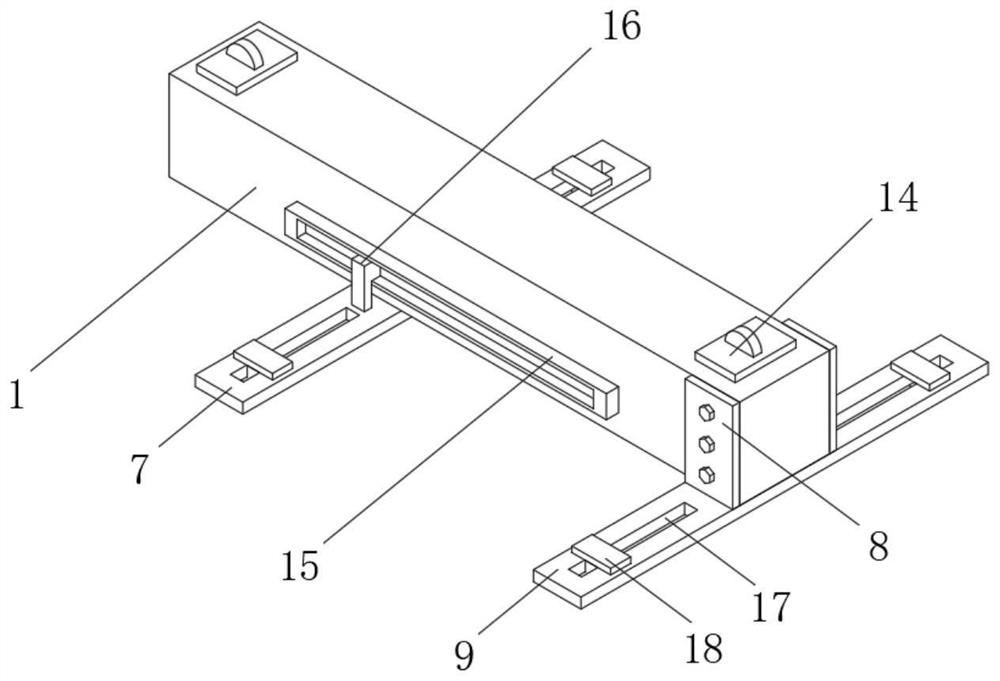

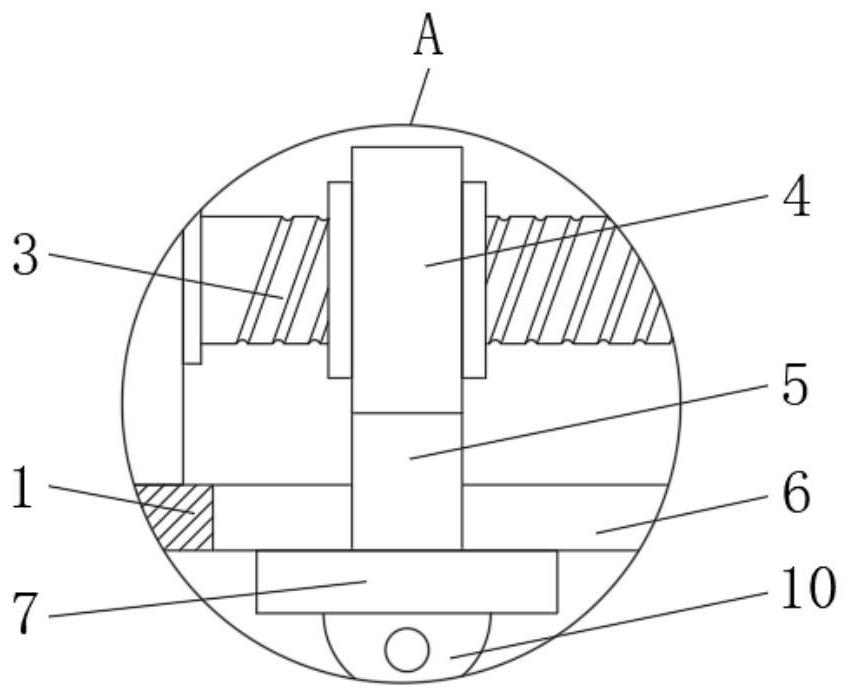

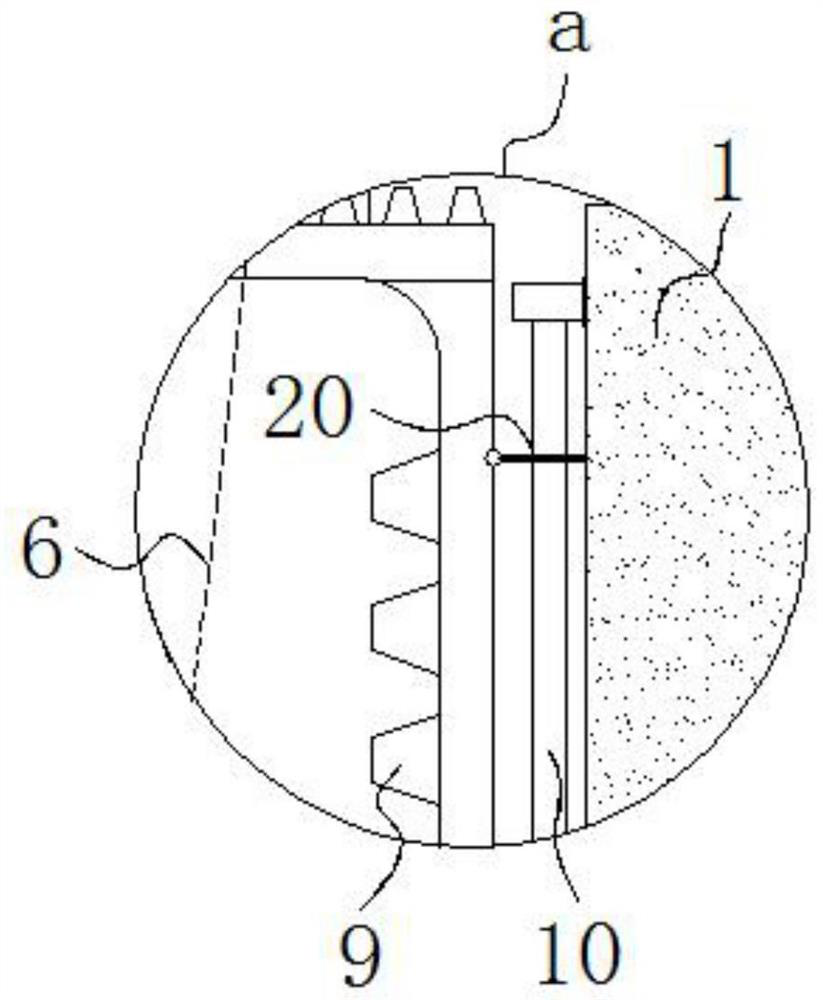

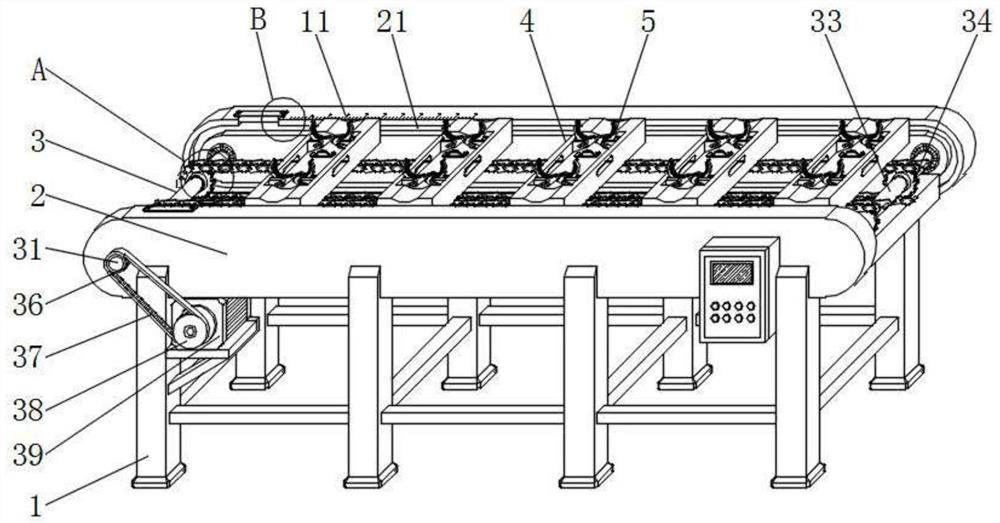

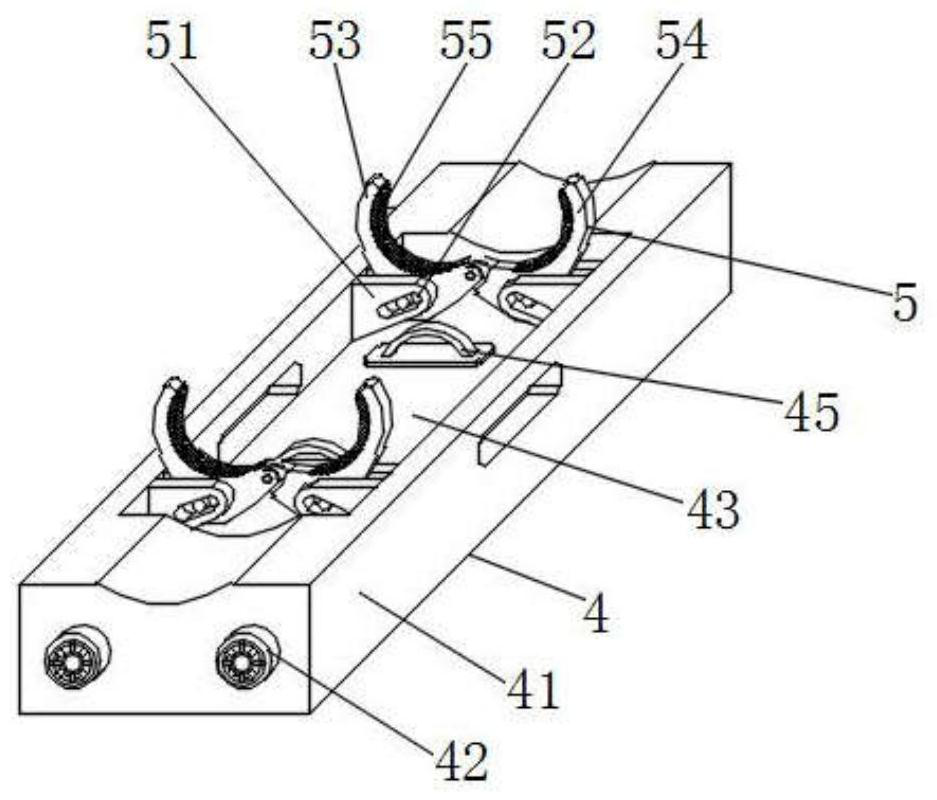

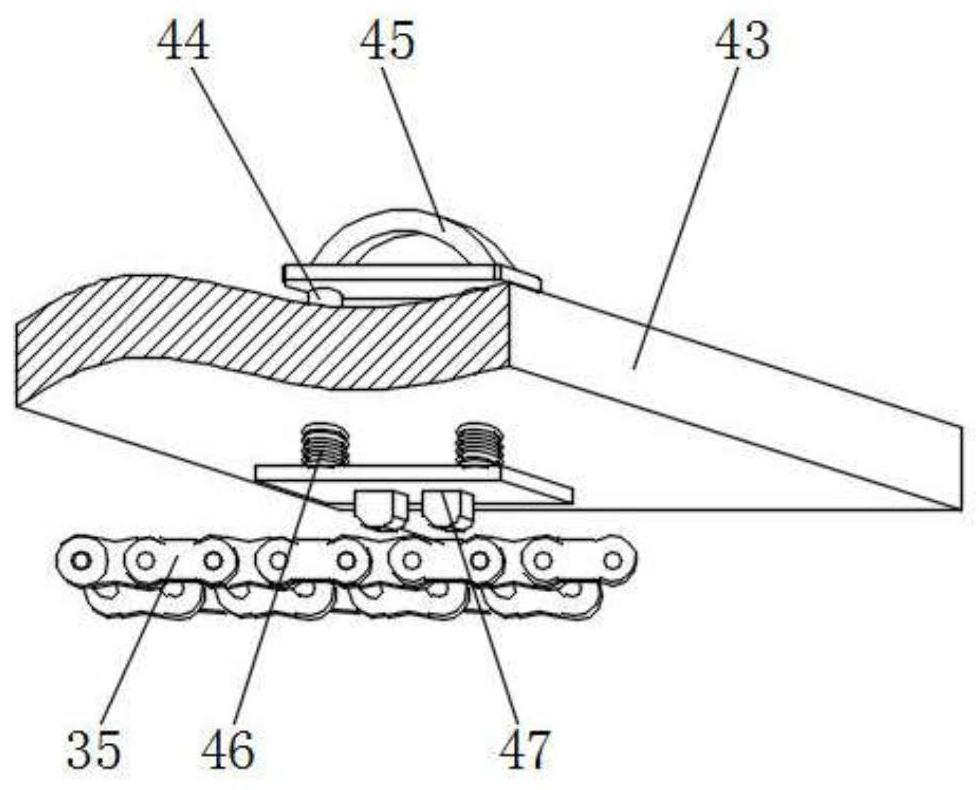

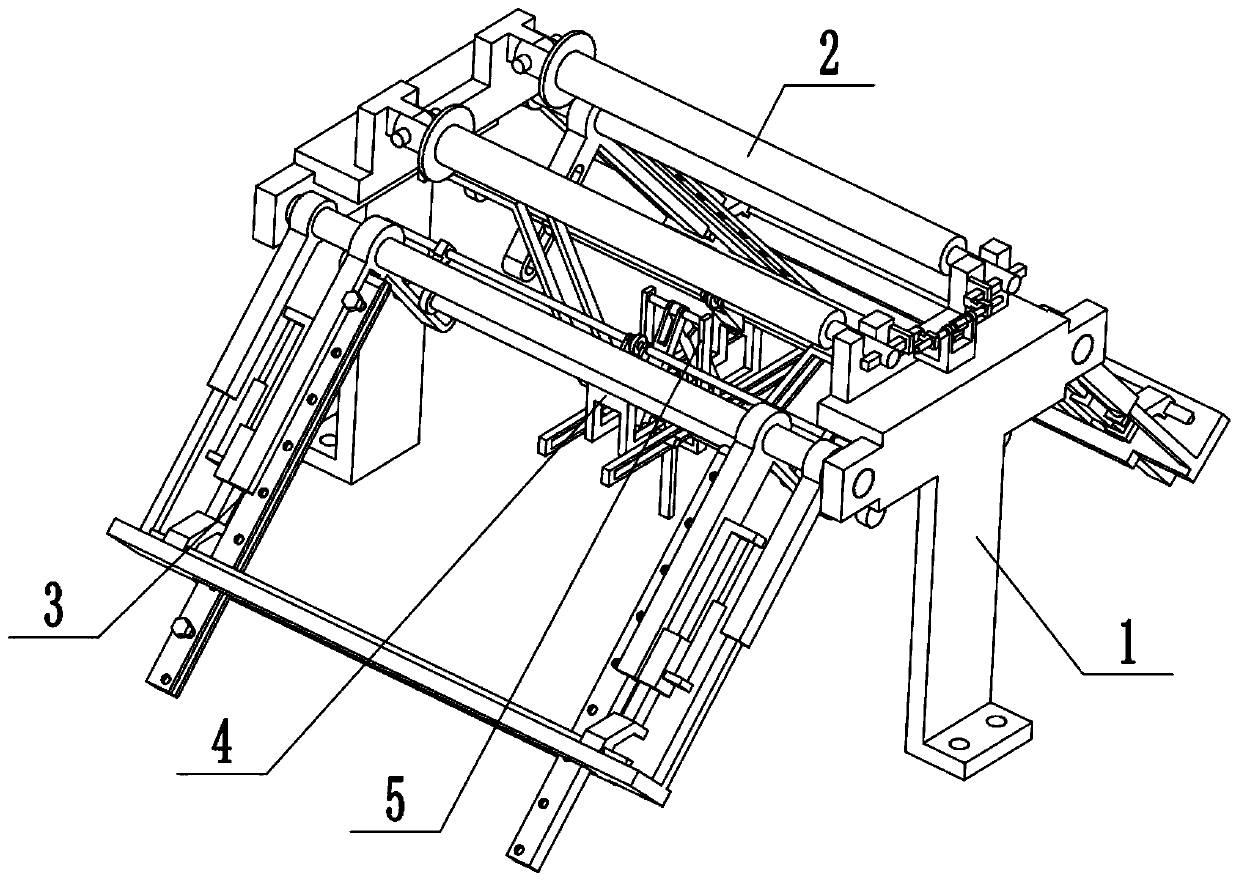

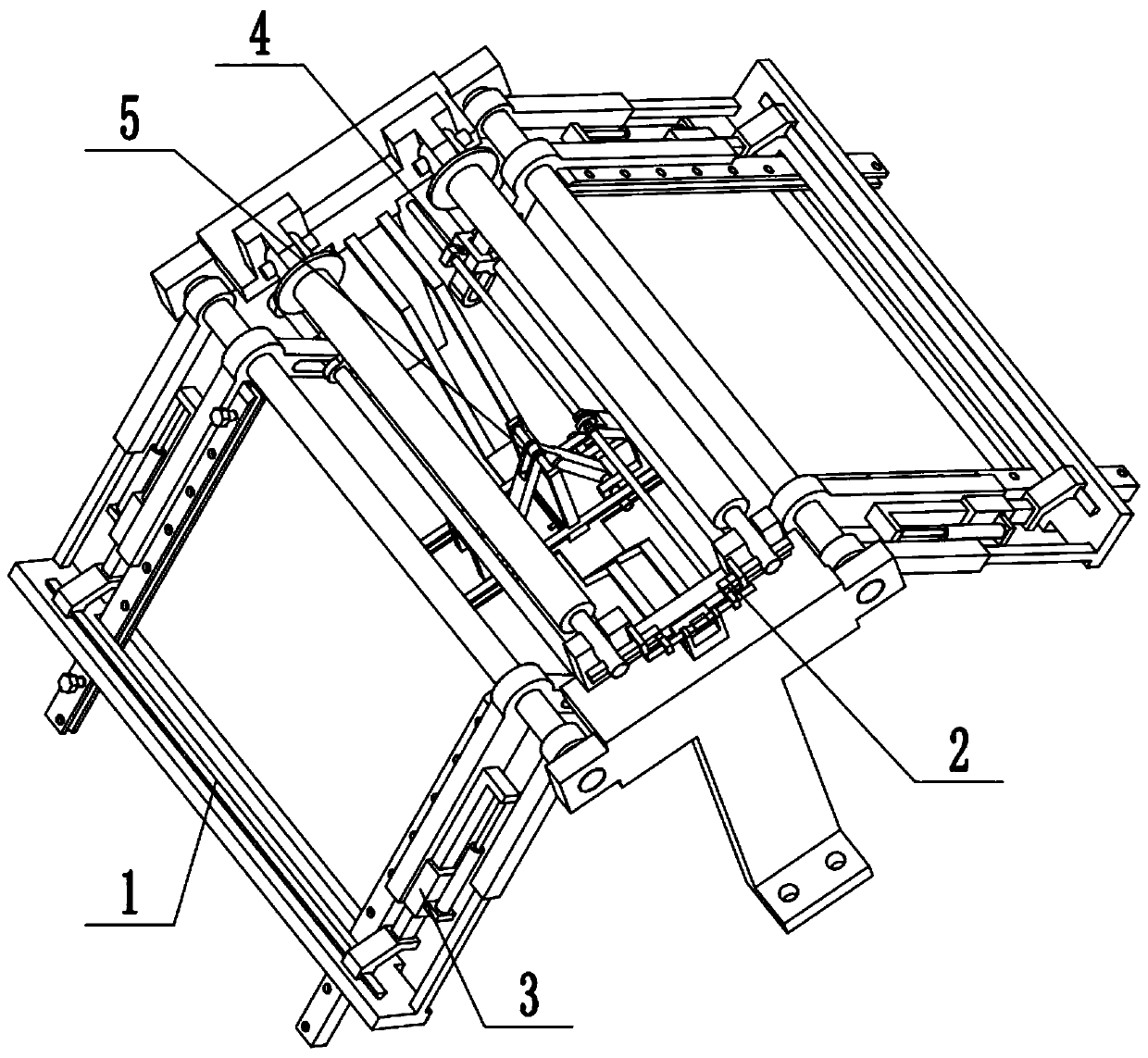

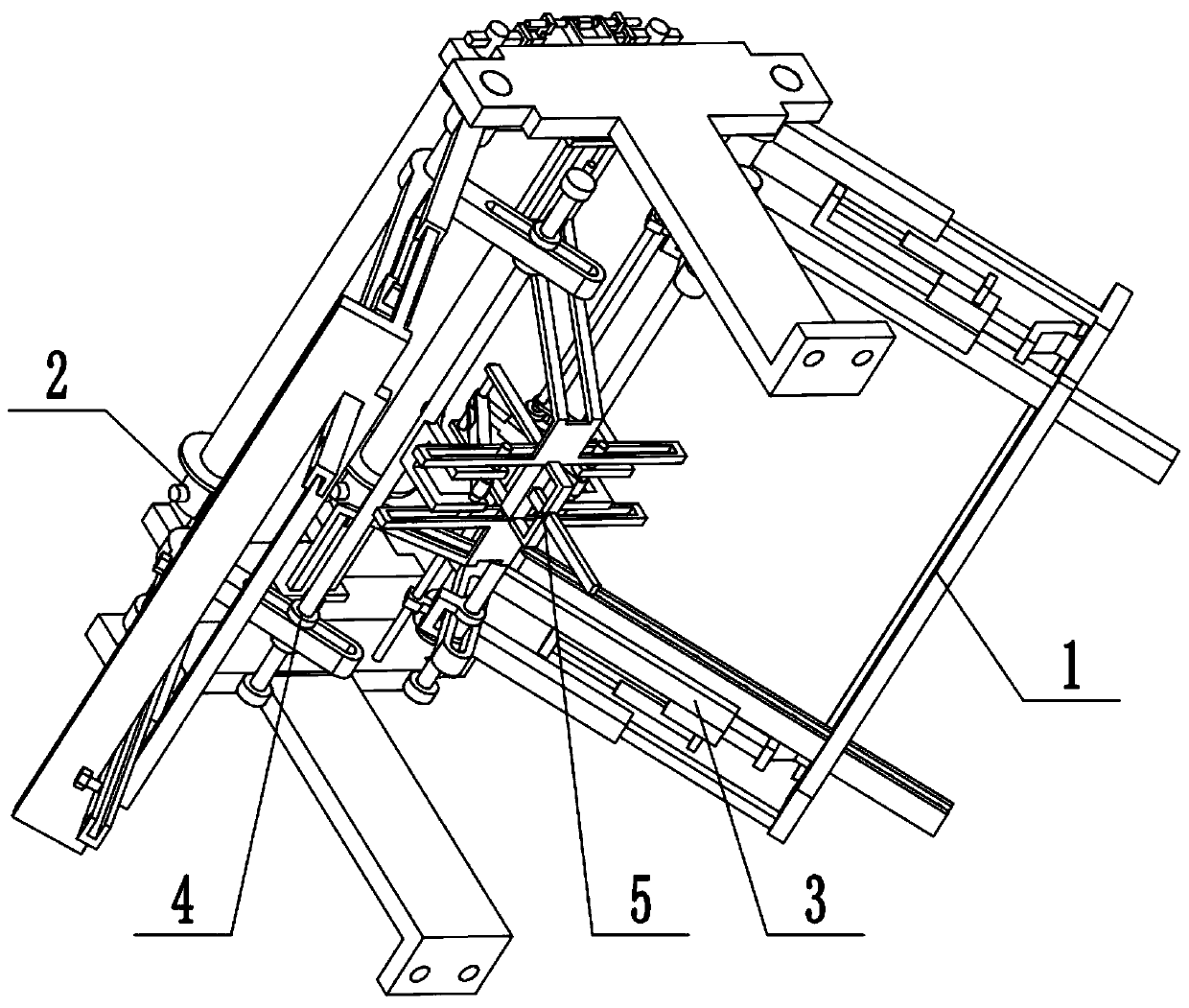

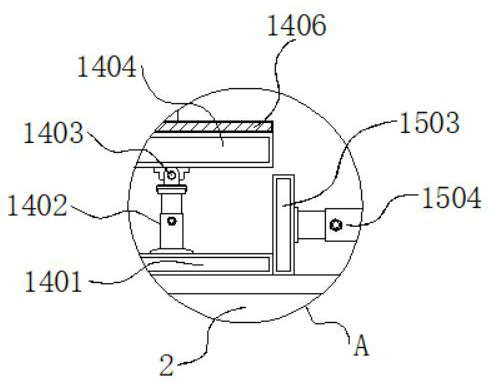

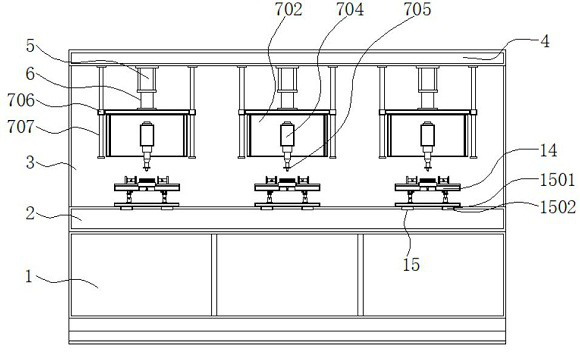

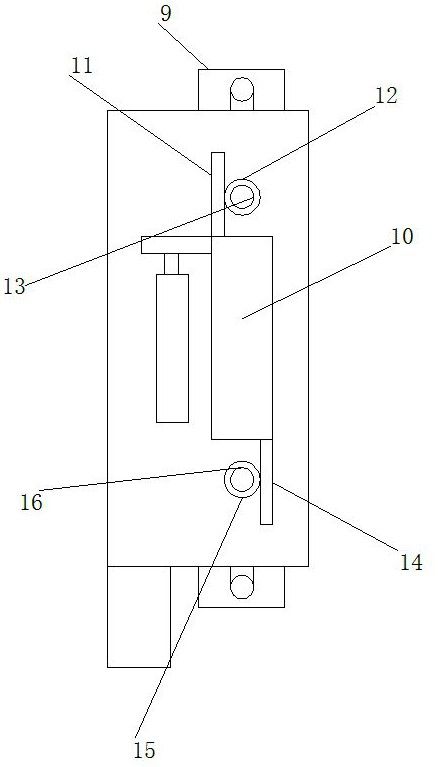

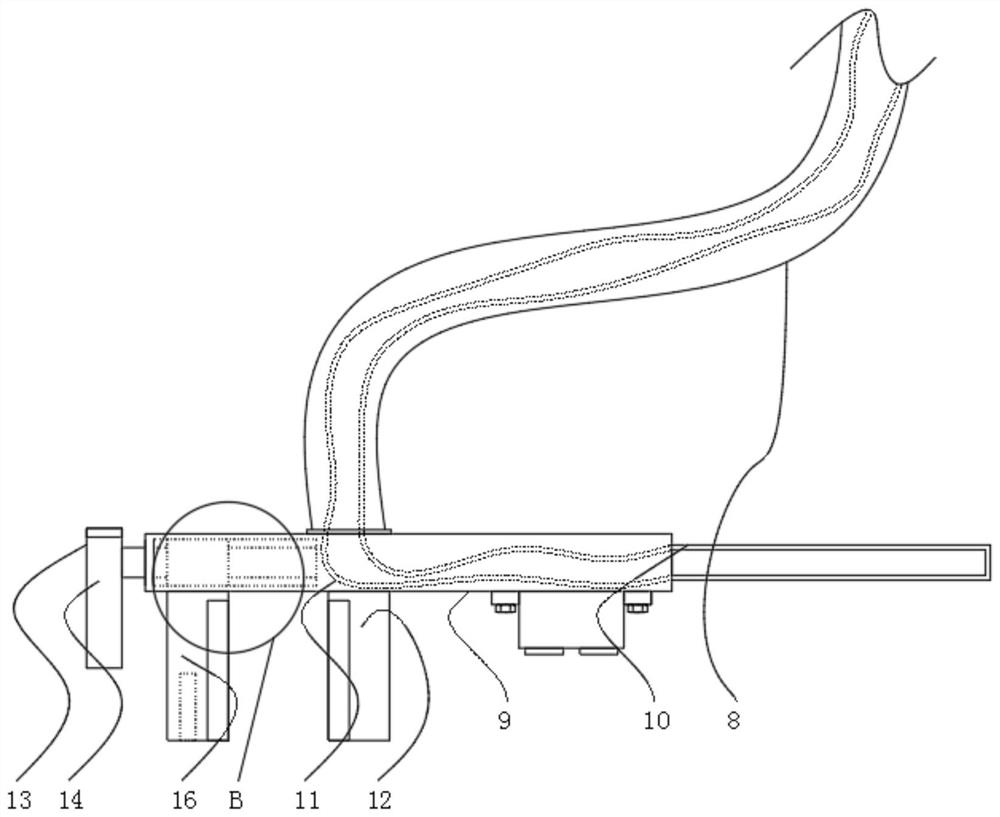

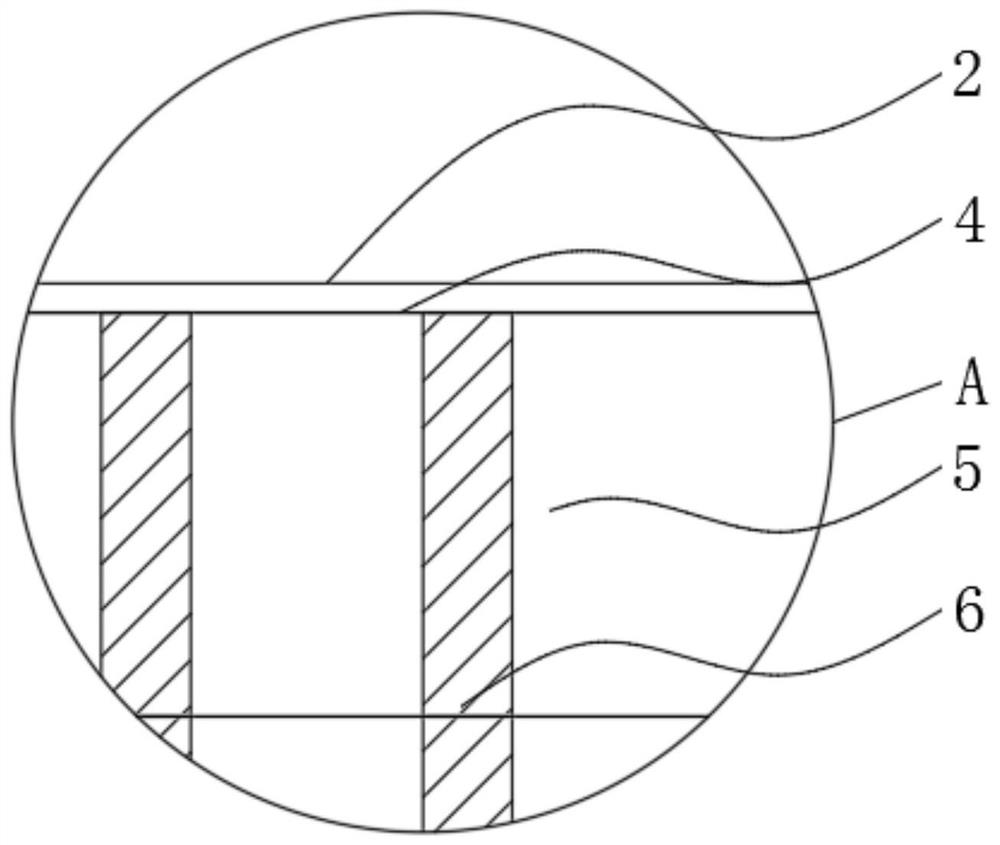

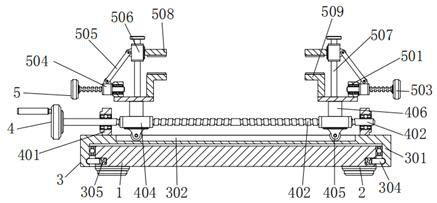

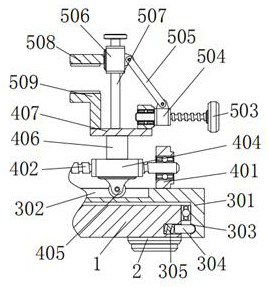

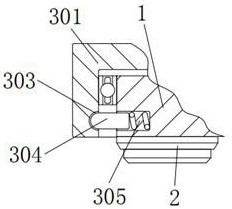

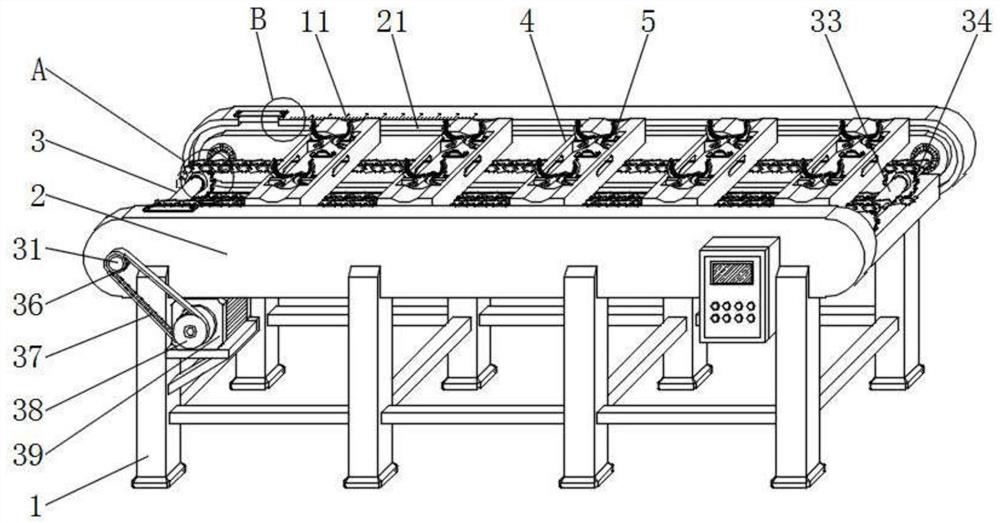

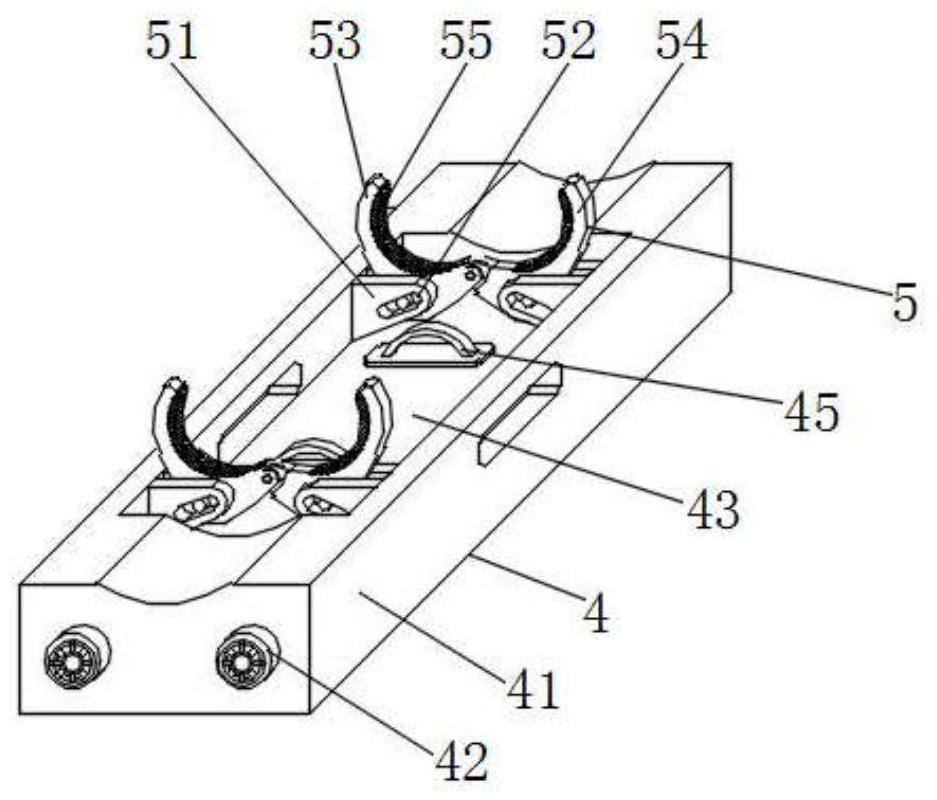

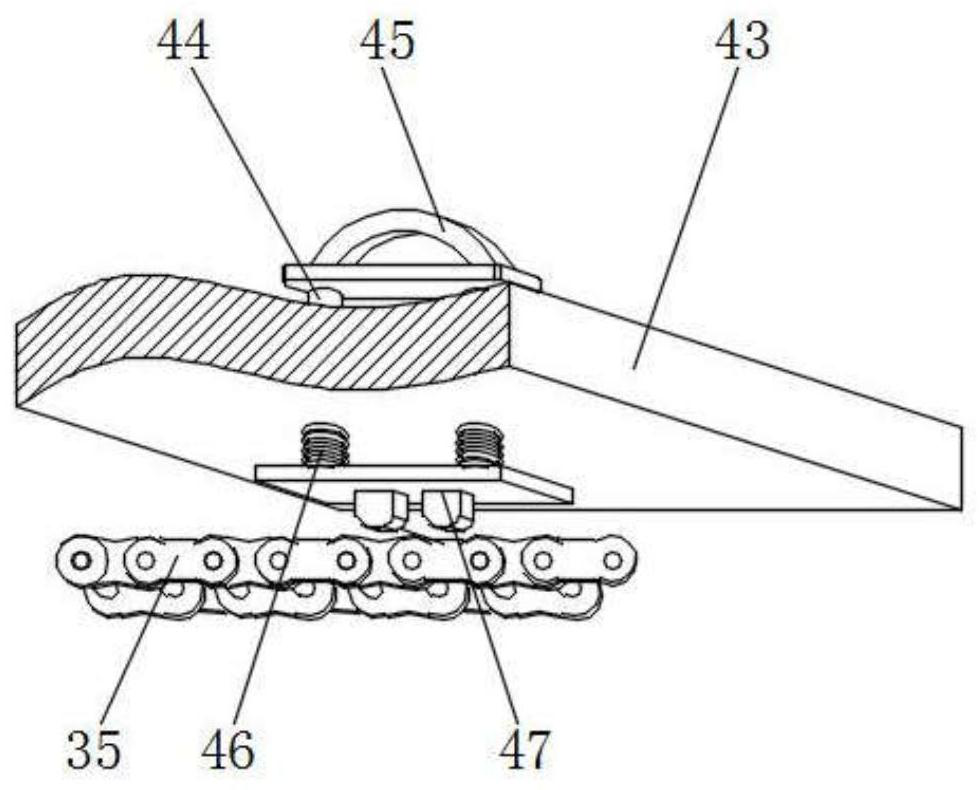

Chain transmission material conveying device

The invention discloses a chain transmission material conveying device which comprises a base, a mounting frame, a driving mechanism, a plurality of connecting mechanisms and a plurality of clamping mechanisms. The mounting frame is arranged at the upper end of the base, the driving mechanism is arranged in the middle of the mounting frame, and the multiple connecting mechanisms are evenly arranged on the inner side of the mounting frame through the driving mechanism. The connecting mechanisms can be driven by the driving mechanism to move in the mounting frame, and the clamping mechanisms are symmetrically arranged on the connecting mechanisms. According to the device disclosed in the invention, the special clamping mechanisms are arranged, the materials are clamped through the self weights of the materials, operation is easy and convenient, rapid positioning clamping and rapid discharging in the using process are facilitated, clamping is firm, the materials are prevented from shaking or falling off in the conveying process, and the detachable connecting mechanisms are adopted in the clamping mechanisms. The number of clamping parts can be increased and decreased conveniently, the distance between the clamping parts can be adjusted conveniently, meanwhile, driving of the chain is adopted as the power on the whole, the strength is higher, and the bearing capacity is better.

Owner:JILIN UNIV

Textile material positioning device

InactiveCN111515881AEasy to processConvenient positioning and clampingSevering textilesWork holdersStructural engineeringMechanical engineering

The invention relates to the technical field of application of textile positioning devices, in particular to a textile material positioning device which comprises a fixing frame, a winding drum sleeving frame, material fixing mechanisms, width adjusting parts and an angle adjusting part. The textile material positioning device has the advantages that materials can be horizontally fixed and can also be obliquely fixed at a certain angle. The winding drum sleeving frame is arranged at the upper end of the middle of the fixing frame, the two material fixing mechanisms are symmetrically arranged at the two ends of the fixing frame, the two width adjusting parts are connected with the two material fixing mechanisms in a matched mode correspondingly, and the angle adjusting part is fixedly connected to the middle of the fixing frame, is connected with the two width adjusting parts in a matched mode, and is used for adjusting the angles of the two material fixing mechanisms.

Owner:常贵振

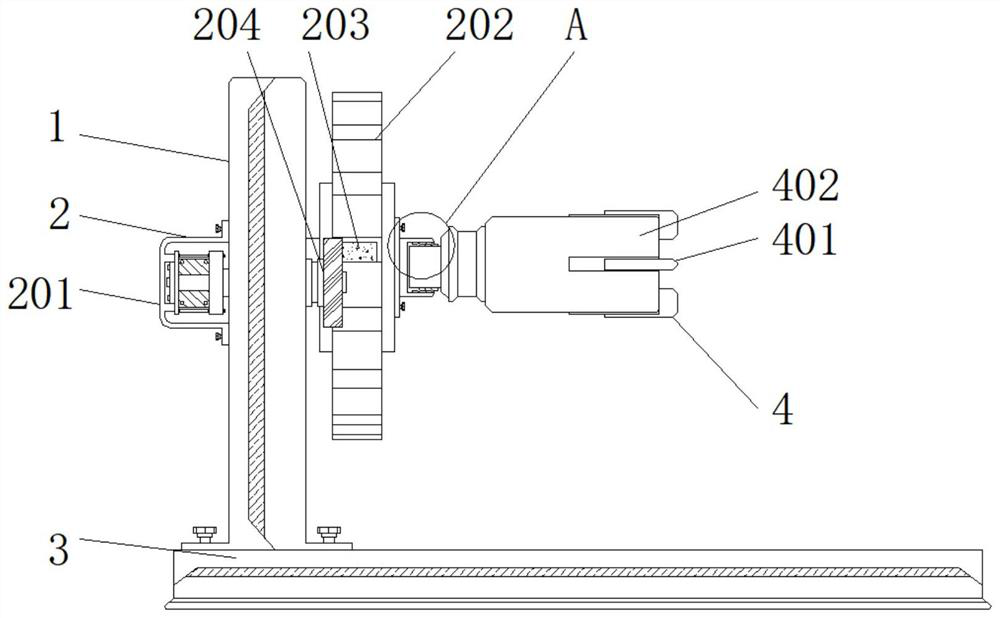

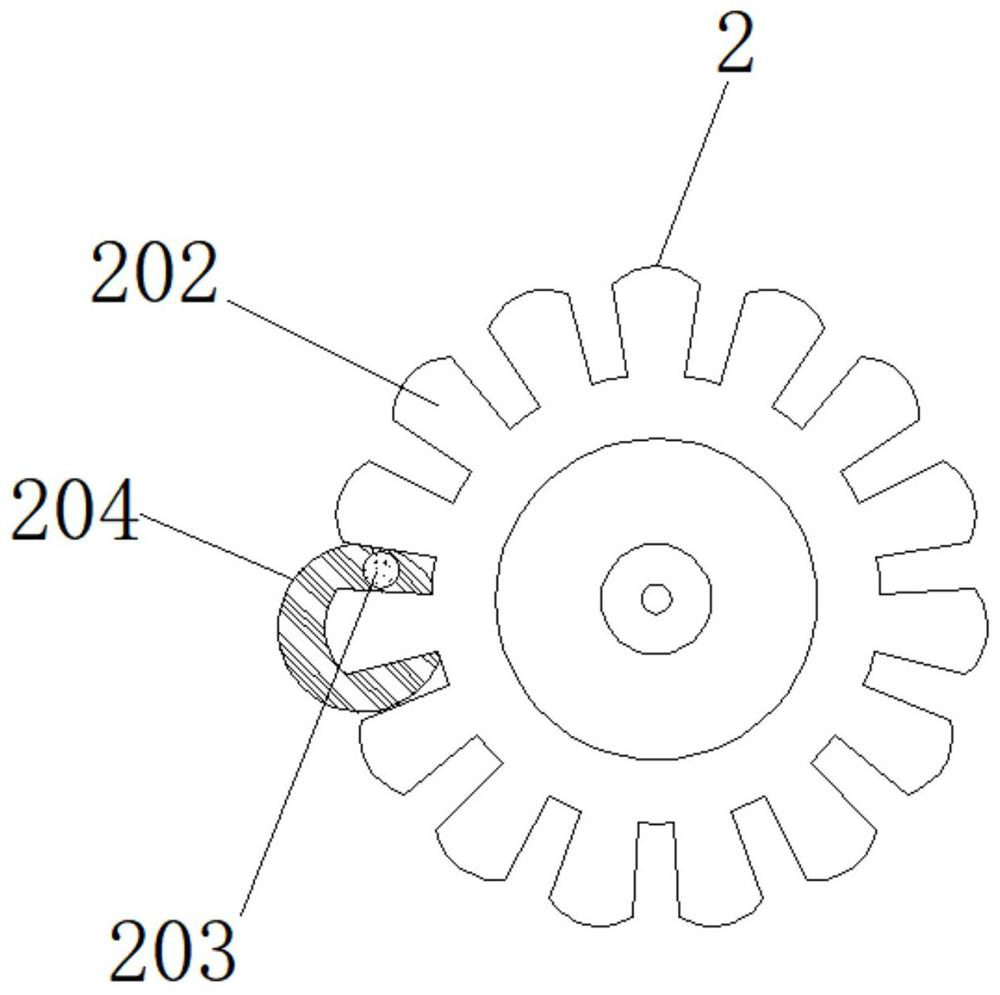

Rotatable positioning and clamping mechanism

PendingCN112059676AIncreased flexibility of useEasy to adjustPositioning apparatusMetal-working holdersPhysicsElectric machinery

The invention discloses a rotatable positioning and clamping mechanism which comprises a supporting rod and a base. The supporting rod is fixed to one side of the top end of the base, a rotating structure is fixed to one side of the supporting rod, the rotating structure comprises a driving motor, a gear, a push block and a rotating disc, the driving motor is fixed to the middle position of the left side of the supporting rod, and the gear is movably arranged at the middle position of the right side of the supporting rod. According to the rotatable position and clamping mechanism, a clamping block is fixed to the gear on one side, so that the clamping block can be turned over by rotating the gear, and a clamped workpiece is rotationally adjusted; the use flexibility of equipment is improved, gear rotation is mainly achieved by clamping a push block on a rotary disc on one side of the gear into a tooth groove of the gear, the driving motor is fixed to the rotating disc, so that the rotating disc and the push block on the rotating disc are driven to rotate when the driving motor is started, then the gear is driven to rotate slowly, the gear rotates by a grid when the rotating disc rotates by a circle, a machined workpiece is rotationally adjusted slowly , and therefore adjustment is more convenient.

Owner:REED XINXIANG ROAD INC

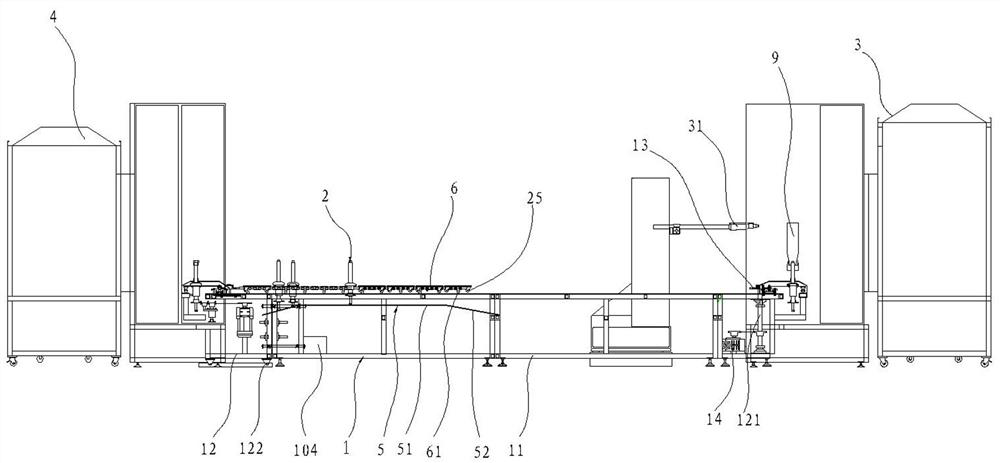

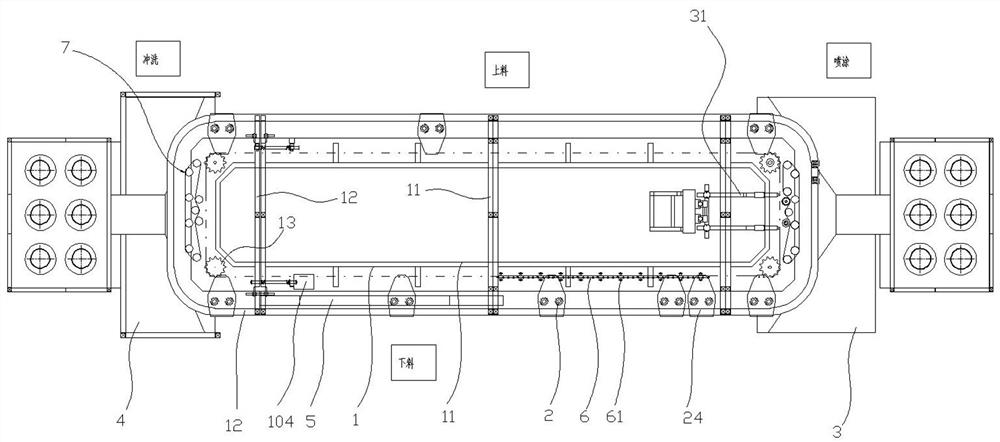

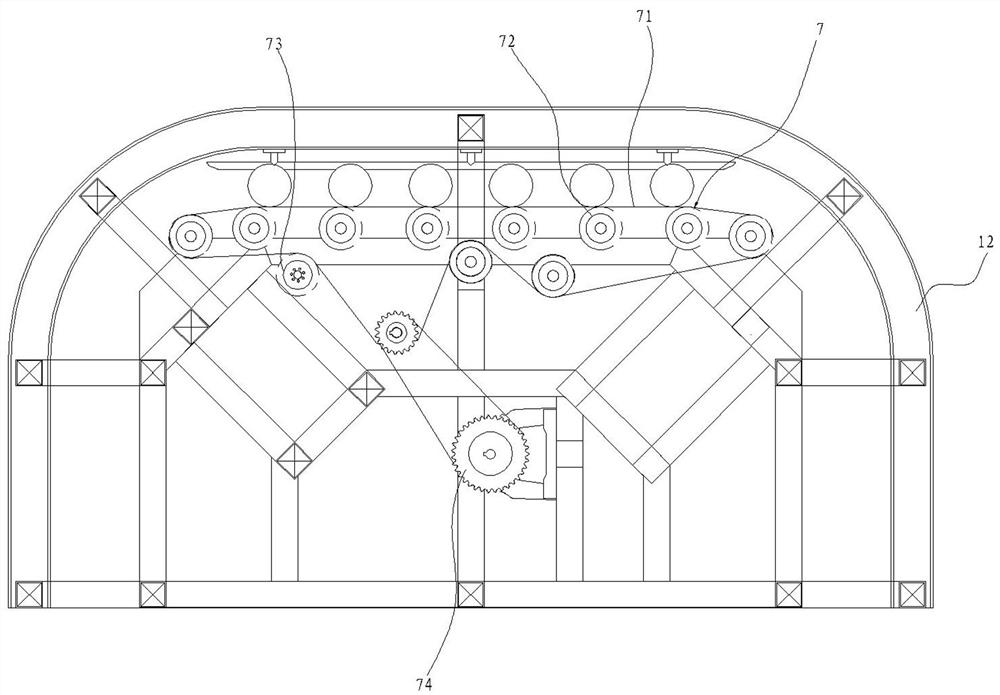

Automatic spraying equipment

PendingCN112354740AConvenient positioning and clampingRealize automatic loading and unloadingSpraying apparatusPhysicsEngineering

The invention discloses automatic spraying equipment which comprises a rack and a conveying chain, a plurality of clamping mechanisms are arranged on the rack, the conveying chain drives the clampingmechanisms to move, each clamping mechanism comprises a mounting plate, a body and a clamping jig, and a chain roller set is connected to the bottom of the conveying chain; an inner side baffle arranged in the length direction of the conveying chain is arranged on the portion, located on the inner side of the conveying chain, of the rack and covers the conveying chain, an outer side baffle arranged in the length direction of the conveying chain is arranged on the portion, located on the outer side of the conveying chain, of the rack, and a channel used for allowing the clamping jig to extend out is formed between the inner side baffle and the outer side baffle; and the inner end of each mounting plate is fixedly connected to the conveying chain, and the bottom of the outer end of each mounting plate is connected with the clamping roller set used for being arranged on the rack in a rolling mode. The automatic spraying equipment can effectively prevent paint or sprayed powder generated by a spray gun from being deposited on the conveying chain, clamping of a mechanical arm is facilitated, and automatic feeding and discharging are achieved.

Owner:宁波祺瑞涂装设备有限公司

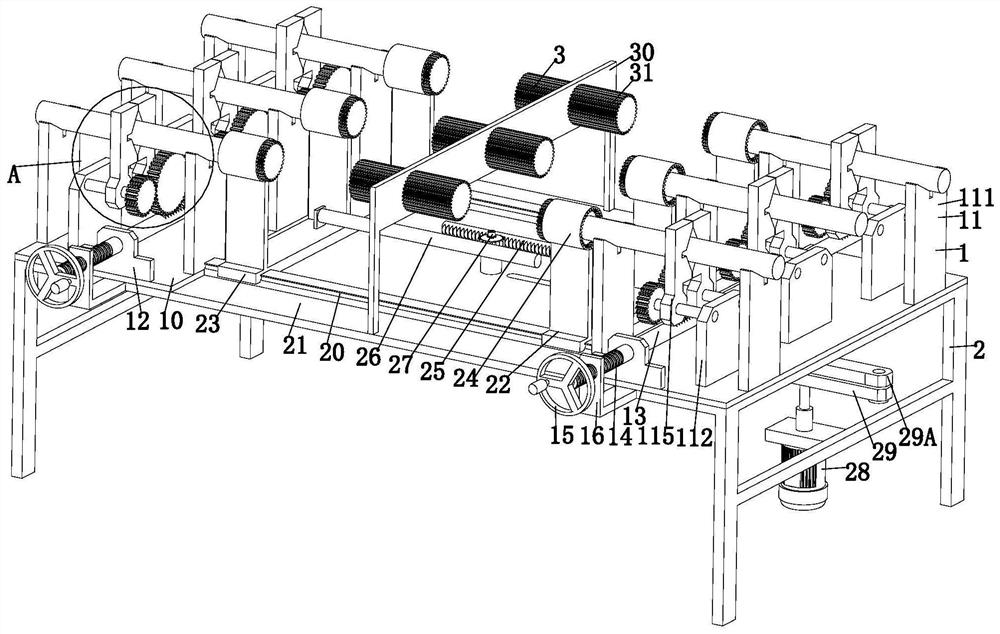

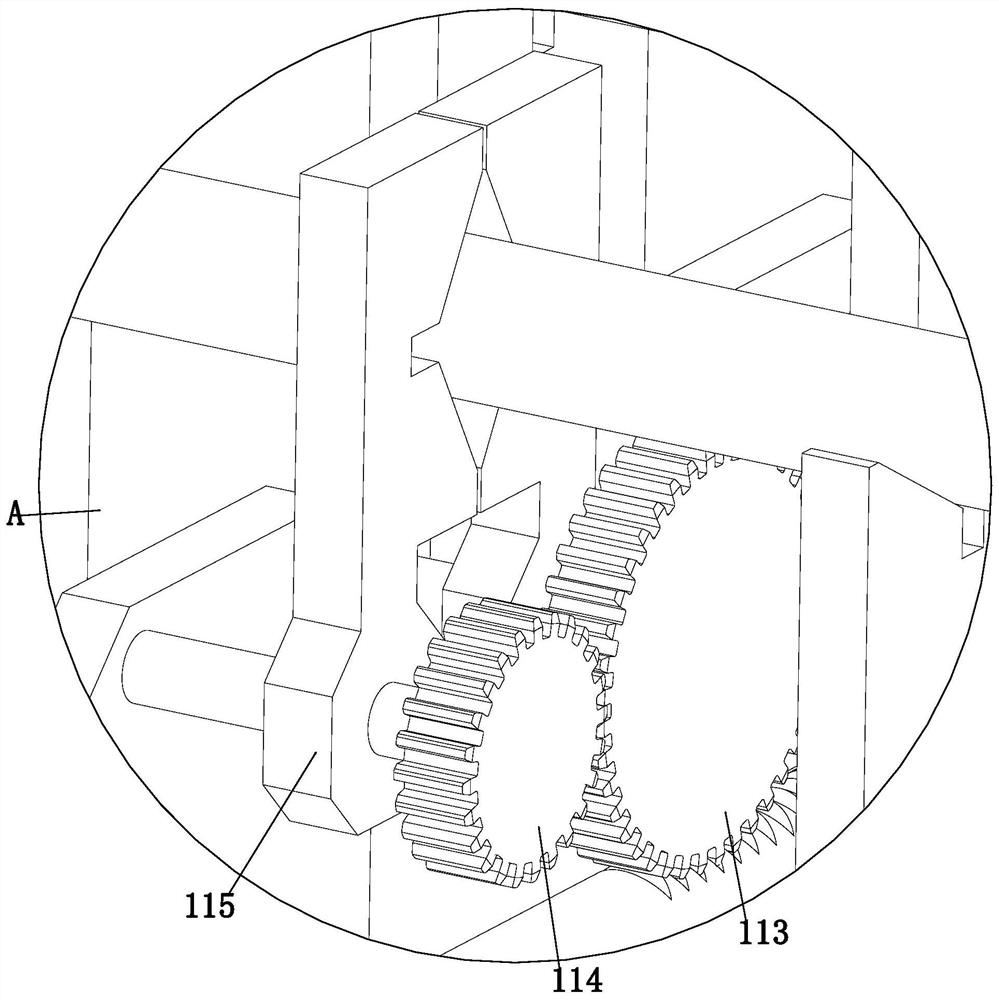

Automobile turbine shaft manufacturing process

InactiveCN112518477AConvenient positioning and clampingAvoid wear and tearEdge grinding machinesGrinding drivesProcess engineeringMechanical system

The invention provides an automobile turbine shaft manufacturing process. The process comprises clamping mechanisms, an actuating mechanism and a polishing mechanism, wherein the clamping mechanisms are mounted on the actuating mechanism in a bilateral symmetry mode, and the polishing mechanism is arranged between the two clamping mechanisms and is mounted on the actuating mechanism. Through the process, the problem that a whole mechanical system cannot work normally due to the existence of burrs, and consequently the reliability and stability are reduced is solved; and the problems that whena machine with burrs does mechanical motion or vibrates, the falling burrs cause that the sliding surface of the machine is abraded too early, the noise is increased, even mechanisms are stuck, and the action fails are solved.

Owner:聂艳

Positionable automatic welding device for machining cooling fin of computer CPU

InactiveCN112139716AAvoid offsetImprove cooling efficiencyWelding/cutting auxillary devicesAuxillary welding devicesPhysicsHeat sink

The invention discloses a positionable automatic welding device for machining a cooling fin of a computer CPU and relates to the technical field of cooling fin welding, the positionable automatic welding device comprises a machine body, a welding structure, a conveying belt and a positioning mechanism, a workbench is fixed above the machine body, back plates are installed on the two sides of the outer portion of the upper portion of the workbench, and a top plate is fixed to the upper sides of the back plates. An air cylinder is mounted below the middle of the top plate, a piston rod is arranged on the lower side of the air cylinder, the welding structure is mounted below the piston rod, an upper plate is mounted above the top plate, connecting rods are fixed to the two sides of the lowerportion of the upper plate, a mounting plate is fixed to the lower portions of the connecting rods, and cooling fans are mounted on the two sides of the lower portion of the mounting plate. The positionable automatic welding device has the beneficial effects that the height of a lifting plate can be conveniently adjusted in a rising and falling mode through the air cylinder and the piston rod so as to drive a welding gun and a welding head to descend, the position of the welding gun can be conveniently adjusted through an electric push rod, and a cooling fin main body can be conveniently welded through the welding gun and the welding head.

Owner:东莞市夯牛机电科技有限公司

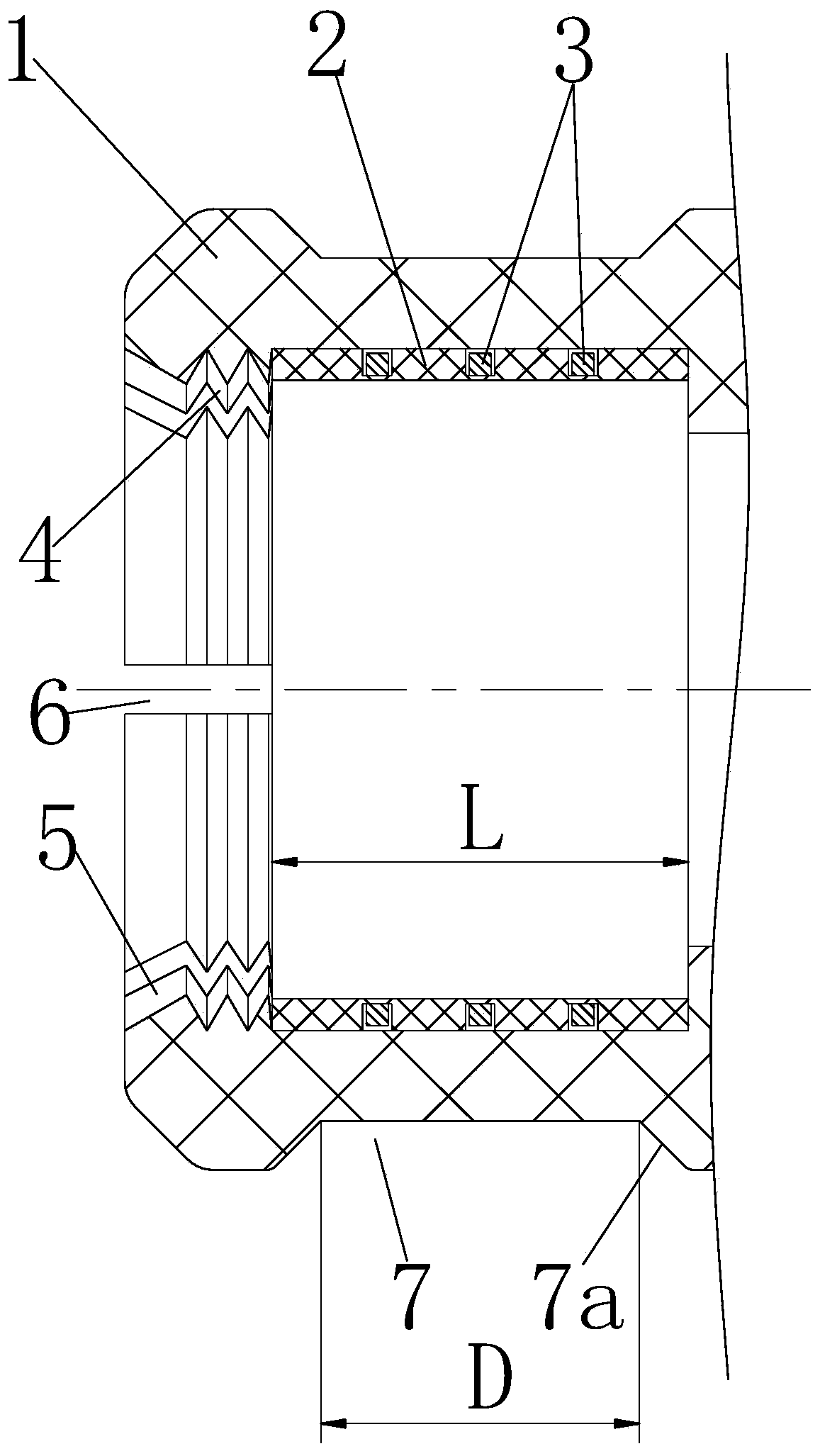

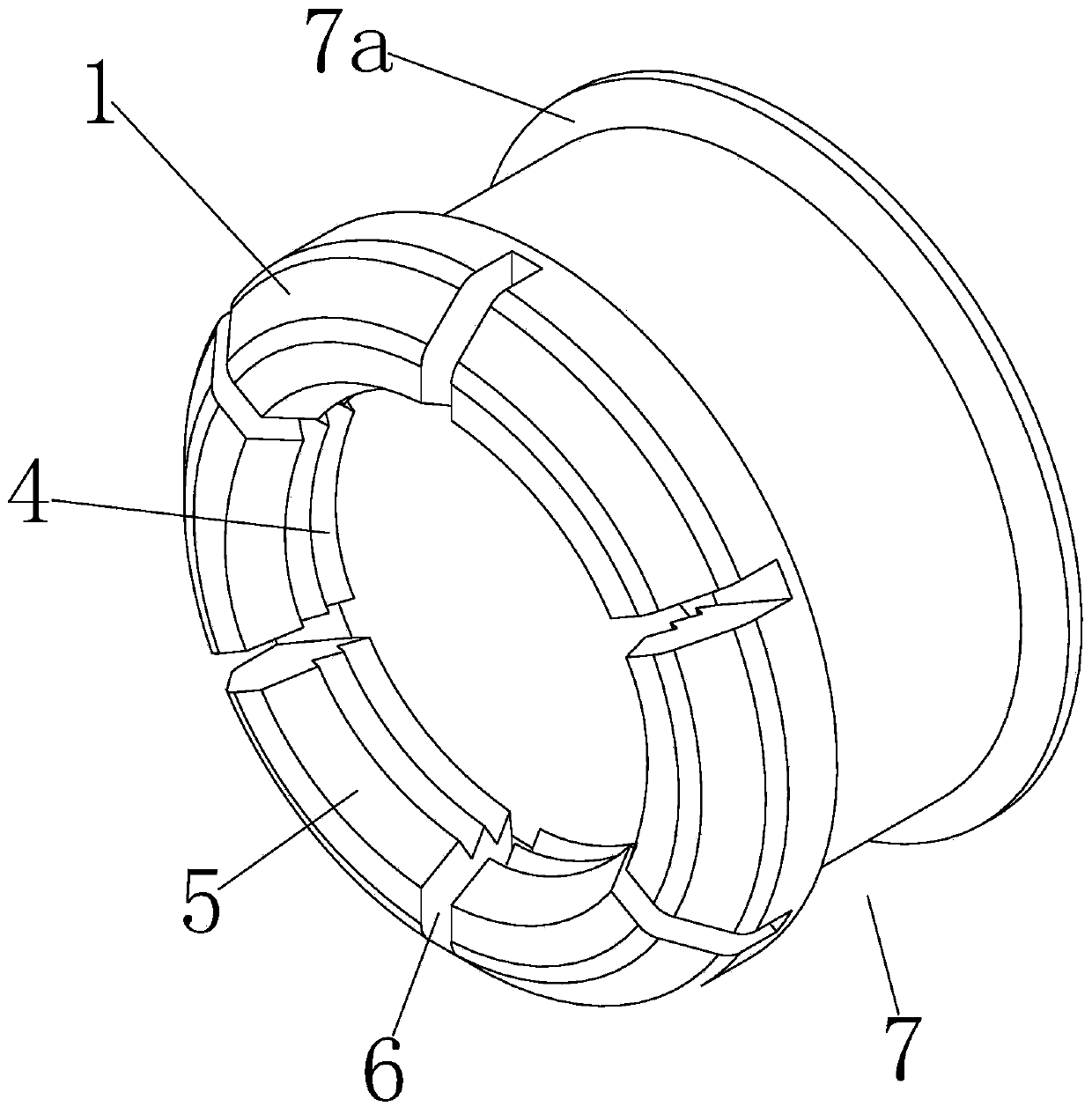

Connecting structure of electromagnetic hot melting pipe fitting

PendingCN110630843APlay a role in heat productionReduce weightPipe connection arrangementsPipe fittingHot melt

The invention discloses a connecting structure of an electromagnetic hot melting pipe fitting. The connecting structure comprises a pipe fitting body, wherein a hot melting inner sleeve is embedded onthe inner wall of a socket of the pipe fitting body, a plurality of electromagnetic induction heat production supporting rings are inlaid in the hot melting inner sleeve in the axial direction at intervals, and the electromagnetic induction heat production supporting rings are coaxially arranged with the hot melting inner sleeve. According to the connecting structure, the hot melting inner sleeveis embedded on the inner wall of the socket of the pipe fitting body, and the plurality of electromagnetic induction heat production supporting rings are inlaid in the hot melting inner sleeve in theaxial direction at intervals, so that heat can be generated by the electromagnetic induction heat production supporting rings through an electromagnetic welding clamp so as to perform hot melting connection on the hot melting inner sleeve and a pipe needing to be connected, the structure is simple, and the operation is convenient; meanwhile, due to the fact that only the plurality of electromagnetic induction heat production supporting rings are adopted to perform hot melting on the hot melting inner sleeve and the pipe, the overall weight of the pipe fitting connecting structure is light, and the cost is low; and moreover, the electromagnetic induction heat production supporting rings can not only play the heat production role, but also can play the supporting role, and the connecting structure is applicable to the connection of pipe fittings.

Owner:武汉世纪金牛管件技术有限公司

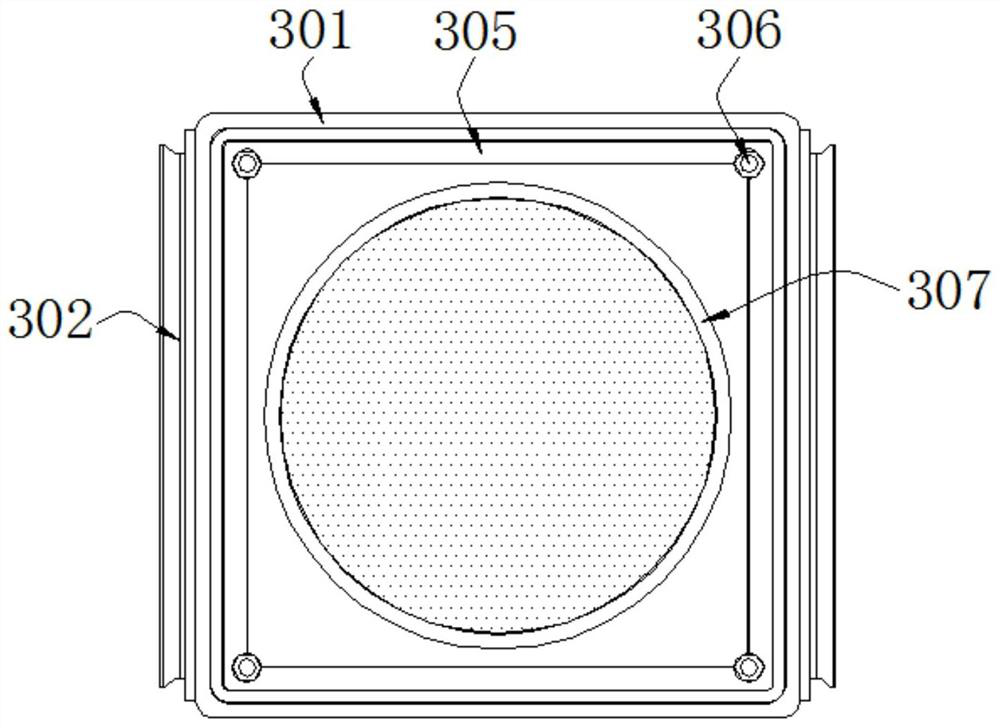

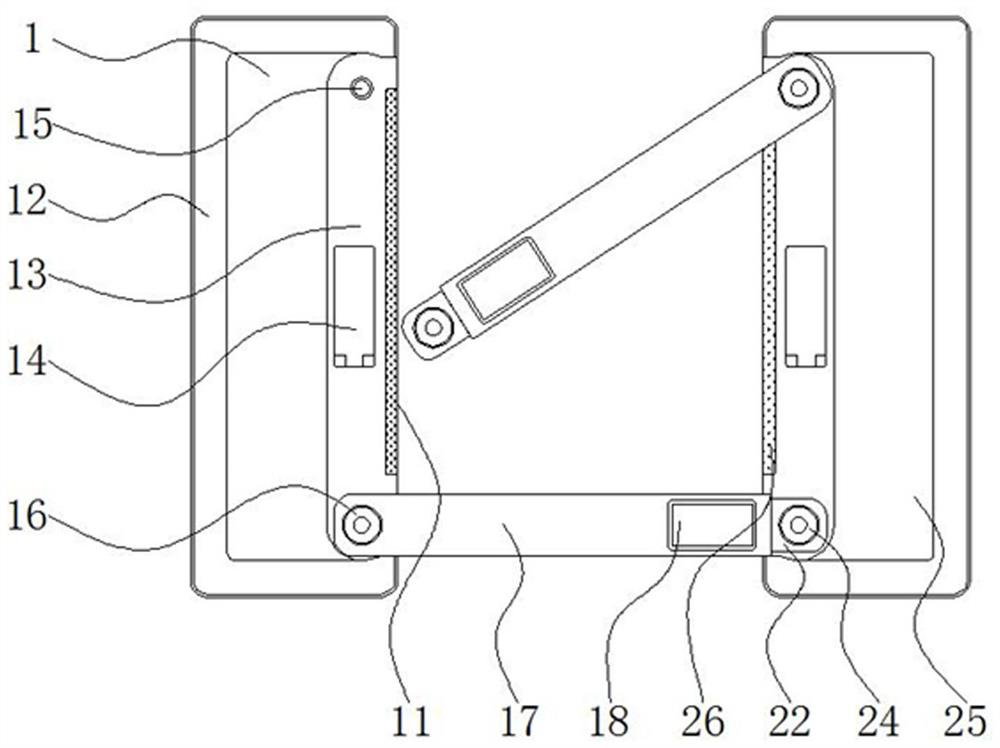

An automatic detection system for display status of display screen

ActiveCN109540476BConvenient positioning and clampingCheck qualityWork holdersTesting optical propertiesMechanical engineeringElectrical and Electronics engineering

The invention belongs to the field of display screens, in particular to an automatic detection system for the display status of a display screen. Aiming at the problems that traditional detection equipment is inconvenient to operate and difficult to detect the brightness of the display screen, the following scheme is proposed, including the casing and the inside of the casing There is a partition, the top of the partition is provided with a fixed baffle, one end of the fixed baffle is vertically welded with a fixed splint, one side of the fixed splint is provided with a movable plate slidingly connected with the fixed baffle, and the movable plate is close to one side of the fixed splint A receiving groove is opened on the side, and a detection board is installed inside the receiving groove. The present invention clamps and positions the display screen during detection, and the positioning and clamping are convenient and fast, which changes the disadvantages of the traditional manual clamping and positioning operation, which is troublesome and inefficient, and at the same time effectively detects the light intensity of each position on the display surface of the display screen, thereby distinguishing Whether there is a problem of uneven brightness on the display screen, and effectively detect the quality of the display screen.

Owner:安徽万源信息科技有限公司

Mixing system suitable for polyurethane production and processing

The invention discloses a mixing system suitable for polyurethane production and processing, and relates to the technical field of polyurethane production and processing, the mixing system comprises a bearing base and a vibration assembly, a fixed frame body is arranged at the upper end of the bearing base close to the edge, and the vibration assembly used for polyurethane mixing is arranged at the center position of the upper end of the bearing base. Through mutual cooperation of a plurality of assemblies, full and rapid mixing of polyurethane production raw materials is achieved, the production efficiency of polyurethane is effectively improved, the mixing efficiency and the mixing effect of the polyurethane raw materials are greatly improved in the mode that stirring mixing is matched with vibration mixing, meanwhile, the material barrel and the device are of a separated structure, and the material barrel and the device are convenient to use. And the interior of the material barrel is convenient to clean while mixed polyurethane is collected and guided out, polyurethane raw materials adhered to the inner wall of the material barrel for a long time cannot be fully mixed, the production quality of the polyurethane is influenced, and structural adjustment is conveniently carried out according to the actual mixing condition.

Owner:何业莉

A patch device with heat equalization function for intelligent manufacturing of tablet computers

The invention relates to a patch device with a heat soaking function for intelligent manufacturing of tablet computers, comprising an equipment casing and a positioning assembly. The box and the second belt conveyor, the inner rear wall of the equipment casing is equipped with a shielding component, the front end of the first motor is connected with a rotating rod, and the outside of the rotating rod is connected with a shielding plate through a connecting pin, the said The left and right sides of the shielding plate are connected with auxiliary support feet, and the lower end of the shielding plate is connected with a first contact sensor. The beneficial effects of the present invention are: the patch device with heat soaking function used in the intelligent manufacture of tablet computer can facilitate the flow of glue liquid, thereby facilitating the gluing of the equipment, and the shielding and positioning components of the equipment can be rotated, thereby facilitating the shielding and positioning of the equipment , the device can accurately heat the patch to facilitate the adhesion of the glue, the device can position the patch, and the device can hold the patch stably.

Owner:深圳市阿龙电子有限公司

Clamp for manufacturing iron wedge by band sawing machine

PendingCN113290409AGuaranteed stabilityConvenient positioning and clampingPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a clamp for manufacturing an iron wedge by a band sawing machine. The clamp comprises a mounting plate, a first mounting seat, a second mounting seat, a second clamping plate and a first clamping plate, wherein the mounting plate is fixedly welded to the first mounting seat, and the mounting plate and the second mounting seat are both fixedly mounted on the band sawing machine; and a second connecting part is fixedly welded to the front side end of the second mounting seat, the first clamping plate is fixedly mounted on the second connecting part, a first connecting part is fixedly mounted on the front side face of the first clamping plate, the first connecting part is of a section of channel steel structure, and first mounting holes are formed in the first connecting part. The clamp for manufacturing the iron wedge by the band sawing machine is formed by combining the mounting plate, the first mounting seat, the second mounting seat, the second clamping plate and the first clamping plate, and a positioning part formed by combining a positioning rod mounting seat and a positioning rod is arranged on the first mounting seat, so that the stability of clamping a workpiece is ensured; and workpieces with different sizes can be positioned and clamped very conveniently.

Owner:SHANDONG GOLD GUILAIZHUANG MINING CO LTD

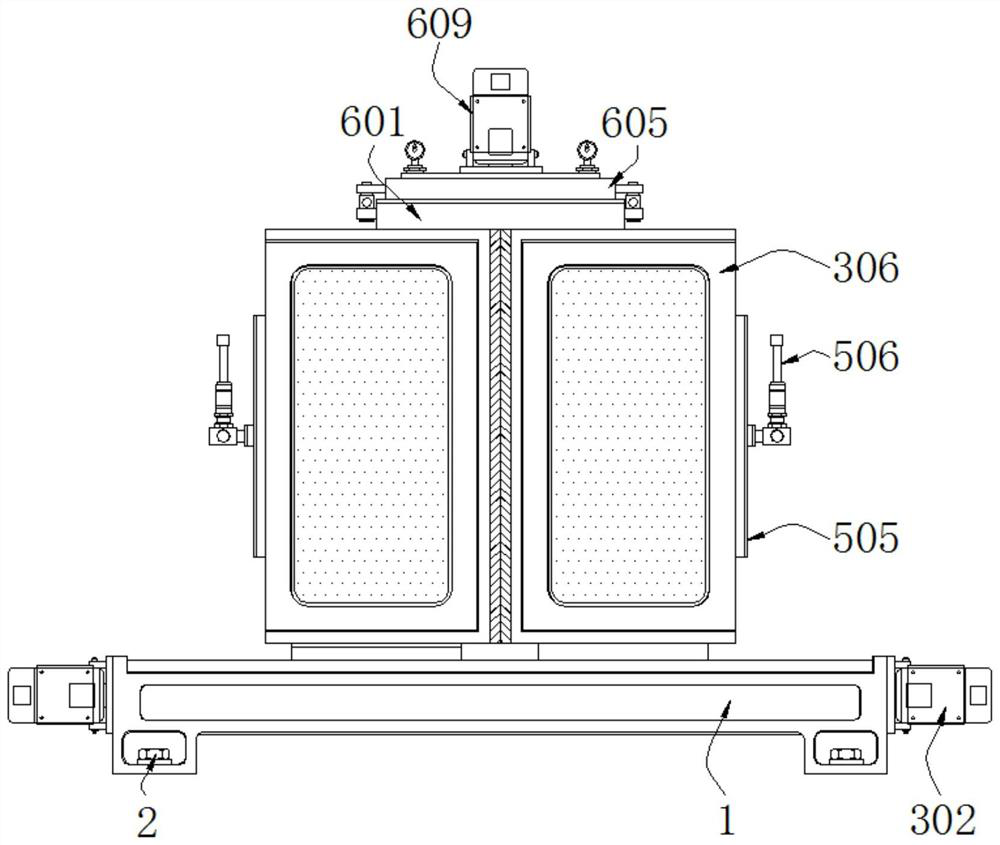

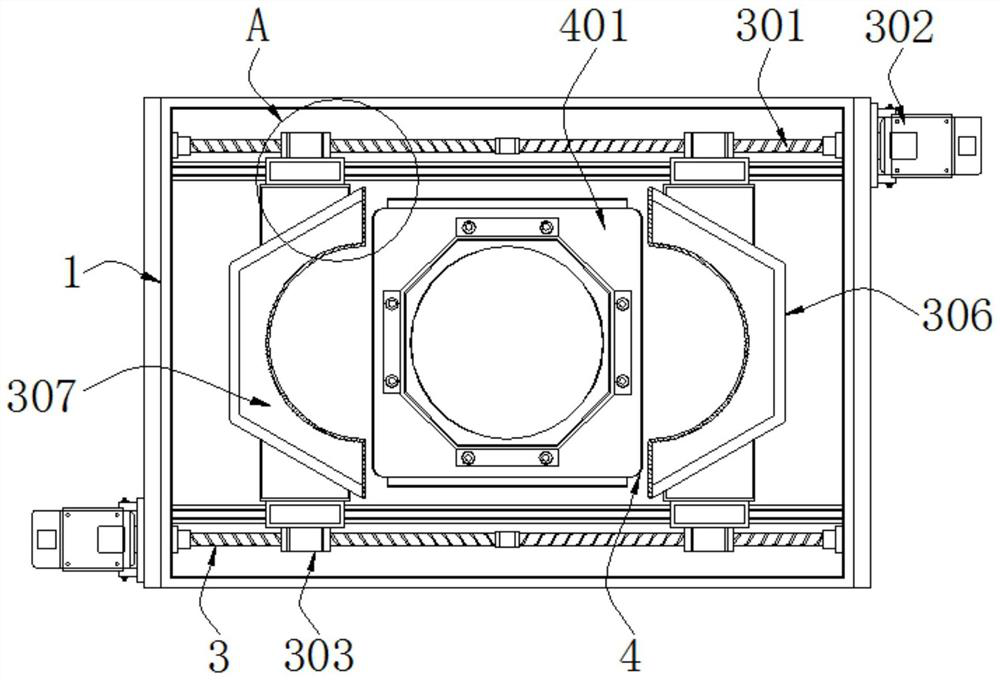

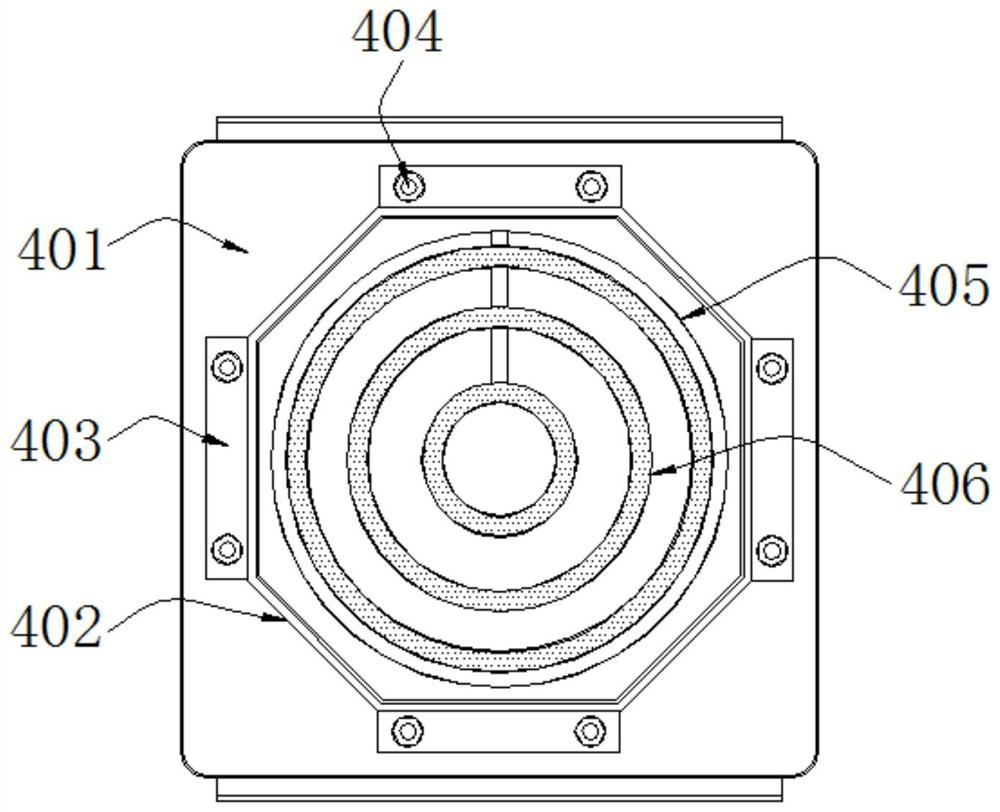

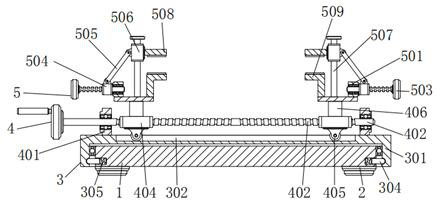

High-sealing-performance bioreactor without dead-corner sterilization

PendingCN114736778AImprove sealingAvoid conditions that affect the effectiveness of the biological responseBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringMechanical engineering

The invention discloses a dead-corner-free sterilization high-sealing-performance bioreactor, and relates to the technical field of bioreactors, the dead-corner-free sterilization high-sealing-performance bioreactor comprises a bearing seat and a sterilization assembly, fixing bolts are arranged in four corners of the bearing seat in a penetrating manner, and protection assemblies for opening and closing are arranged at the front end and the rear end of the upper end of the bearing seat; and the disinfection assembly for biological sterilization is arranged at the central position of the upper end of the bearing seat. Through mutual cooperation of a plurality of components, high sealing performance of the reactor is ensured while four-corner-free sterilization in the biological reaction process is realized, the situation that gas leaks and enters to affect the biological reaction effect is avoided, meanwhile, good protection and heat preservation effects are achieved, the continuity and effectiveness of the biological reaction process are ensured, and the biological reaction effect is ensured. The high sealing performance of the reactor can be guaranteed without complex operation of workers, the process and state of biological reaction can be detected, and the workers can know the state of the biological reaction at the first time in a remote transmission mode.

Owner:智享生物技术(苏州)有限公司

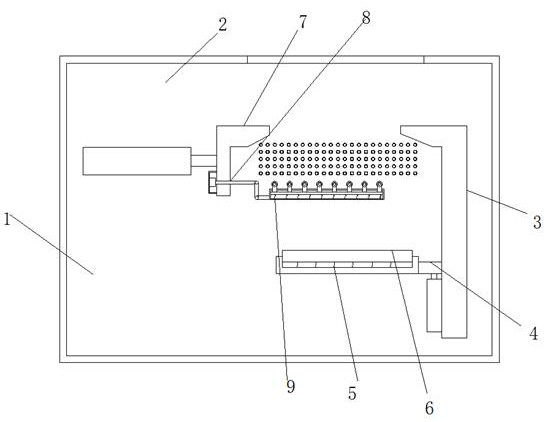

A positioning device for circuit board drilling

ActiveCN112601364BScientific and reasonable structureEasy to useCircuit board tools positioningEngineeringExternal circuit

The invention discloses a positioning device for circuit board drilling, which includes a bottom plate, the four corners of the bottom of the bottom plate are all fixedly connected with a base, and the outer walls of two arc-shaped clamping rods are respectively matched with the inner walls of the left and right sides of the outer wall of the base. , the inner sides of the outer walls of the two arc-shaped clamping rods are provided with springs, the outer walls of the two springs are matched with the inner walls on the left and right sides of the outer wall of the bottom plate, and one end of the spring is fixedly connected to the inner wall of the bottom plate. The other end of the spring is fixedly connected to the outer wall of the arc-shaped clamping rod. The circuit board drilling positioning device can rotate the groove frame when drilling the external circuit board clamped on the board body and the curved rod, so that the groove frame drives the external circuit board to rotate, so that the external circuit board can be driven by the pulley and The chute is connected by sliding, so that when the double-ended screw rotates, it can drive the first sleeve to move left and right stably, so that the curved plate and the plate body can stably position and clamp external circuit boards of different thicknesses.

Owner:扬州依利安达电子有限公司

A mechanical wear alarm device and its alarm system

ActiveCN111175031BEasy to installEasy to useMachine part testingUsing mechanical meansMechanical wearMachine

The invention relates to a mechanical wear alarm device and its alarm system, comprising a machine base and a positioning mechanism. The machine base is arranged with a casing, and side slots are opened inside the left and right ends of the box, and the inner sides of the side slots are A positioning mechanism is installed at the end, and a connecting cable is installed in the middle of the base, and a fixed card seat is fixed at the end of the connecting cable, and a chuck is arranged at the end of the fixed card seat. The beneficial effects of the present invention are: the mechanical wear alarm device and its alarm system can rotate and adjust the position of the positioning seat through the rotation of the side shaft, and then can be used to adjust the orientation of the positioning seat well, such as positioning The seat is rotated to the outside of the side end of the device body for positioning and use, etc., which has the effect of strong convenience and performance. At the same time, it can be screwed through the fixed hole at the end of the positioning seat to facilitate the device body to be placed on the machine. The ends of the parts are easily accessible and have a very high linkage effect.

Owner:洛科斯智能技术(江苏)有限公司

Positioning device for drilling circuit board

ActiveCN112601364AScientific and reasonable structureEasy to useCircuit board tools positioningEngineeringExternal circuit

The invention discloses a positioning device for a drilling circuit board. The positioning device comprises a bottom plate, wherein bases are fixedly connected to the four corners of the bottom of thebottom plate correspondingly, the outer walls of two arc-shaped clamping rods are in clearance fit with the inner walls of the left side and the right side of the outer wall of each base correspondingly, and springs are arranged on the inner sides of the outer walls of the two arc-shaped clamping rods correspondingly; the outer walls of the two springs are in clearance fit with the inner walls ofthe left side and the right side of the outer wall of the bottom plate, one ends of the springs are fixedly connected to the inner wall of the bottom plate, and the other ends of the springs are fixedly connected to the outer walls of the arc-shaped clamping rods. According to the positioning device for circuit board drilling, when an external circuit board positioned and clamped between a boardbody and a curved bar is drilled, a groove frame can be rotated to drive the external circuit board to rotate, so a first sleeve can be driven to stably move left and right through sliding connectionof a pulley and a sliding groove when a double-thread screw rotates, and the circuit board can be positioned and clamped between the board body and the curved bar; therefore, the bent plate and the plate body can stably position and clamp external circuit boards with different thicknesses.

Owner:扬州依利安达电子有限公司

A chain drive conveying device

The invention discloses a chain drive conveying device, which comprises a base, a mounting frame, a driving mechanism, several connecting mechanisms and several clamping mechanisms, the upper end of the base is provided with a mounting frame, and the driving mechanism is arranged The two connecting mechanisms are evenly arranged on the inside of the mounting frame through the driving mechanism, and the connecting mechanism can move in the mounting frame driven by the driving mechanism, and the clamping mechanism is symmetrically arranged on the connecting mechanism; in the device of the present invention, a special clamp is provided. The holding mechanism uses the self-weight of the material to realize the clamping of the material. It is easy to operate and convenient for quick positioning and clamping and quick unloading during use, and it is relatively firm after clamping to avoid shaking or falling off of the material during the conveying process, and The clamping mechanism adopts a detachable connection mechanism, which facilitates the increase and decrease of the number of clamping parts and the adjustment of their spacing. At the same time, the drive of the chain is used as the power as a whole, which has greater strength and better carrying capacity.

Owner:JILIN UNIV

Gyro pendant production and processing equipment with positioning and automatic assembling functions

PendingCN112355607AEasy to installComponents are easy to installMetal working apparatusEngineeringAssembly machine

The invention discloses gyro pendant production and processing equipment with positioning and automatic assembling functions. The equipment comprises an assembling case, a main body pushing assembly is installed on the left side of the top of the assembling case, and a fixing block assembling mechanism is arranged in a gap between the right side end of an operation table and the right side end ofa shell pushing assembly. According to the equipment, main body positioning clamps are symmetrically arranged on the top end face of the operation table in a crossed mode, the bottoms of the main bodypositioning clamps and flow guide grooves of the main body pushing assembly and the shell pushing assembly are formed in the same horizontal line, and therefore a main body can be conveniently pushedinto the main body positioning clamps to be positioned and clamped; and a bearing mounting assembly and the fixing block assembling mechanism are arranged at the top and the bottom of the operation table respectively, so that a shell and the main body are fixed through a fixing block penetrating through a bearing after the bearing and the main body are arranged, the situation that during manual mounting, the rhythm is slowed, and then the production efficiency is reduced is avoided, and then personnel saving and production efficiency improving are facilitated.

Owner:沈富春

Clamping device with angle adjusting structure for assembling automobile key contact pieces

InactiveCN112207385AConvenient positioning and clampingImprove assembly efficiencyWelding/soldering/cutting articlesSortingAir pump

The invention discloses a clamping device with an angle adjusting structure for assembling automobile key contact pieces, and relates to the technical field of automobile key contact piece assembly. The clamping device specifically comprises an assembly frame, an assembly part structure and a voltage detection probe, a key placement disc is arranged inside the assembly frame, the assembly part structure is fixed in the middle of the top surface of the assembly frame, the middle of a small push rod is connected with the left end of a two-way air pump through a soft air pipe, rubber air holes are formed in the surfaces of the two sides of a push piece, a sliding groove is formed inside a clamping block, and the voltage detection probe is arranged inside the sliding groove. According to the clamping device with the angle adjusting structure for assembling the automobile key contact pieces, the contact pieces are accurately conveyed to the designated position in an automobile key while being adsorbed, voltage detection can be conducted on the assembled contact pieces, meanwhile, classified discharging and conveying can be conducted on defective assembling pieces and correctly-assembledassembling pieces in an angle adjusting mode, and qualified pieces and unqualified pieces are prevented from being conveyed in a mixed mode.

Owner:东莞市龙飞数控科技有限公司

An optical glass fixing base for easy installation

ActiveCN114047131BEasy to storeEasy to adsorb each otherPhase-affecting property measurementsRefractive power measurementStructural engineeringOptical glass

The invention discloses an easy-to-install optical glass fixing base, relates to the technical field of optical glass support devices, specifically a left base, a positioning block and an inner rod, the upper left part of the left base is provided with a connecting seat, and The middle part of the connecting seat is connected with a movable plate through a connecting bolt, the upper end of the movable plate is provided with a protective cover, and the middle part of the movable plate is connected with a horizontal plate, the upper end of the horizontal plate is provided with a foam pad, and the lower end of the horizontal plate A spring is connected through the spring seat, the positioning block is arranged on the upper right part of the left base, a supporting flange is provided on the bottom outside of the left base, and a large card slot is opened on the bottom right side of the left base, so The inner side of the large card slot is connected with a sleeve rod through the first connecting bolt, and the inner rod is arranged on the right end middle piece of the sleeve rod. The easy-to-install optical glass fixing base is provided with a horizontal plate and a spring, combined with the function of the positioning block, the movable plates on both sides are turned inward, which facilitates the positioning and clamping of the optical glass.

Owner:NANTONG RUISEN OPTICAL CO LTD

Automatic laying device for nonwoven fabric

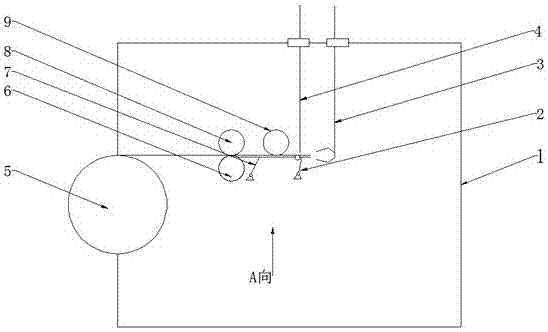

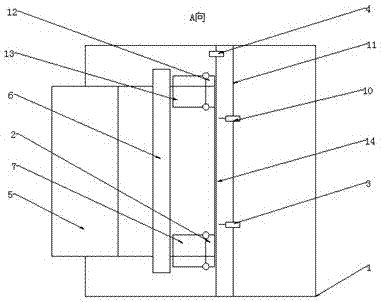

PendingCN107337022AAvoid insufficient clamping forcePriming guideLap forming devicesPackagingEngineeringManipulator

The invention provides an automatic laying device for nonwoven fabric. The automatic laying device comprises a nonwoven fabric lifting mechanism, a traction manipulator, a cutting manipulator, guiding rollers, guiding plates and the like. Through the identification of the width and diameter parameters of a hub, the nonwoven fabric lifting mechanism and the traction manipulator perform the height adjustment operation independently, and the traction manipulator performs the nonwoven fabric traction length adjustment operation. When the length of the nonwoven fabric is determined, the cutting manipulator performs the nonwoven fabric cutting operation, and then the nonwoven fabric is automatically laid.

Owner:CITIC DICASTAL

Quality detection equipment with sorting function for processing communication electronic parts

InactiveCN112222011AConvenient positioning and clampingEasy to useSortingStructural engineeringMechanical engineering

The invention discloses quality detection equipment with a sorting function for processing communication electronic parts, and relates to the technical field of electronic part processing. The qualitydetection equipment comprises a supporting column, a detection sensor and a sorting mechanism, a mounting frame is fixed above the supporting column, and a main conveying belt is arranged above the interior of the mounting frame. Limiting side plates are fixed to the two sides of the upper portion of the mounting frame correspondingly, side supporting boxes are arranged on the two sides of the outer portion of the mounting frame correspondingly, mounting bases are fixed to the upper portions of the side supporting boxes, racks are mounted above the mounting bases, display screens are fixed tothe upper portions of the racks, fixing rods are connected to the sides, close to the center line of the main conveying belt, below the racks, electric telescopic rods are installed on the bottom sides of the fixing rods, and positioning clamping mechanisms are fixed on the tops of the electric telescopic rods. The equipment has the advantages that the equipment can be separately arranged on thetwo sides of the outer portion of a part main body through two sets of symmetrical positioning blocks so that the part main body can be conveniently positioned and clamped.

Owner:东莞市帕特慕可科技有限公司

A tensile testing machine for testing the tensile degree of packaging bags

ActiveCN110672407BConvenient positioning and clampingImprove positioning and clamping stabilityMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesRatchetElectric machinery

The invention discloses a tensile testing machine for measuring the stretch degree of a packaging bag, comprising a base, a first motor, a pressure sensor, a second motor and a torque sensor. A bracket is fixedly connected to the top of the base, and the interior of the base is provided with a support. The liquid tank, the end of the output shaft of the first motor is coaxially connected with a screw rod, the top of the base is fixedly connected with a positioning tube, and the end of the positioning tube is provided with a positioning piece, and the support is provided with a rotating roller, The end of the rotating roller is fixed with a positioning plate, and the outer wall of the rotating rod in the positioning plate is provided with a ratchet, the second motor is fixedly installed at the top center of the bracket, and the end of the output shaft of the second motor is connected through the connection. The shaft is fixedly connected with one end of the cross bar. The tensile testing machine for the tensile degree detection of the packaging bag is convenient for positioning and clamping on both sides of the packaging bag, improving the positioning and clamping stability of the packaging bag, and the rotary tensile degree detection reduces the overall size of the device.

Owner:商丘市锦华包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com