Fast and accurate hoisting device and method for prefabricated stairs

A technology for hoisting devices and stairs, which is applied in the direction of transportation and packaging, load hanging components, cranes, etc. It can solve problems such as poor installation accuracy, difficult installation, and difficulty in precise positioning, so as to achieve smooth hoisting and subsequent installation processes and improve hoisting efficiency , Guarantee the effect of balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

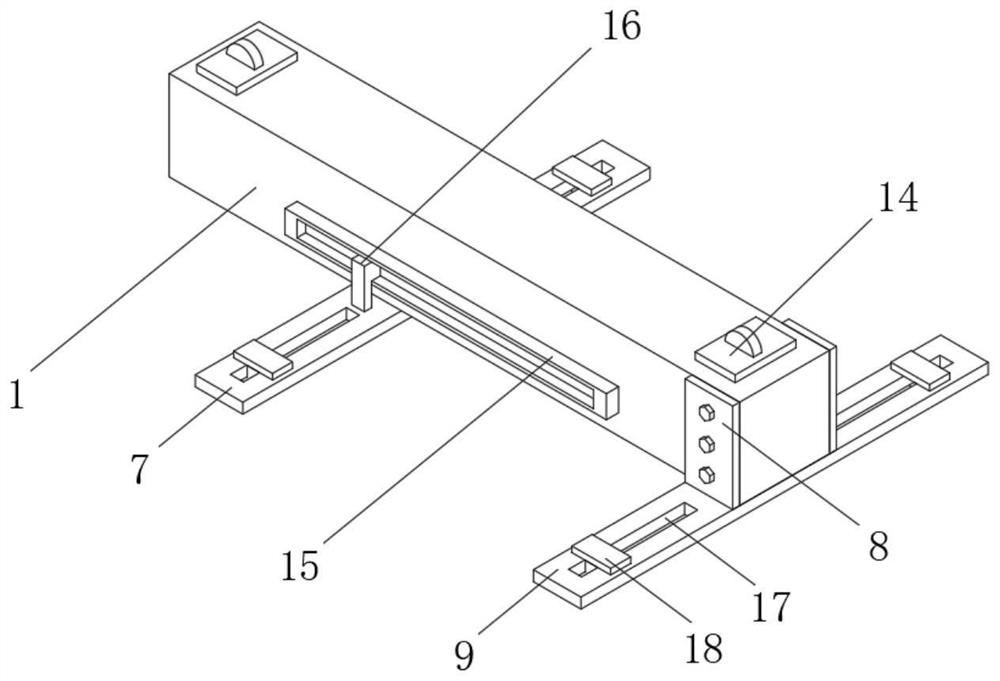

[0038] Such as Figure 1-5As shown, a fast and precise hoisting device for prefabricated stairs in this embodiment includes a box body 1 , a movable support 7 , a fixed support 9 , a positioning adjustment mechanism and a fixing mechanism 11 . Described box body 1 is processed into cuboid structure, and its inside is processed with inner chamber body, is used for installing positioning adjustment mechanism, and its top both sides is connected with suspension ring 14 (such as figure 1 As shown in , the two lifting rings 14 are symmetrically installed on the top of the box body 1 near the two ports), and the lifting rings 14 are processed into a U-shaped structure, made of stainless steel, and the setting of the lifting rings 14 facilitates the connection between the crane and the lifting device. Connect to facilitate the installation and disassembly of the hoisting device. The movable bracket 7 is installed on the positioning adjustment mechanism, and is slidably installed on ...

Embodiment 2

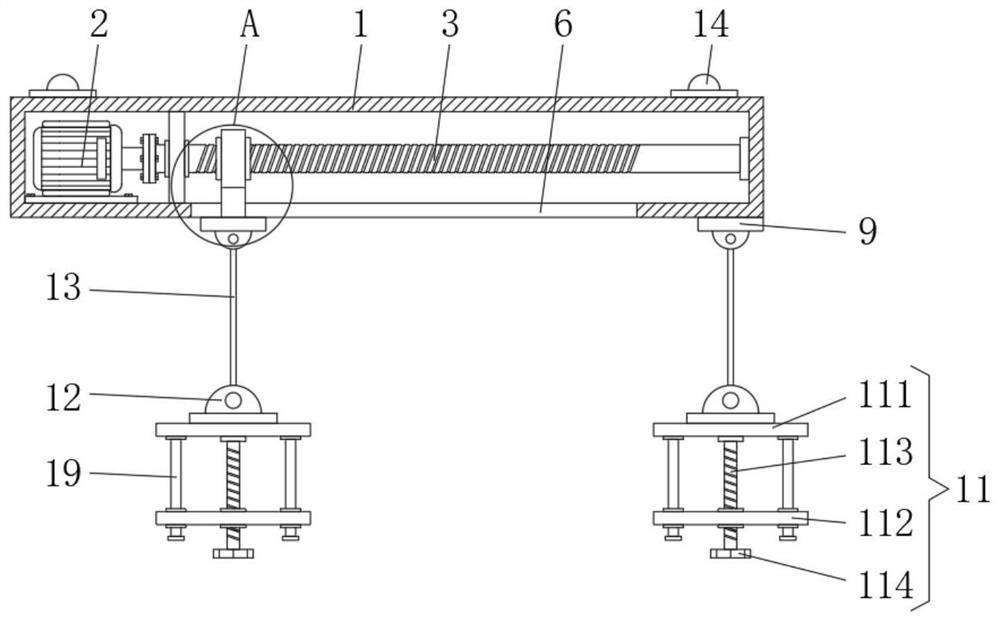

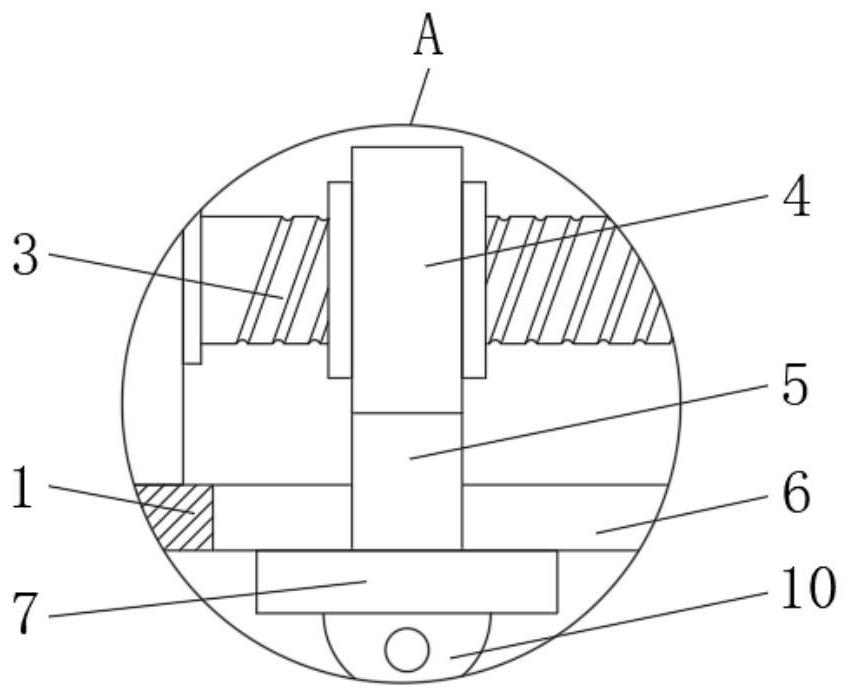

[0041] Such as Figure 1-5 As shown, a fast and precise hoisting device for prefabricated stairs in this embodiment, its main structure is basically the same as in Embodiment 1, the main difference is that the positioning adjustment mechanism includes a servo motor 2, a rotating shaft 3 and a positioning sleeve 4. Such as figure 1 and figure 2 As shown, the servo motor 2 is installed on the side of the inner cavity of the box body 1 away from the fixed bracket 9, the end of the output shaft of the servo motor 2 is provided with a partition, and the partition is processed with a through hole for the rotating shaft 3 to pass through. , A bearing seat is installed in the through hole. One end of the rotating shaft 3 passes through the partition and is connected with the output shaft of the servo motor 2, and the other end is also installed on the side wall of the casing 1 through a bearing seat, and the outer side of the rotating shaft 3 is provided with a positioning sleeve 4...

Embodiment 3

[0045] A fast and precise hoisting device for prefabricated stairs in this embodiment, its main structure is basically the same as in Embodiment 2, the main difference is that: Figure 1-3 As shown, the front and rear sides of the right end of the box body 1 are all bolted with mounting plates 8, the bottom of the mounting plate 8 is bolted with fixed brackets 9, and the bottoms of the movable brackets 7 and the fixed brackets 9 are located at both sides of the box body 1 and are provided with There is a first connecting seat 10 , a fixing mechanism 11 is arranged under the first connecting seat 10 , and a second connecting seat 12 is arranged on the top of the fixing mechanism 11 . A steel cable 13 is fixedly connected to the bottom of the first connecting seat 10 , and the bottom end of the steel cable 13 is fixedly connected to the second connecting seat 12 . The steel cable 13 is made of carbon steel wire, and the steel cable 13 is a three-twisted steel wire rope. The surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com