Tunnel piston effect mitigation device

A piston effect and tunnel technology, applied in mining equipment, tunnel systems, roads, etc., can solve problems such as easy generation of high-pressure waves, and achieve the effect of reducing the amount of reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

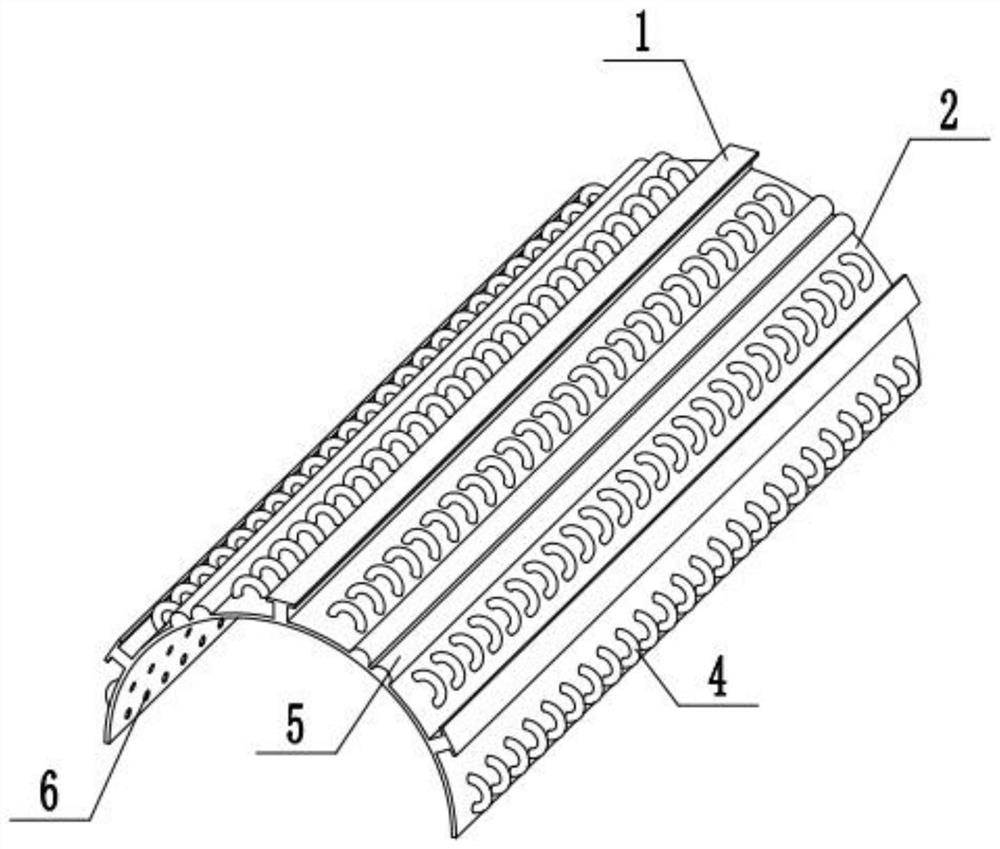

[0023] This embodiment is basically as figure 1 , figure 2 Shown:

[0024] Tunnel piston effect mitigation device, mounting components, several high-pressure wave absorbing components and several exhaust components.

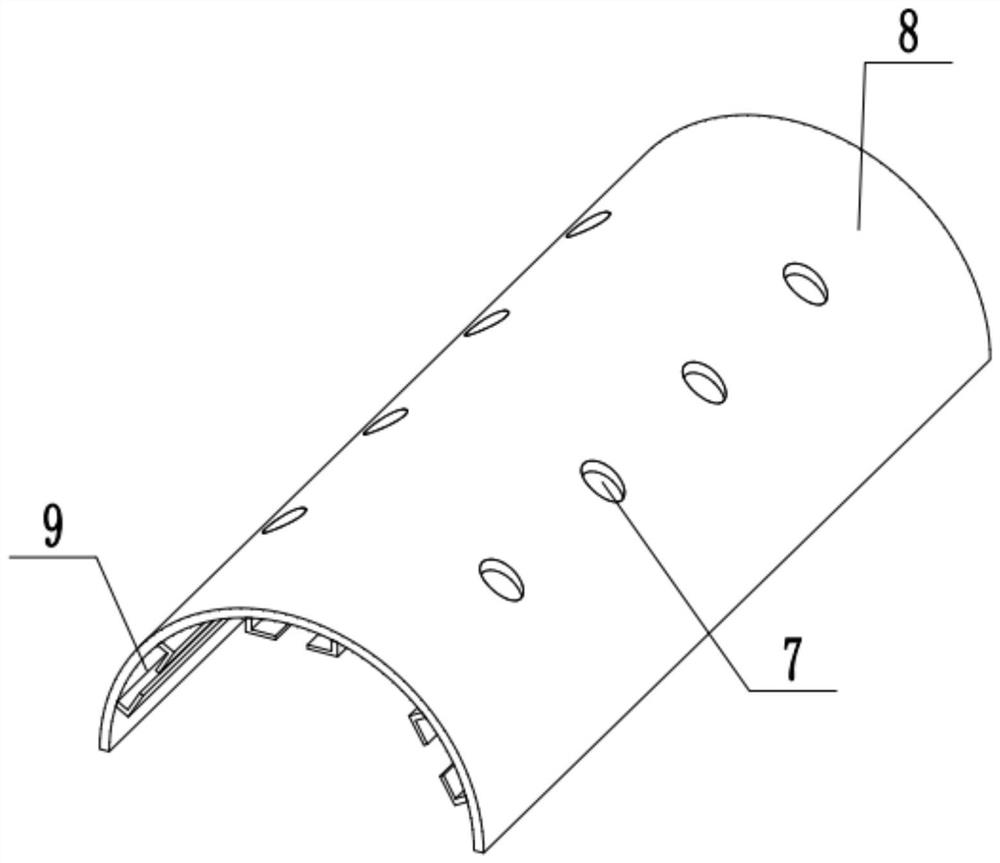

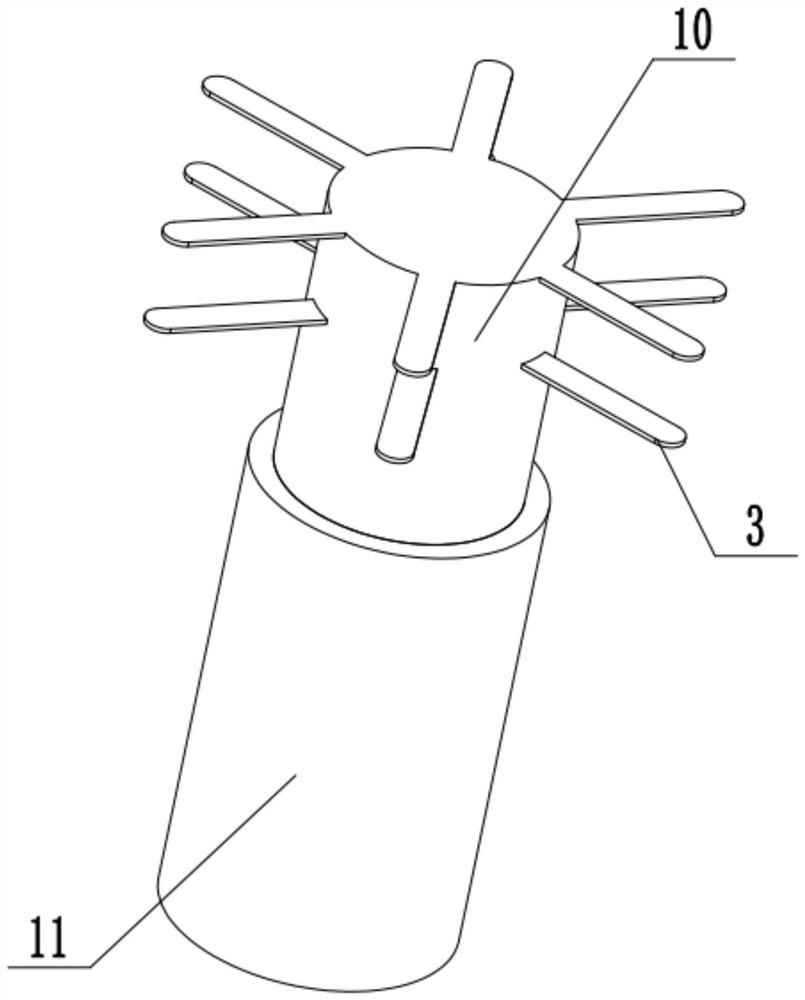

[0025] combine figure 2 , image 3 , according to the distance of the tunnel, select an appropriate number of embedded parts, before pouring the tunnel, wrap the connecting plate 3 on the embedded rod 10 on the structural steel bars of the reinforced tunnel to complete the fixing of the embedded parts, and then use concrete Pouring the prefabricated parts of the tunnel, and then installing the prefabricated parts on the inner wall of the newly opened tunnel. After the construction of the entire tunnel is completed, select the isolation cover 8 with a suitable length, and set up a number of positions corresponding to the number of embedded parts on the isolation cover 8. The connection holes 7 are then connected together with the connection sleeve 11 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com