Heat dissipation fin high in heat dissipation efficiency, of radiator

A technology of cooling fins and radiators, which is applied to heat exchange equipment, lighting and heating equipment, laminated components, etc. Air flow, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

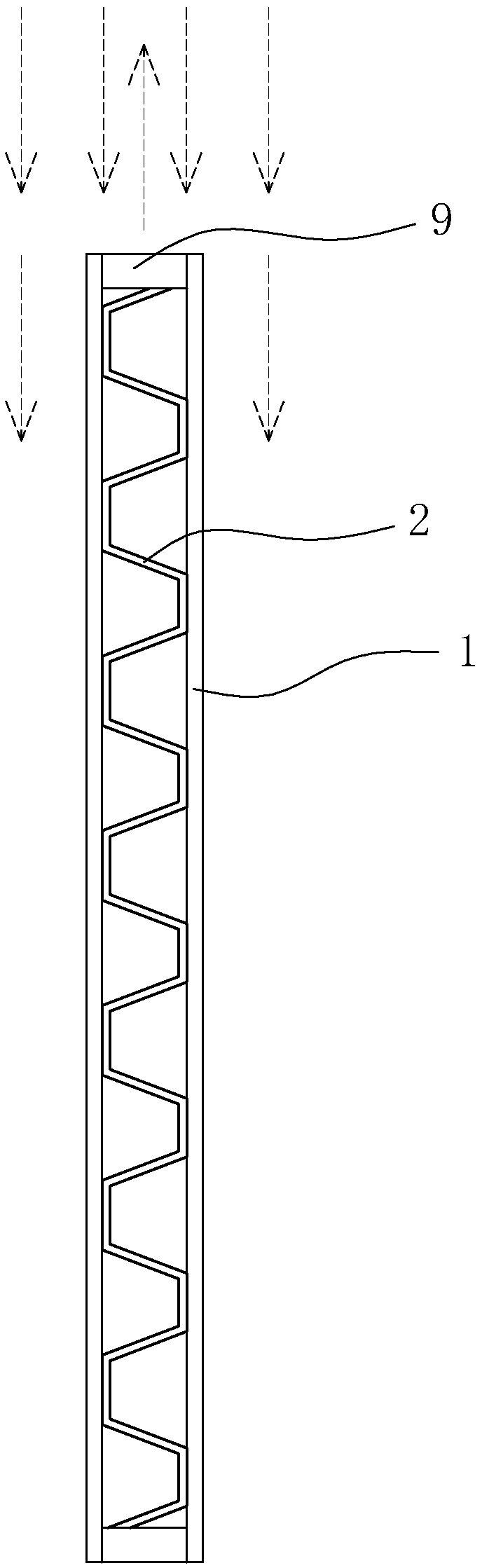

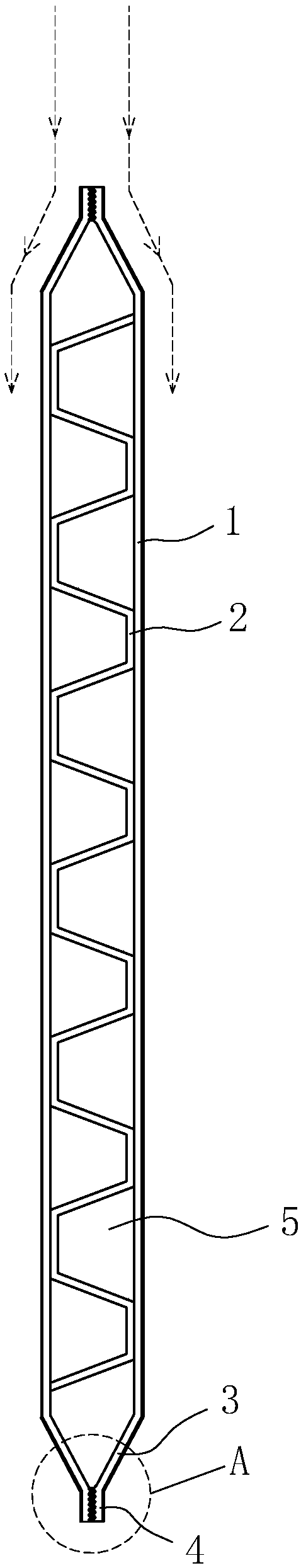

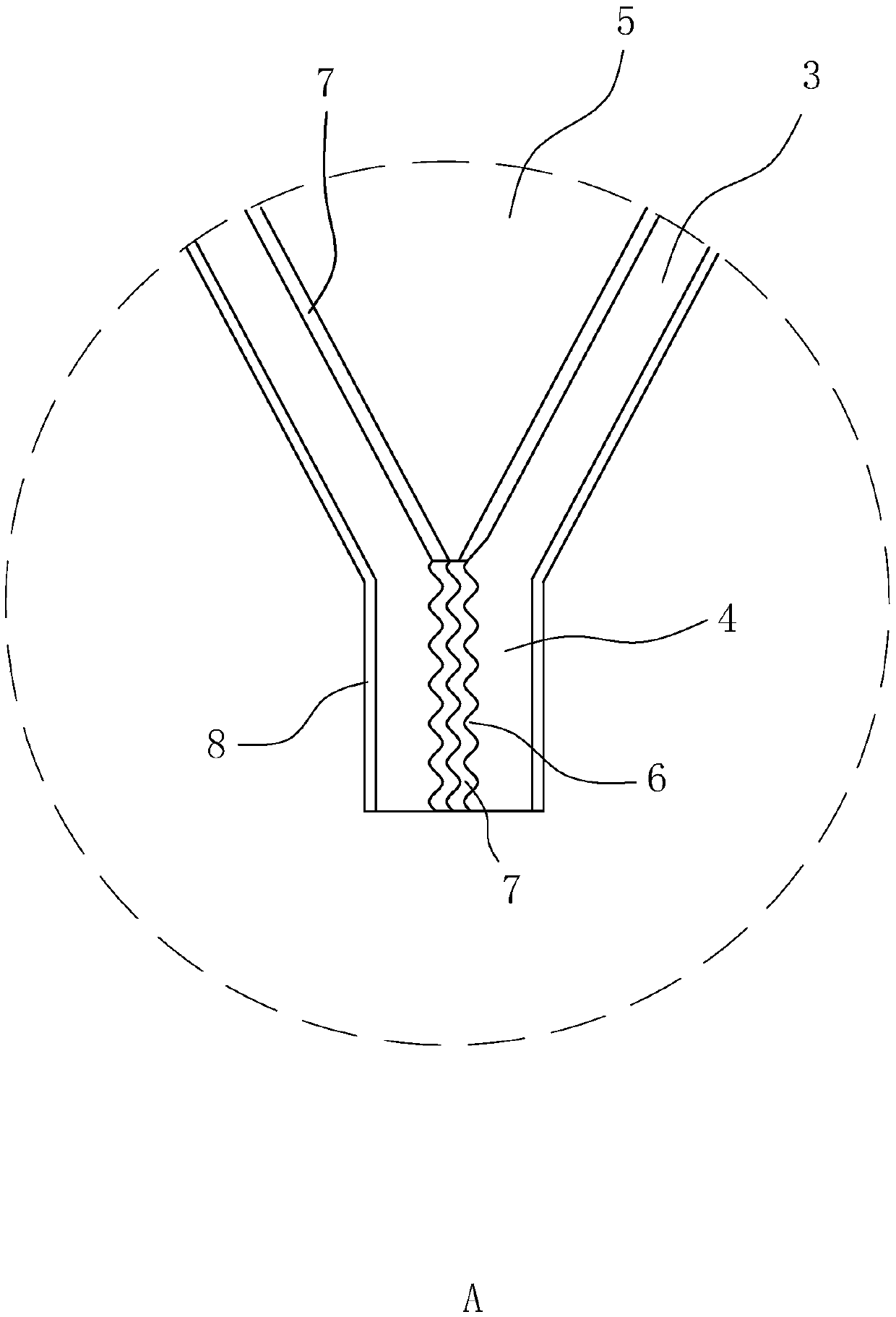

[0042] refer to figure 2 , a high-efficiency heat dissipation radiator fin, including a composite board 1 and an inner turbulent flow sheet 2, the composite board 1 is provided with two pieces, the composite board 1 is extended with drainage fins 3 on both sides, and the drainage fins 3 are facing away from There is a connecting piece 4 along the direction of the composite board 1; two composite boards 1 are symmetrically arranged, and the two composite boards 1 are connected to form a fluid channel 5, and the inner turbulent flow sheet 2 is arranged in the fluid channel 5, and the inner turbulent flow sheet 2 and the composite The plate 1 is fixedly connected; the composite plate 1, the drainage piece 3, the connecting piece 4 and the internal turbulence piece 2 are all made of 3003 aluminum alloy, the composite plate 1, the drainage piece 3 and the connecting piece 4 are integrally formed, and the aluminum alloy sheet is used to fold The 3003 aluminum alloy has better therm...

Embodiment 2

[0050] refer to Figure 4 , a high-efficiency heat dissipation radiator fin, the difference from Embodiment 1 is that the drain fin 3 is in an "S" shape, and the joints between the drain fin 3, the composite plate 1 and the connecting fin 4 are all smooth transition connections. When the vehicle is running, the airflow coming in front of the vehicle contacts the connecting piece 4 and then divides into two strands. Under the guidance of the drainage piece 3, it adheres to the drainage piece 3 and quickly flows to the composite board 1, bringing the heat on the composite board 1 to the composite board 1. Go; the guidance of the air-drain 3 reduces the rebound of the airflow, and because the air-drain 3 is streamlined, the speed of the airflow is faster, thereby improving the efficiency of air intake and heat dissipation.

Embodiment 3

[0052] refer to Figure 5 , a high-efficiency heat dissipation radiator fin, the difference from Example 1 is that: only one side of the composite board 1 is provided with a drain piece 3, and the drain piece 3 extends toward a direction away from the composite board 1 with a connecting piece 4; The composite board 1 is arranged symmetrically along the center, the connecting sheet 4 is directly bonded to the composite board 1 , and a solder layer 7 is provided on the side of the connecting sheet 4 facing the opposite composite board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com