Pavement slab capable of being laid on two sides

A road surface, double-sided technology, applied in the direction of roads, roads, pavement details, etc., to achieve the effect of improving resistance and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

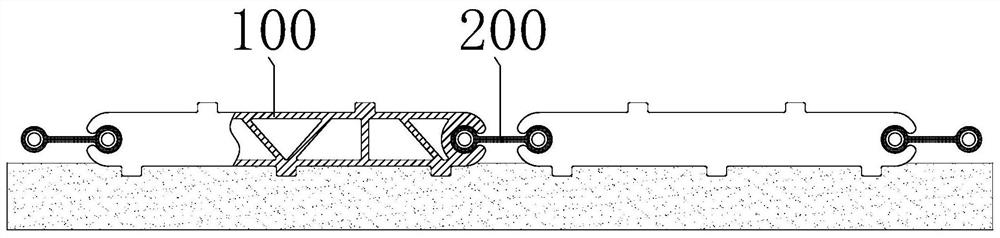

[0030] see figure 1 , the present invention provides a road slab that can be laid on both sides, including a road slab assembly 100 and a flexible connection assembly 200 .

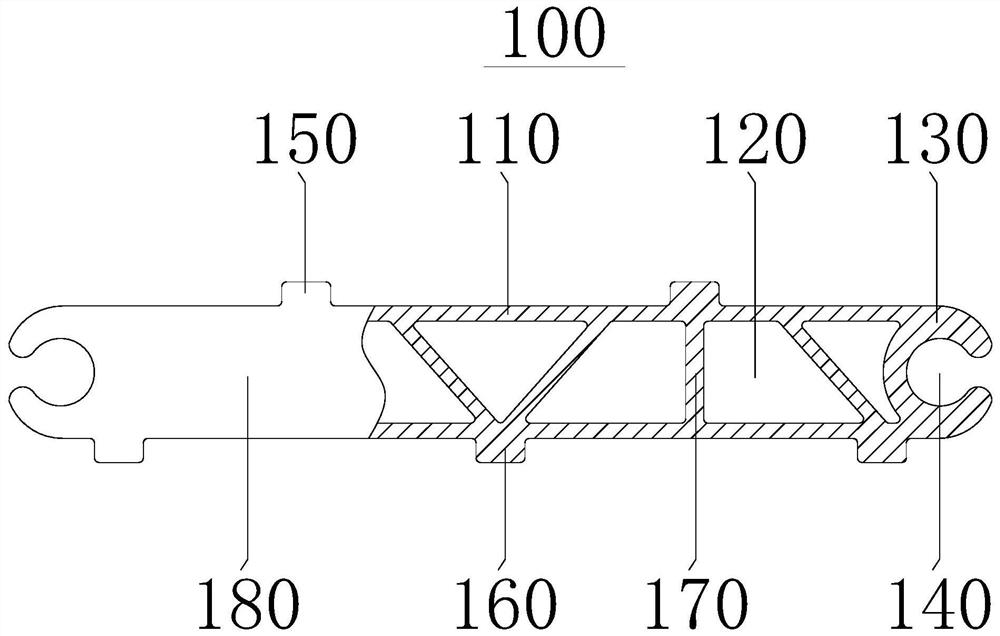

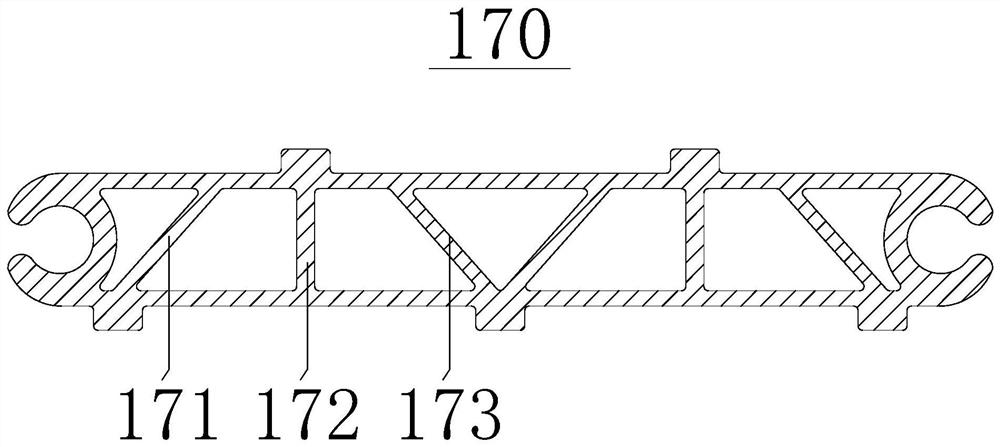

[0031] see figure 2 , the road panel assembly 100 is provided with several, the road panel assembly 100 includes a board body 110, a connecting clamp 130, a first anti-skid strip 150, a second anti-skid strip 160 and a reinforcing plate 170, and a cavity 120 is opened in the board body 110, Four connection clamps 130 are provided, and the four connection clamps 130 are fixedly connected to both sides of the two ends of the board body 110 respectively, wherein the connection clamps 130 and the board body 110 are formed by integral extrusion, and the corresponding connections at the two ends of the board body 110 A connecting cavity 140 is formed between the clamping plates 130, and the first anti-slip strip 150 and the second anti-slip strip 160 are fixedly connected to both sides of the plate body 110 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com