Discharge valve assembly and scroll compressor

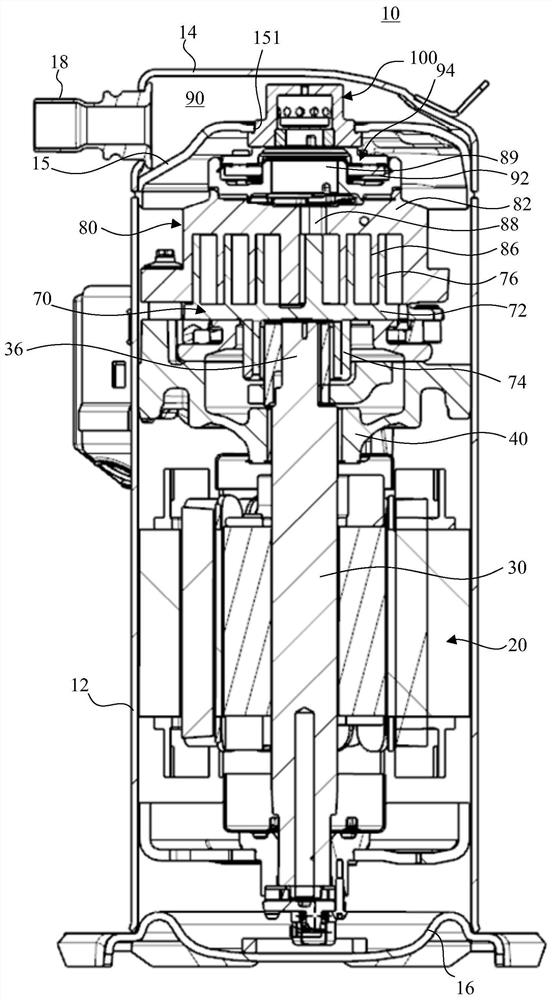

A scroll compressor, discharge valve technology, applied in the direction of rotary piston machinery, pump components, mechanical equipment, etc., to achieve the effect of improving the exhaust pressure relief function and shutdown function, with versatility, and improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following description of the preferred embodiments is exemplary only and in no way restricts the disclosure and its application or usage. The same or similar reference numerals are used to denote the same components in the respective drawings, and thus the configurations of the same components will not be described repeatedly.

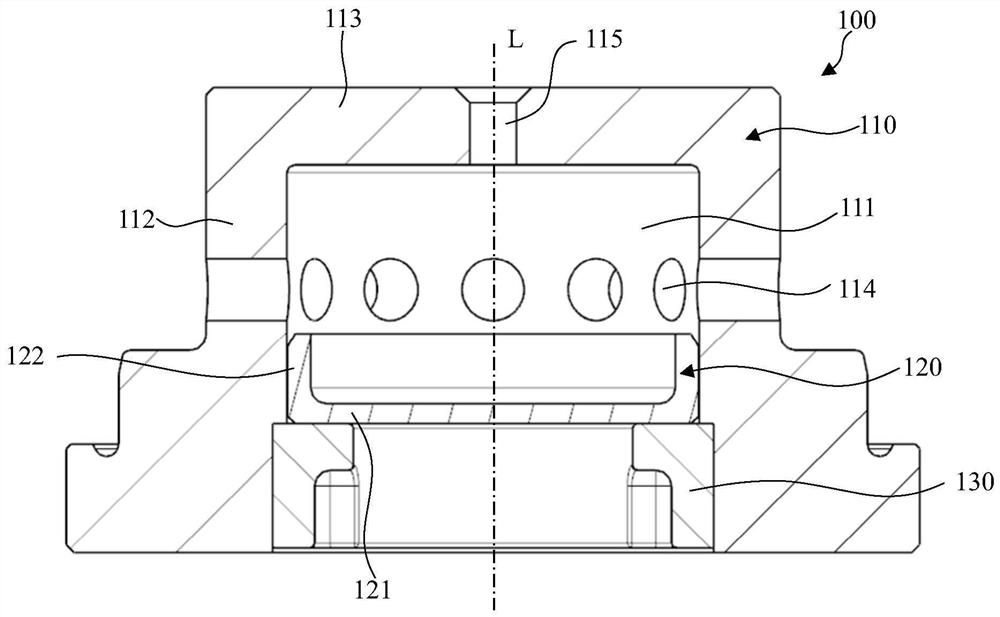

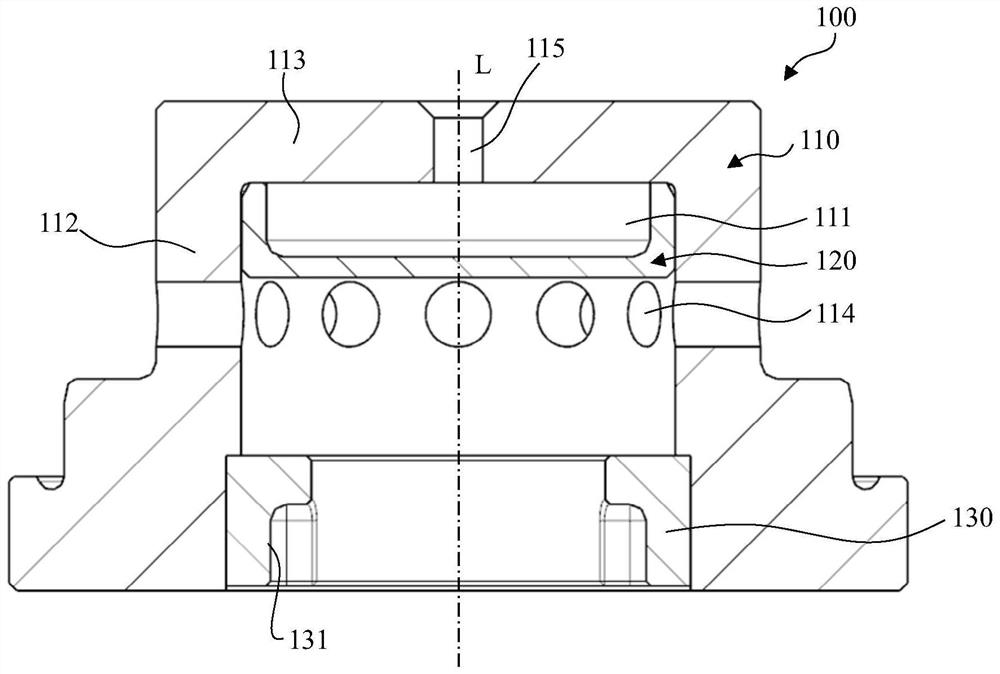

[0036] Although described herein in connection with a scroll compressor, a valve assembly according to the present disclosure is described. However, it will be appreciated that the valve assembly according to the present disclosure is not limited to scroll compressors, but can be applied to any other application requiring restriction of fluid flow. Furthermore, in the following description of the example embodiments, the valve assembly is installed at the central orifice of the diaphragm, however, depending on the location of the orifice (or referred to as the compression mechanism discharge hole) described below, according to the present di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap