A sensor rapid detection device

A detection device and sensor technology, which is applied in the field of sensor detection, can solve problems such as troublesome fixing and taking out of sensors, ground shattering, and affecting detection efficiency, so as to save trouble in fixing and taking out sensors, prevent shattering of the ground, and improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

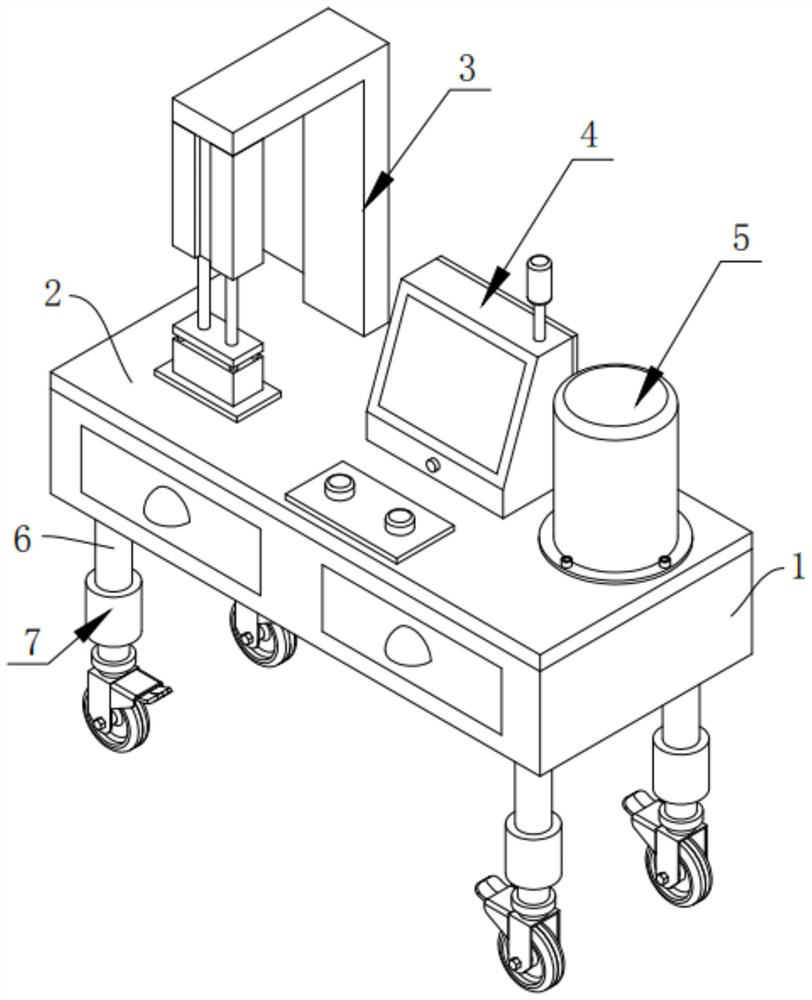

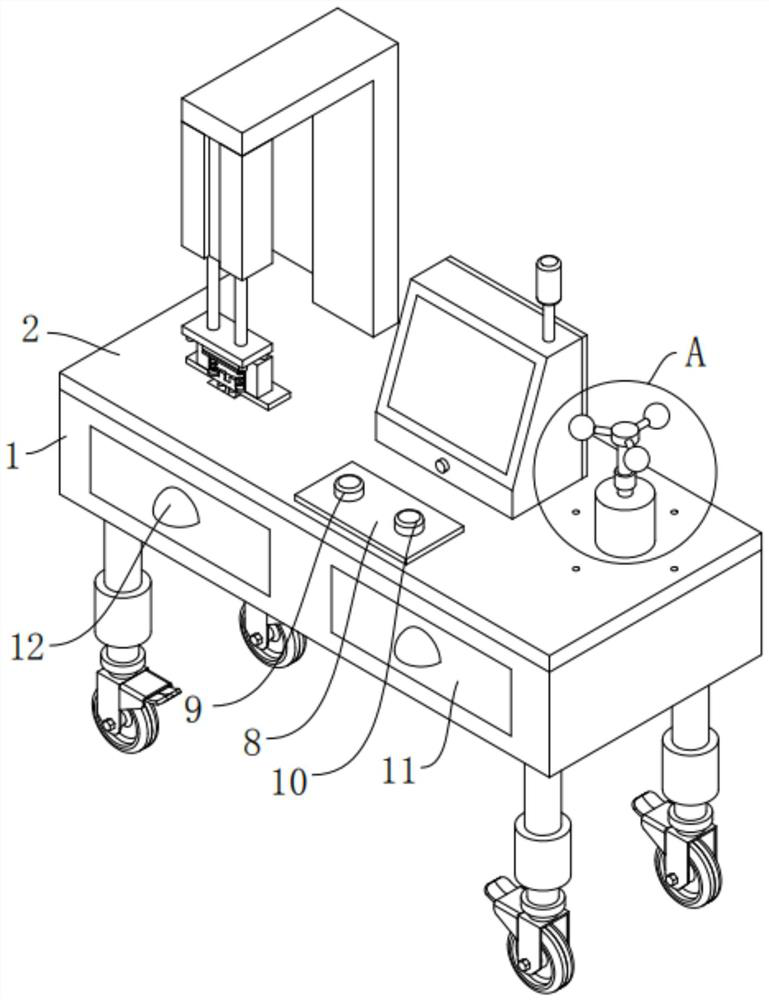

[0054] like Figure 1-Figure 3 As shown, a sensor rapid detection device according to an embodiment of the present invention includes a base 1, a station fixing mechanism 3, a parameter display mechanism 4 and an operation panel 8;

[0055] Among them, such as figure 1 As shown, the upper part of the base 1 is fixedly installed with a support plate 2, and the bottom of the base 1 is fixedly installed with four symmetrically arranged legs 6;

[0056] Among them, such as figure 1 , Figure 5-Figure 8 As shown, the station fixing mechanism 3 includes an L-shaped fixing frame 301, a telescopic cylinder 302, a fixing plate 303, a guide sleeve 306, two metal rods 310, a through groove 304, a supporting piece 307, a connecting plate 305, and a rubber pressing block 311 and four rubber blocks 312, the L-shaped fixed frame 301 is fixedly installed on the upper part of the support plate 2, and the telescopic cylinder 302 is vertically and fixedly installed at the bottom of the inner ...

Embodiment 2

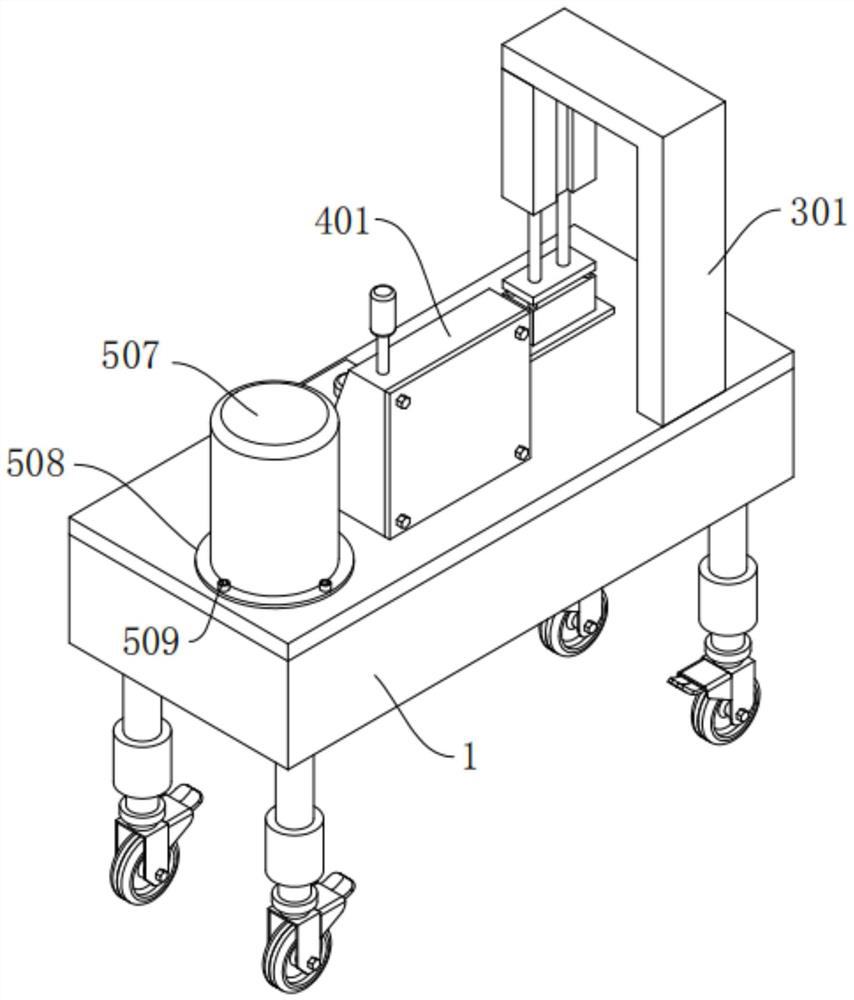

[0062] like Figure 1-Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that it also includes an actuator 5, and the actuator 5 includes a motor 501, a rotating shaft 502, an assembly block 503, three connecting rods 504, and three spherical blocks 505 and a cylindrical protective shell 507, the motor 501 is vertically and fixedly installed on the upper part of the support plate 2, the rotating shaft 502 is vertically arranged, and the bottom end of the rotating shaft 502 passes through a coupling 506 It is fixedly connected with the rotating shaft of the motor 501, the fitting block 503 is fixedly mounted on the upper end of the rotating shaft 502, and the three connecting rods 504 are fixedly mounted on the side of the fitting block 503 , and the three connecting rods 504 are arranged in a circumferential equiangular manner around the fitting block 503, and the three spherical blocks 505 are respectively fixedly installed on the ends of the three ...

Embodiment 3

[0065] like image 3 As shown, the difference between this embodiment and Embodiment 2 is that the inside of the base 1 is a hollow structure, and the front part of the base 1 is provided with two symmetrically arranged drawers 11, and the two drawers 11 Buckle hands 12 are all fixedly installed on the outer end faces.

[0066] By adopting the above technical solution, the drawer 11 can be used to store the unqualified sensors, which is convenient for the process personnel to analyze the problems of the unqualified sensors later, and facilitates the improvement of the process and the increase of the yield rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com