A Calculation Method of X-ray Residual Stress of α+β Type Titanium Alloy

A technology of residual stress and titanium alloy, applied in force/torque/work measuring instruments, measuring force, measuring devices, etc., can solve problems such as inability to obtain true and reliable residual stress measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

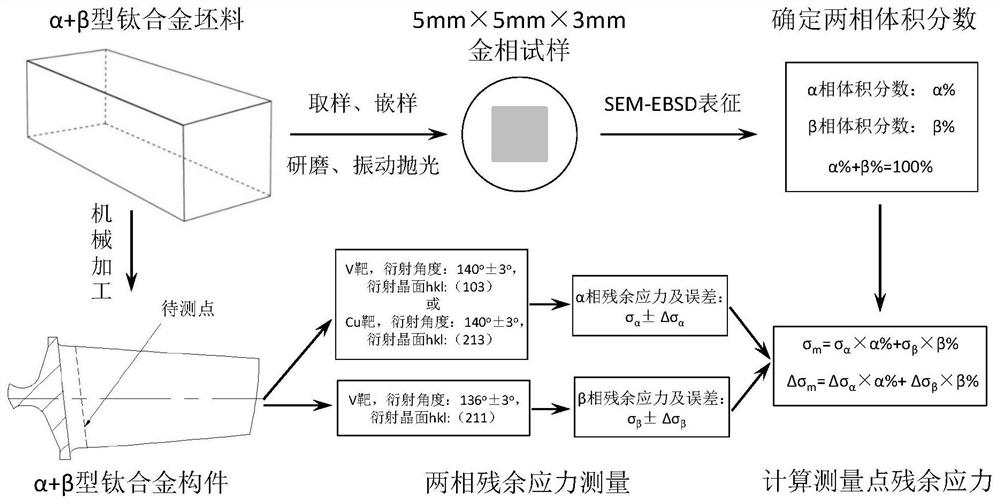

[0056] The TC17 titanium alloy blisk component used in an aero-engine has a nominal composition of Ti-5Al-2Sn-2Zr-4Mo-4Cr, and it is required to detect and evaluate the surface residual stress after machining.

[0057] In order to detect the residual stress at a measurement point of the TC17 titanium alloy blisk component, after the machining is completed, the following steps are carried out:

[0058] (1) Prepare a metallographic sample, the material taken is the same batch of blanks as the TC17 titanium alloy blisk component to be tested, and the size of the metallographic sample is 5mm×5mm×3mm;

[0059] (2) Embedding, grinding and vibrating polishing of metallographic samples;

[0060] (3) Scanning electron microscope-electron backscattering pattern technique (SEM-EBSD) is used to obtain the volume fraction of α phase in the metallographic sample: 27% and the volume fraction of β phase: 73%, 27%+73%=100 %,fulfil requirements;

[0061] (4) Place the TC17 titanium alloy blis...

Embodiment 2

[0073] A TC11 titanium alloy blade component used in an aero-engine has a nominal material composition of Ti-6.5Al-1.5Zr-3.5Mo-0.3Si. It is required to detect and evaluate the surface residual stress after the shot peening process is completed.

[0074] In order to detect the residual stress at a measurement point of the TC11 titanium alloy blade component, after the machining is completed, the following steps are carried out:

[0075] (1) Prepare a metallographic sample, the material taken is the same batch of blanks as the TC11 titanium alloy blade component to be tested, and the size of the metallographic sample is 5mm×5mm×3mm;

[0076] (2) Embedding, grinding and vibrating polishing of metallographic samples;

[0077] (3) Adopt scanning electron microscope-electron backscatter pattern technique (SEM-EBSD) to determine the volume fraction of α phase in the metallographic sample respectively: 68% and the volume fraction of β phase: 32%, 68%+32%=100 %,fulfil requirements;

...

Embodiment 3

[0090] A TC4 titanium alloy blade component used in an aero-engine has a nominal material composition of Ti-6Al-4V, and it is required to detect and evaluate the surface residual stress after the shot peening process is completed.

[0091] In order to detect the residual stress at a measurement point of the TC4 titanium alloy blade component, after the machining is completed, the following steps are carried out:

[0092] (1) Prepare a metallographic sample, the material taken is the same batch of blanks as the TC4 titanium alloy blade component to be tested, and the size of the metallographic sample is 5mm×5mm×3mm;

[0093] (2) Embedding, grinding and vibrating polishing of metallographic samples;

[0094] (3) Use scanning electron microscope-electron backscatter pattern technique (SEM-EBSD) to determine the volume fraction of α phase in the metallographic sample respectively: 40% and the volume fraction of β phase: 60%, 40%+60%=100 %,fulfil requirements;

[0095] (4) Place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com