Electric wrench

An electric wrench and moving cylinder technology, applied in the directions of wrenches, power tools, wrenches, etc., can solve the problems of large physical strength, rotation, reduction of equipment work efficiency and reliability, and achieve the effect of improving torque and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

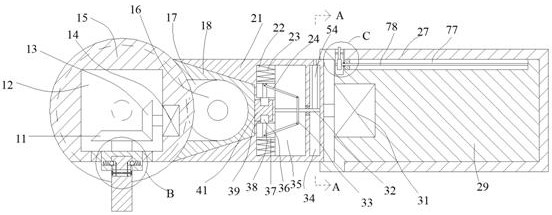

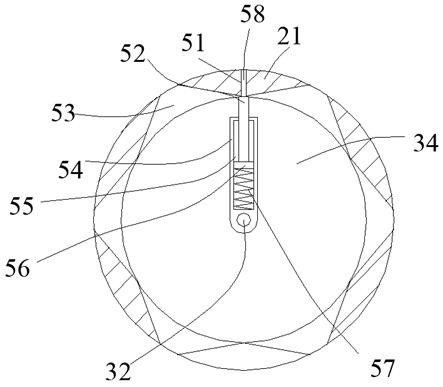

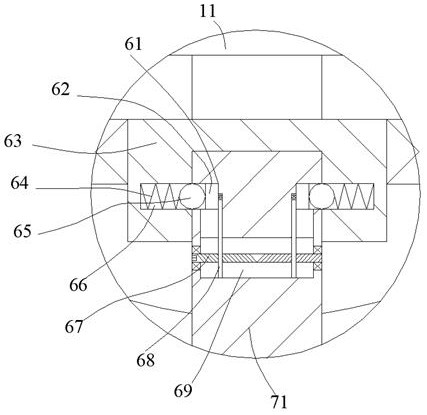

[0023]Such asFigure 1-Figure 4 As shown, the present invention will be described in detail. For the convenience of description, the following orientations are specified as follows:figure 1 The projection relationship is the same in the up, down, left, and right directions. The electric wrench of the present invention includes an intermediate barrel 29. The outer surface of the intermediate barrel 29 is slidably provided with an outer casing 27. An extension device for sliding between each other to extend the working length of the equipment is provided in the middle tube 29, an internal connection motor 31 is provided in the intermediate tube 29, and a side tube 21 is provided in the power connection on one side of the internal connection motor 31. The side tube 21 One side is provided with a rotating cylinder block 18, the rotating cylinder block 18 is provided with a motor-driven rotating disk 15 that rotates, and the rotating disk 15 is provided with a motor-driven screwing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com