Shoe film machine matched with PU synthetic leather shoe

A shoe film machine and synthetic leather technology, applied in the field of shoe film machines, can solve the problems of being easy to stick to other places or garbage, inconvenient to use next time, inconvenient to walk, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

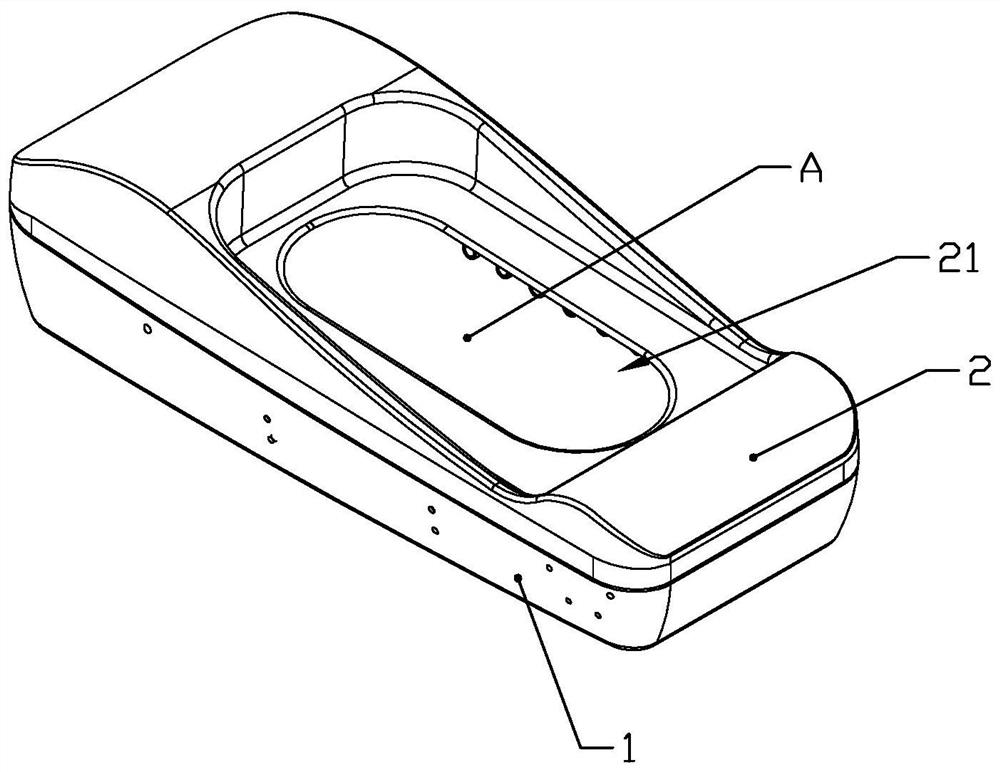

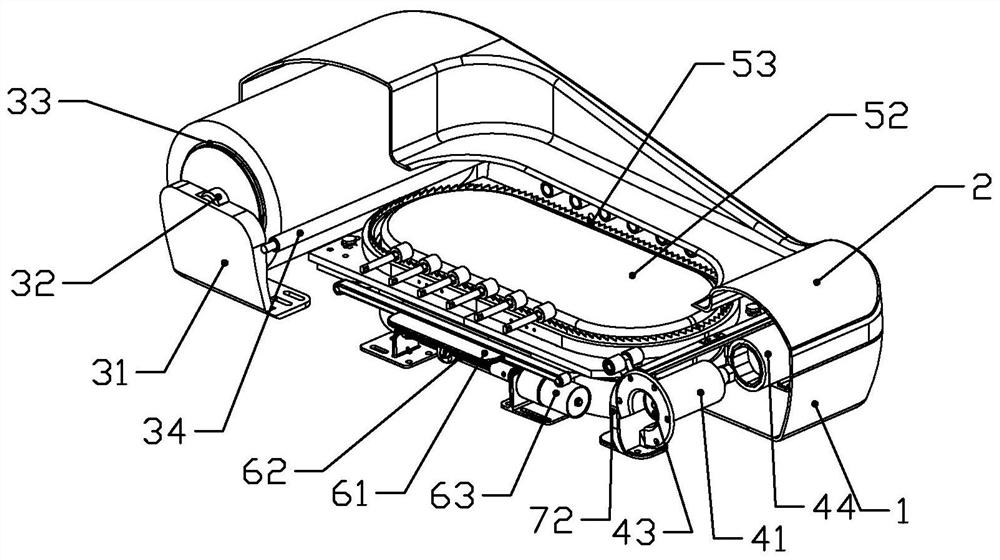

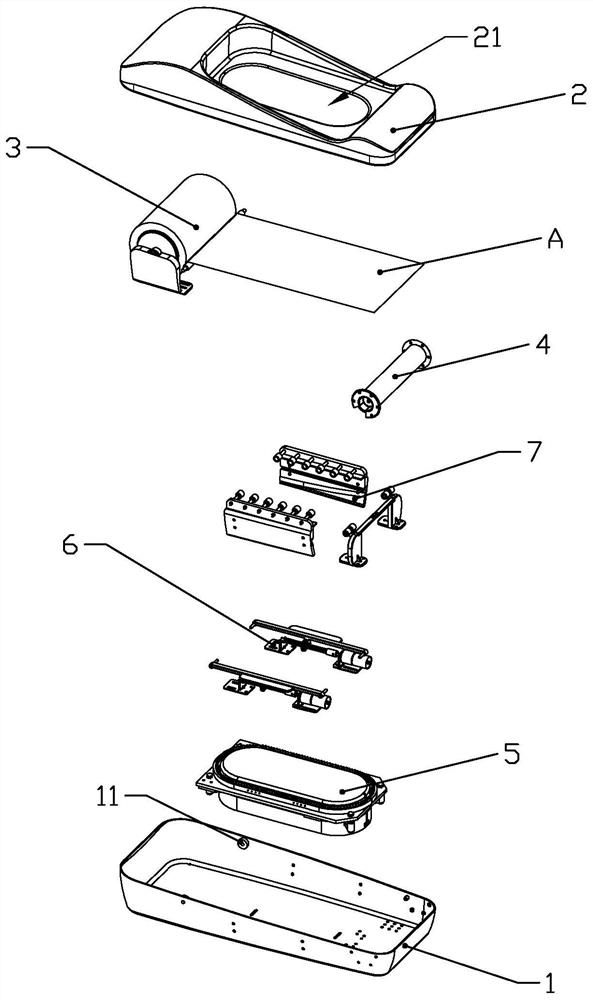

[0049] according to Figure 1 to Figure 12 As shown, a kind of shoe film machine that is equipped with PU synthetic leather shoes described in this embodiment includes a lower casing 1, a film release assembly 3 fixedly connected to the front part of the lower casing 1, and a film assembly fixedly connected to the lower casing 1. The film receiving assembly 4 at the rear of the lower housing 1; the inner bottom surface of the lower housing 1 is located between the film releasing assembly 3 and the film receiving assembly 4 and is fixedly connected with a film cutting assembly 5; The inner bottom surface of the casing 1 is located on the left and right sides of the film cutting assembly 5 and is respectively fixedly connected with symmetrically arranged driving assemblies 6; the driving assembly 6 can enable the film cutting assembly 5 to cut the shoe film.

[0050] The film release assembly 3 includes a film release reel 33 that is rotatably connected in the lower housing 1; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com