Automatic feeding type new energy automobile production line

A new energy vehicle, automatic feeding technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of high use limitations, poor adaptability of skids, etc., to increase support stability, reduce use limitations, improve adjustment convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

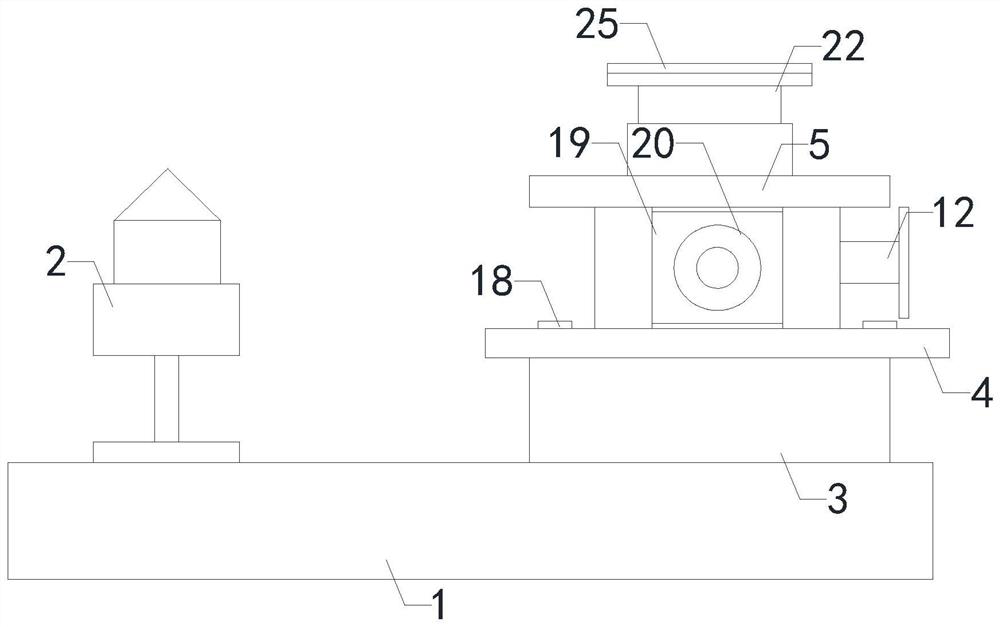

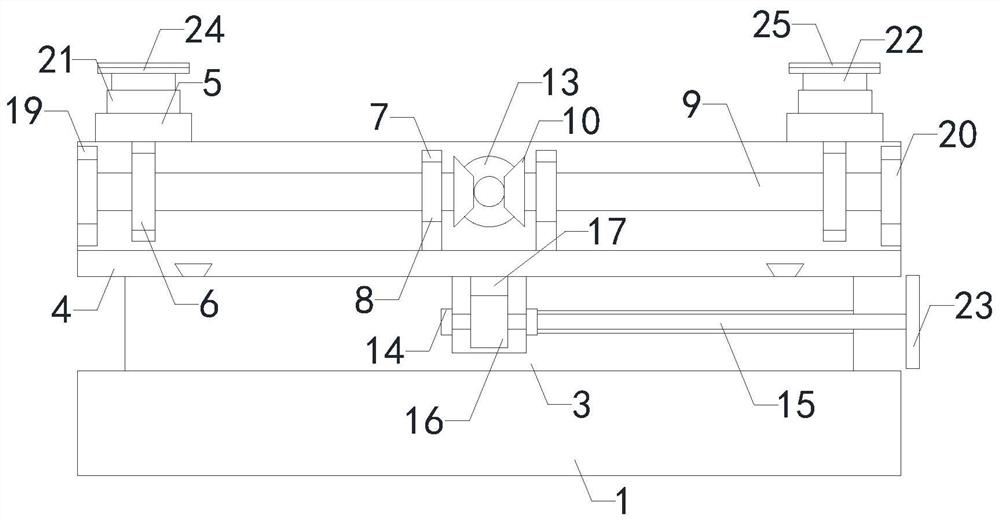

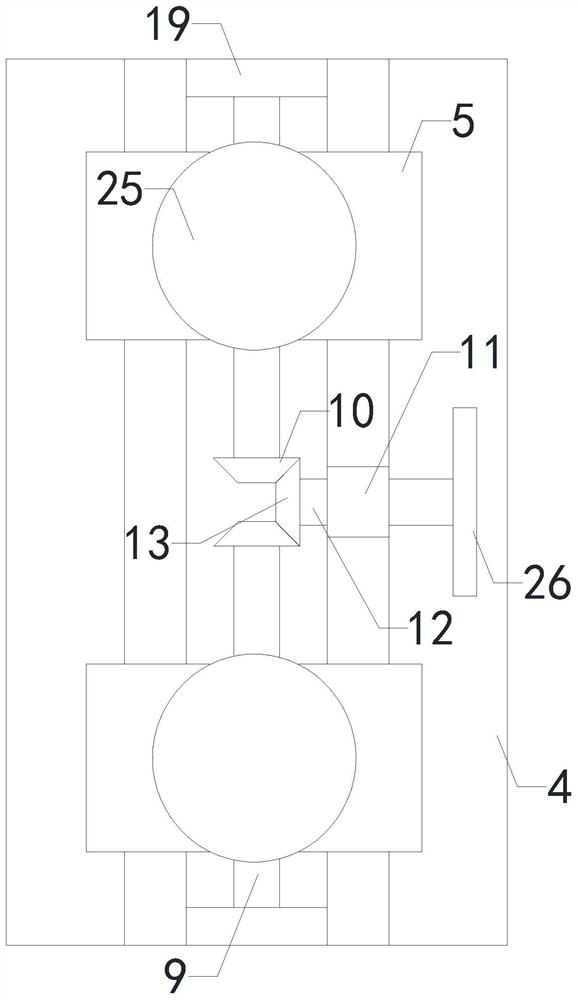

[0019] like Figure 1 to Figure 4 As shown, an automatic feeding type new energy automobile production line of the present invention includes a skid body 1, a front fulcrum 2, a first support frame 3, a second support frame 4, a rear bracket 5, a threaded sleeve 6, and a connecting frame 7. The first bearing 8, the lead screw 9, the driven conical gear 10, the longitudinal adjustment shaft 12 and the driving bevel gear 13, the bottom end of the front fulcrum 2 is installed on the left side of the top of the skid body 1, and the first support frame 3 The bottom end is installed on the right side of the top of the skid body 1, the bottom end of the second support frame 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com