Chemical fiber material processing winding device

A material processing and chemical fiber technology, applied in the field of fiber material processing, can solve the problems of troublesome disassembly and replacement of winding rollers, low replacement efficiency, and inability to make full use of resources, etc., and achieve the effect of improving winding efficiency and convenient disassembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

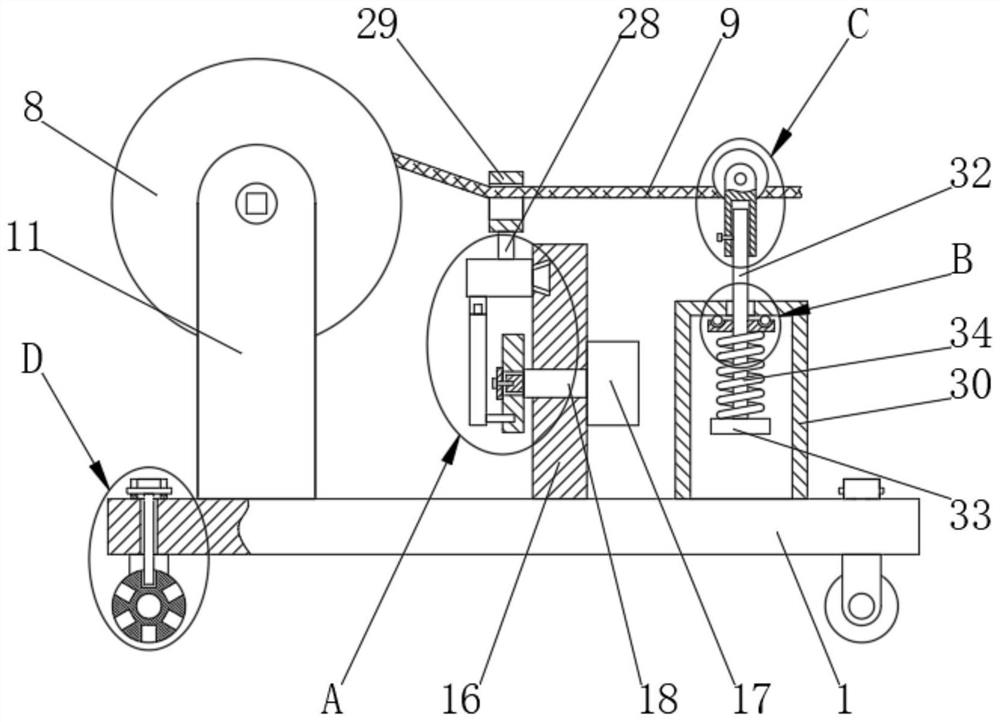

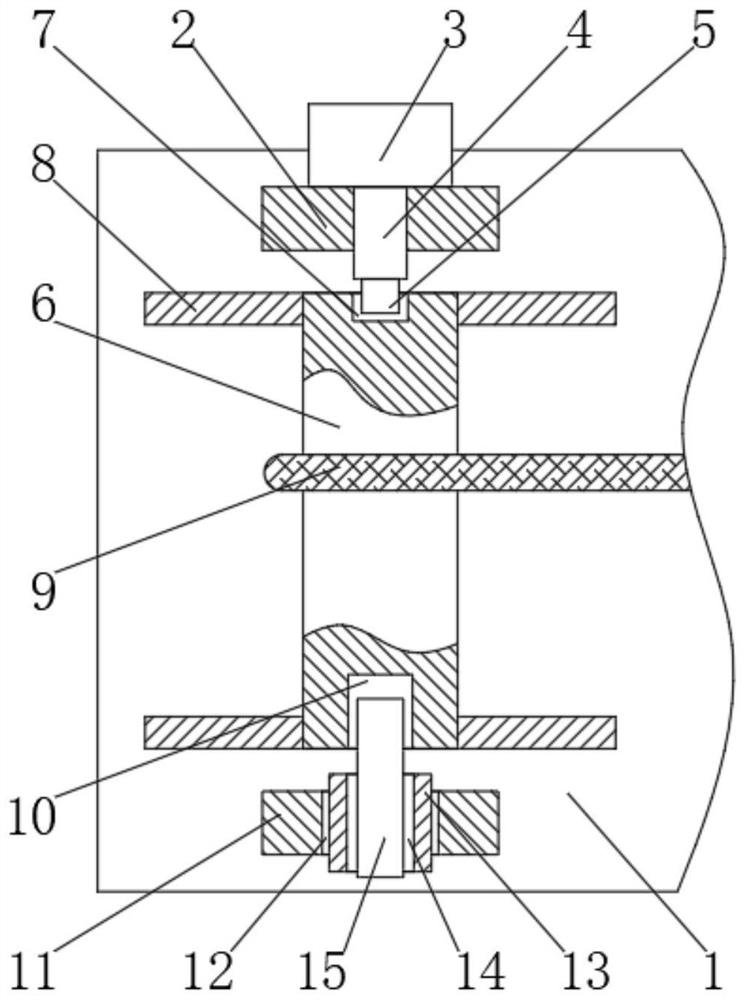

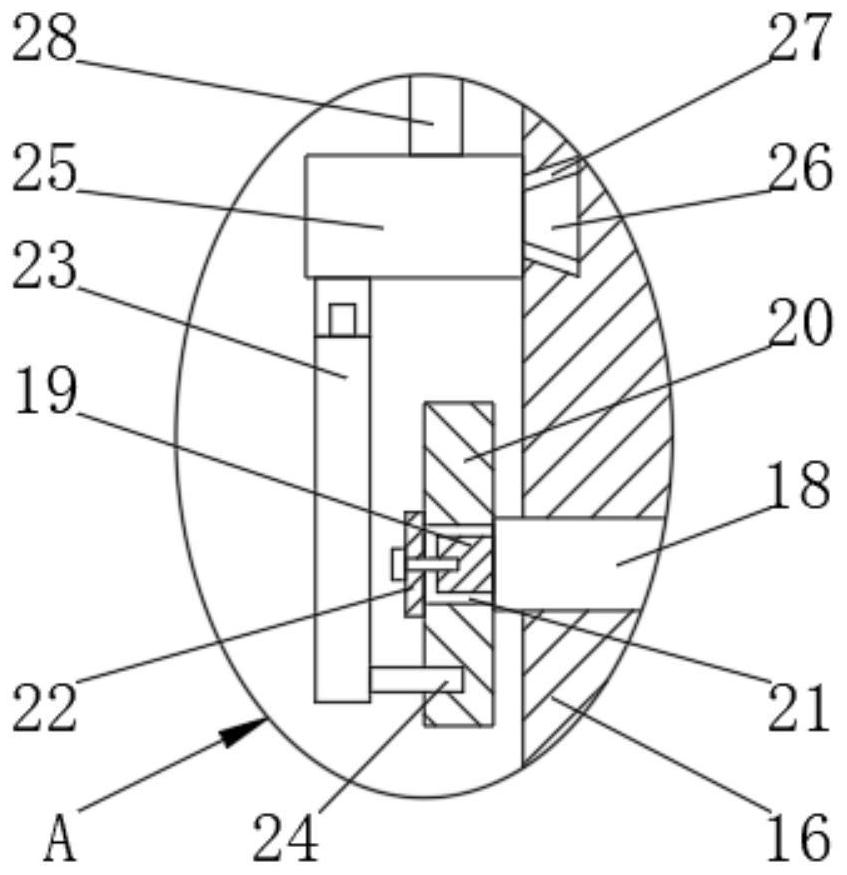

[0028] A winding device for processing chemical fiber materials, comprising a base plate 1, the upper end of the base plate 1 is welded with a rear support 2, the upper end of the base plate 1 is welded with a support plate 16, and the right end of the support plate 16 is fixedly installed with a second A motor 17, the left end of the second motor 17 is provided with a second rotating shaft 18, the second rotating shaft 18 is slidably sleeved in the support plate 16, the upper end of the base plate 1 is welded with a support frame 30, the base plate 1 The lower end is provided with a wheel 42, and the outer side of the wheel 42 is provided with a limiting groove 43, and the limiting pin 45 is slidably connected in the limiting groove 43, and a guide hole 44 is provided on the base plate 1, and a sliding hole 44 is provided in the guiding hole 44. The limit pin 45 is sleeved, the upper end of the limit pin 45 is welded with a cross bar 46, the upper end of the bottom plate 1 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap