Cabin entry method and cabin exit method for minimally invasive equipment for ship block

A technology for general section and equipment, which is applied in the field of minimally invasive equipment entering and exiting the ship's general section, which can solve the problems of large workload of assembly and welding, difficulty in lifting in and out, and damage to the hull structure, etc. problem, to achieve the effect of reducing workload, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

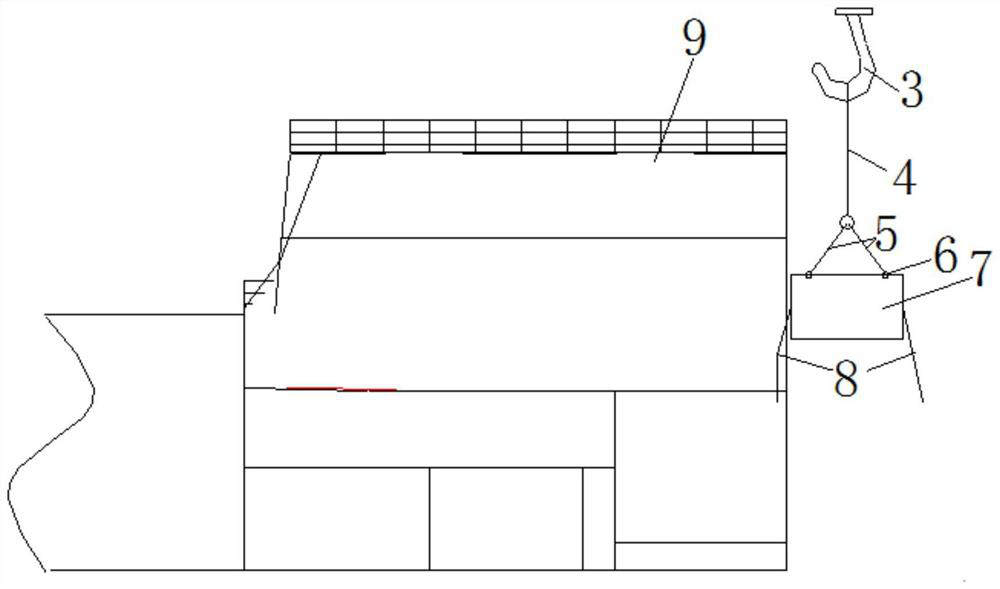

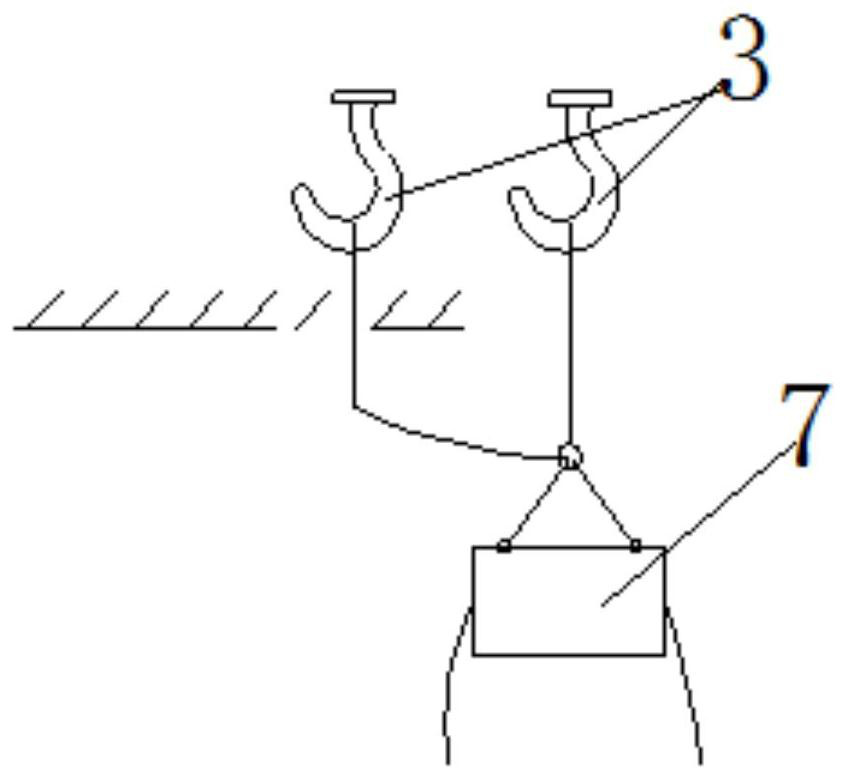

[0033] Such as Figure 1-Figure 6 As shown, this embodiment provides a method for entering the cabin of minimally invasive equipment in the general section of the ship, including the following steps:

[0034] Step 1. Open several hoisting round holes 9 at designated positions on the deck surface. The center line of several hoisting round holes 9 coincides with the centerline of the travel track of the equipment 7 to be hoisted, defining the hoisting from one side of the cabin to the other side. The round holes 9 are the first hoisting round hole to the Nth hoisting round hole, and the Nth hoisting round hole is located directly above the installation position of the equipment 7 to be hoisted. The diameter of the hoisting circular holes 9 is 300mm, and the distance between the centers of two adjacent hoisting circular holes 9 is 2-2.5m.

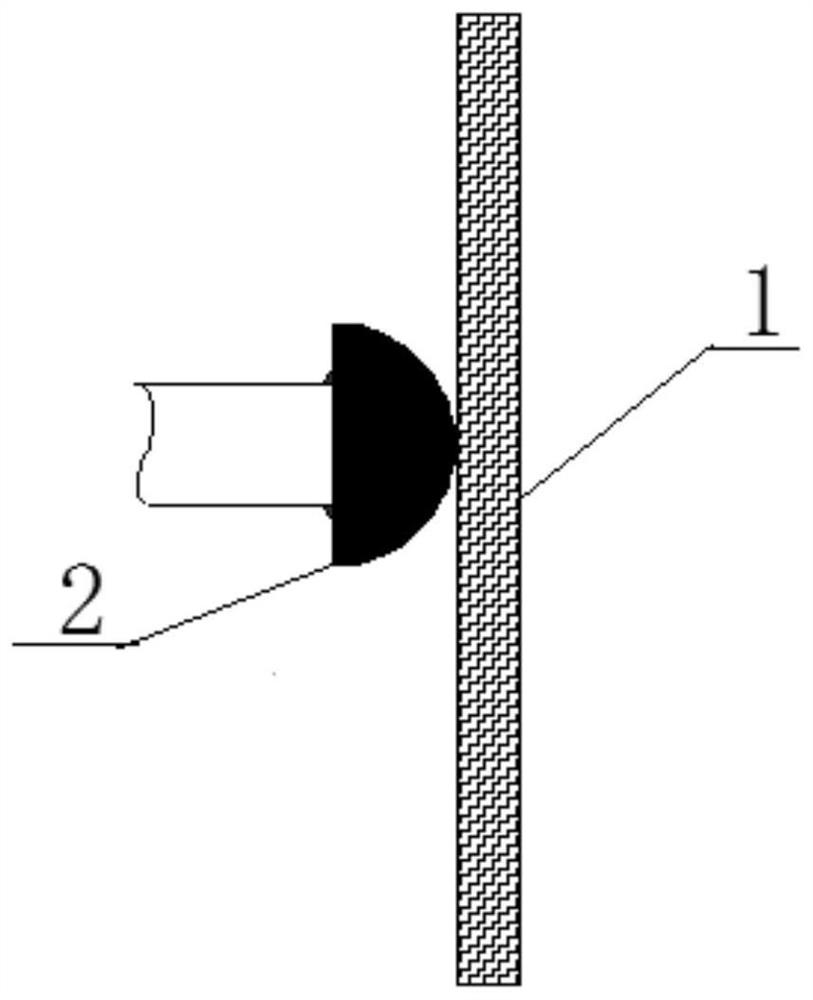

[0035] Step 2: Install semi-circular steel 2 on the edge of hoisting round hole 9, the arc surface of semi-circular steel 2 faces the center...

Embodiment 2

[0042] This embodiment provides a method for leaving the cabin of minimally invasive equipment in the general section of the ship. This method is the opposite of the hoisting process in Embodiment 1. The steps are as follows:

[0043]Step 1. Open several hoisting round holes 9 at designated positions on the deck surface. The center line of several hoisting round holes 9 coincides with the centerline of the travel track of the equipment 7 to be hoisted, defining the hoisting from one side of the cabin to the other side. The round holes 9 are the first hoisting round hole to the Nth hoisting round hole, and the Nth hoisting round hole is located directly above the installation position of the equipment 7 to be hoisted.

[0044] Step 2: Install a semi-circular steel 2 on the edge of the hoisting round hole 9, the arc surface of the semi-circular steel 2 faces the center of the hoisting round hole 9, and the semi-circular steel 2 and the edge of the hoisting round hole 9 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com