Biomass gasification automatic-control boiler

A biomass and boiler technology, applied in the field of hot water heating boilers, can solve the problems of complex operation and control mechanism and single applicable fuel, and achieve the effect of reducing the opening height and increasing the combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

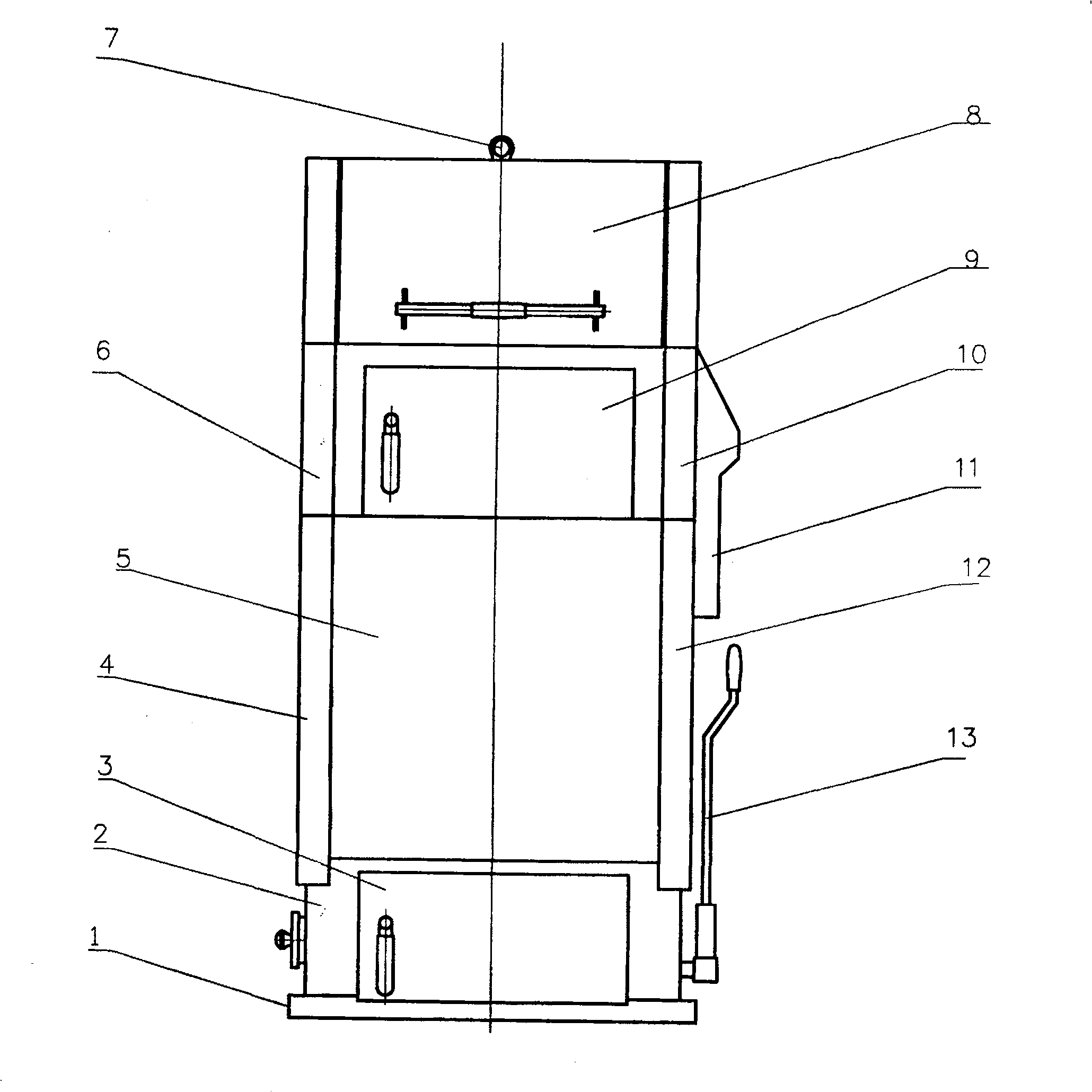

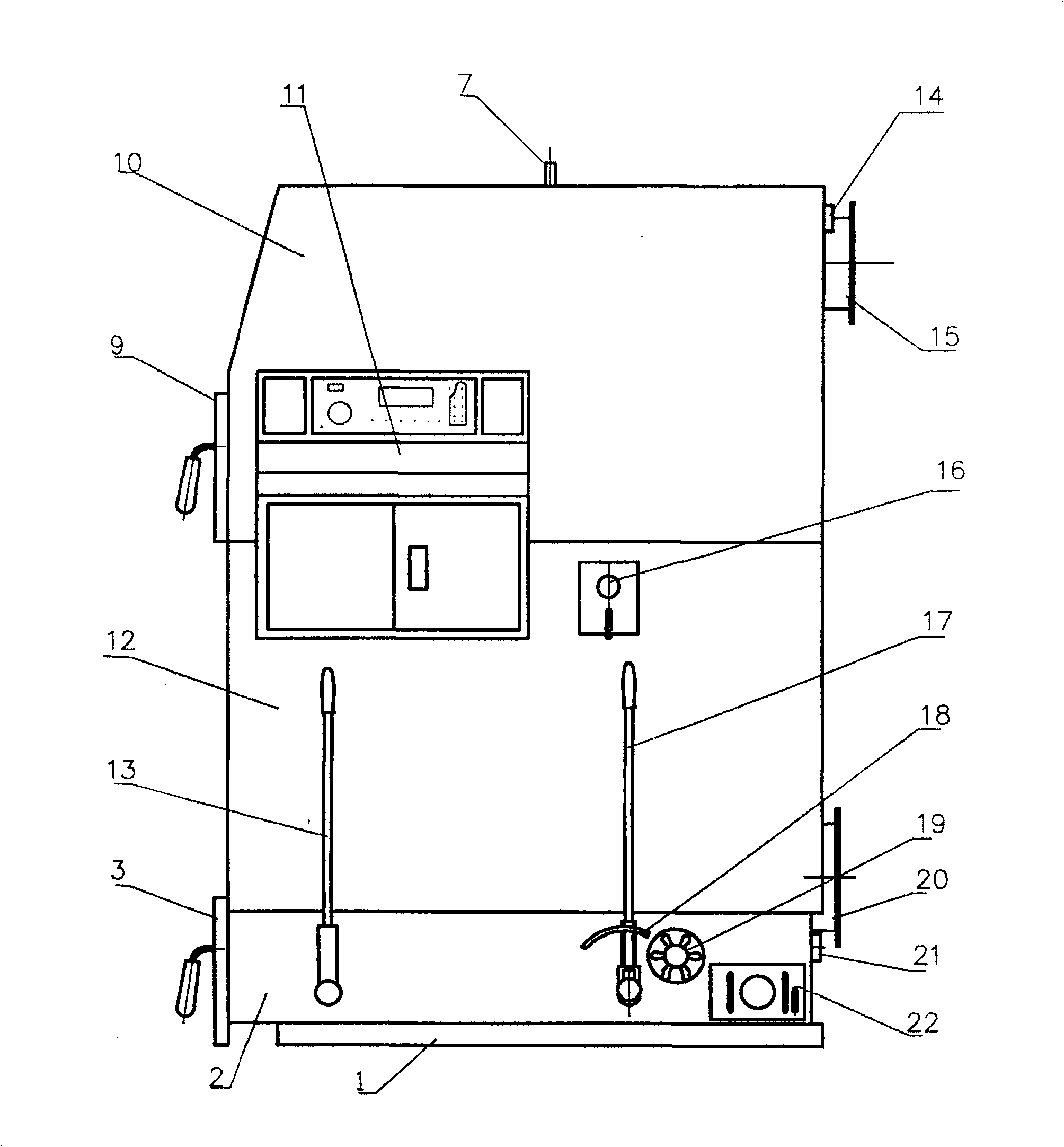

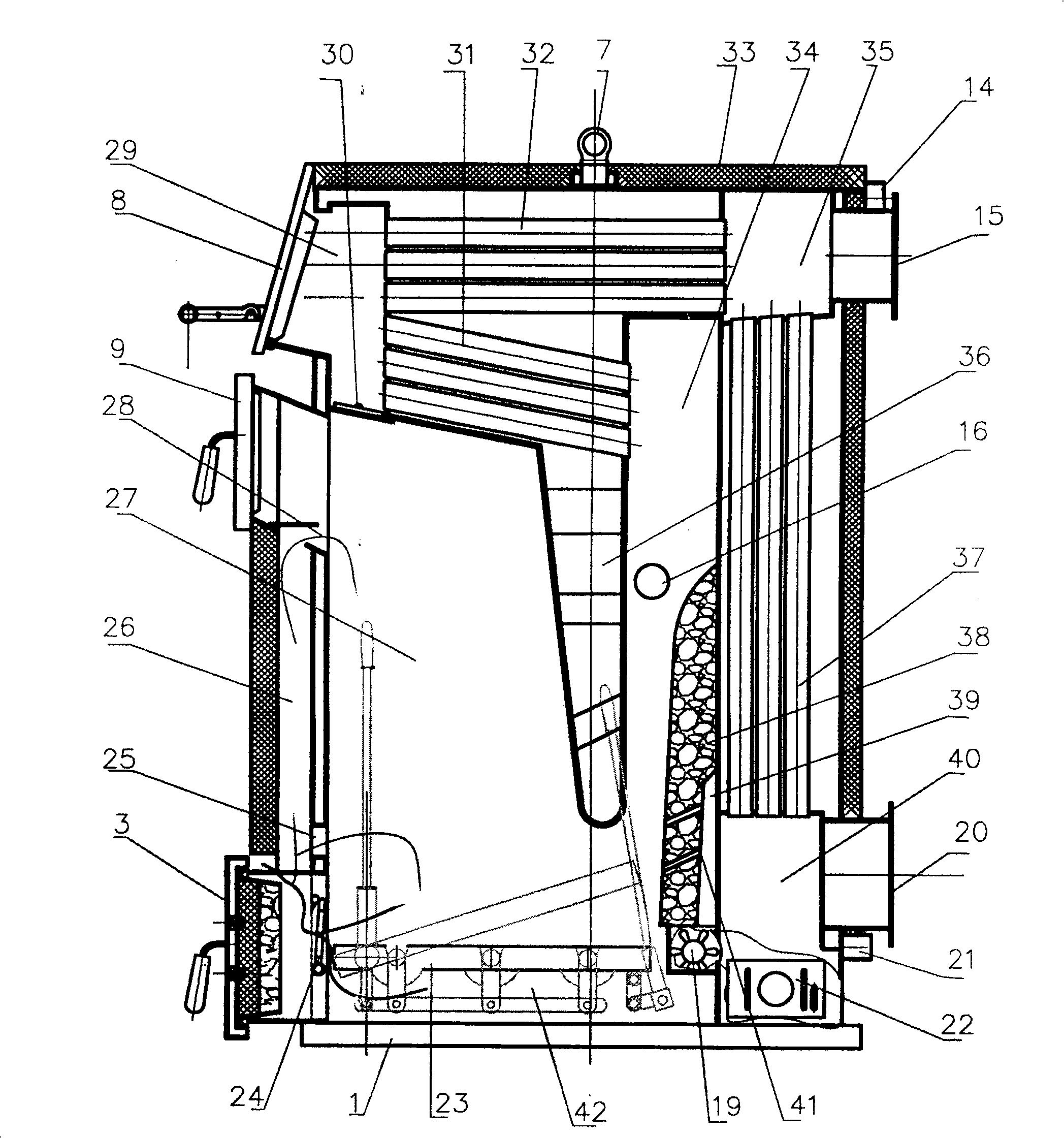

[0027] Such as figure 1 , figure 2 , image 3 Shown:

[0028]A circle of coaming 2 is welded around the top of the base 1. The front of the coaming 2 is an ash chamber 42. The front of the ash chamber 42 leads to the ash chamber door 3, and the ash removal grate is installed above the ash chamber 42. 23. Above the ash removal grate 23 is the furnace 27, and above the rear and upper part of the ash removal grate 23 is the secondary combustion chamber 34 adjacent to the furnace 27, separated by a fire baffle 36 with a sandwich structure in the middle, and the fire baffle There is a flue gas channel between the lower end of 36 and the ash removal grate 23, and the surrounding and top of the furnace 27, the fire baffle 36 and the secondary combustion chamber 34 are interconnected interlayer water jackets, which constitute the main body of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com