Dual-purpose pile driver for building pile foundation of constructional engineering

A technology of construction engineering and pile driver, which is applied in the field of dual-purpose pile driver, and can solve the problems of time-consuming and labor-intensive operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

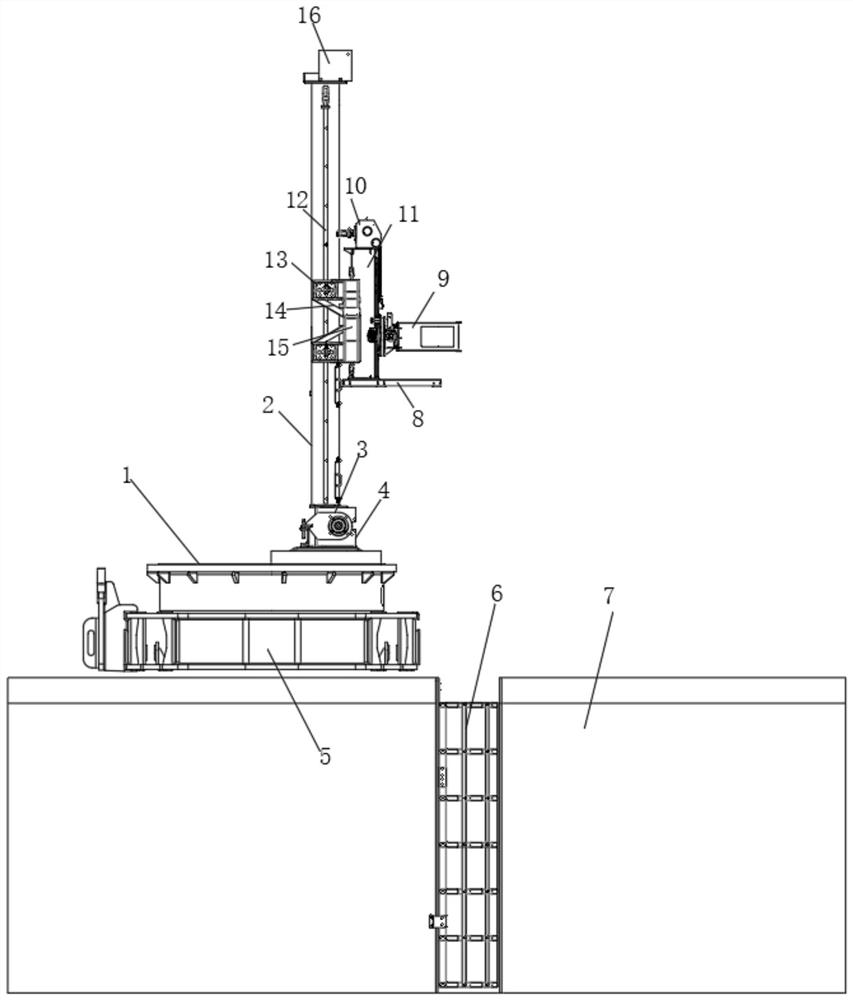

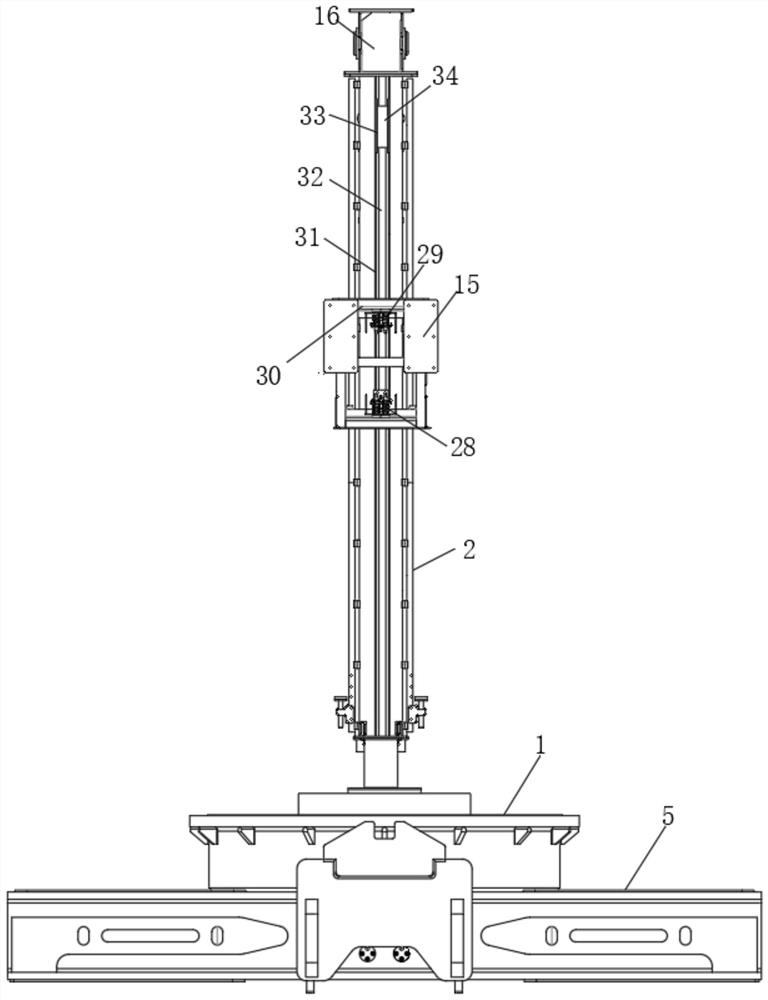

[0028] see Figure 1-7, the dual-purpose pile driver used for construction pile foundation construction in the embodiment of the present invention includes a pile driver 2, the bottom end of the pile driver 2 is provided with a mounting seat 4, and the lower surface of the mounting seat 4 is provided with a mounting cylinder 1. The lower part of the outer wall of the installation cylinder 1 is welded with an opening disc 61 , the outer wall of the opening disc 61 is welded with a base 5 , and the left and right walls of the base 5 are welded with a wheel body installation buckle 60 . The upper surface of the installation cylinder 1 is provided with a pair of perforations 62 , and the inner cavity wall of the pair of perforations 62 is welded with a perforated arched plate 63 . Threaded pillar 3 is installed on the outer wall of mounting seat 4, and one end of threaded pillar 3 runs through the left wall of mounting seat 4, and runs through the lower part of the outer wall of p...

Embodiment 2

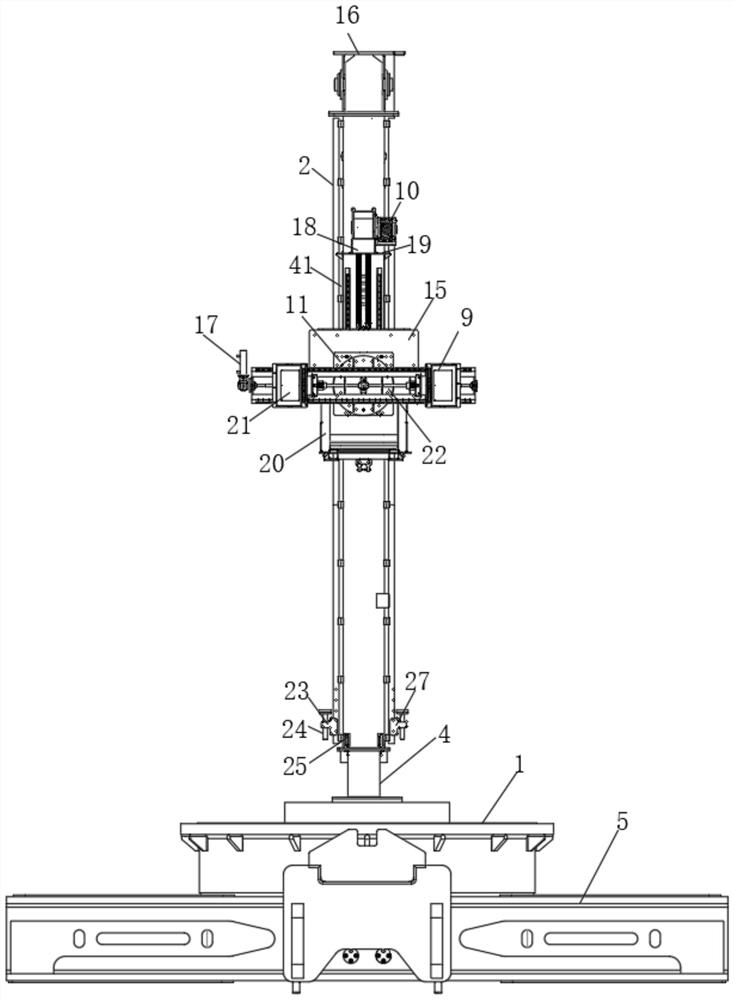

[0032] In a preferred embodiment, the left and right sides of the front elevation of the position-adjusting clamping tooling body 41 are welded with welding pieces 36, and the front side of the welding piece 36 is welded with welding rods 37. The chute opened on the side is slidingly connected, and the gear assembly box 18 is built-in with a gear assembly 42, and the outer wall of the gear is meshed with a chain 35, and a welding buckle 43 is installed between the two groups of chains 35. The bottom of the two groups of chains 35 The ends are welded with mounting buckles 38, and the fronts of two groups of mounting buckles 38 are fixedly connected with butt joint fixing blocks 40 by screws.

[0033] In a preferred embodiment, the lower part of the outer wall of the docking fixed block 40 is welded with a welding seat 39, the bottom end of the welding seat 39 is welded to the upper surface of the bottom plate 11, and a control box is installed on the outer wall of the position a...

Embodiment 3

[0035] In a preferred embodiment, the upper and lower parts of the front elevation of the transverse walking frame 45 are welded with a transverse slider body 59, and the left and right sides of the outer wall of the transverse slider body 59 are slidably connected with chute bottom blocks 58, and two groups of chute The front of the bottom block 58 is respectively welded with the second cylinder block 21 and the first cylinder block 9, the driving end of the second cylinder block 21 is equipped with a shaft, and a gear disc 52 is installed on the outer wall of the shaft bar, and the outer wall of the gear disc 52 engages There are mounting discs 55.

[0036] In a preferred embodiment, a rotating rod is installed at the center of the lower surface of the installation disk 55, and the bottom end of the rotation rod is connected to the right wall of the second cylinder block 21 in rotation, and a clip is installed on the front facade of the installation disk 55. Holding seat 57,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com