High-strength mining rock stratum migration grouting control and grouting amount calculation method

A grouting volume, high-strength technology, applied in ground mining, mining equipment, earthwork drilling and mining, etc., can solve the problems of large damage range of overlying strata, high degree of surface ecological damage, and large mining face size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An implementation of the present invention will be further described below in conjunction with accompanying drawing:

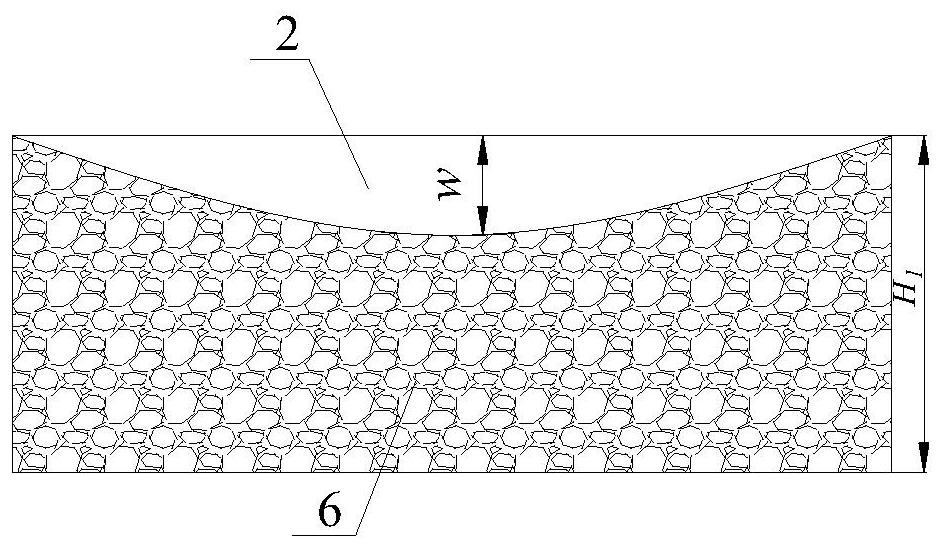

[0022] a. Calculate the position of the key layer 1 according to the drilling column diagram of the overlying rock, and calculate the height H1 of the caving zone 6 and the height H of the fracture zone 9 according to the mining height M of the coal seam 8 and the lithology of the roof 2 , the buried depth of coal seam 8 is H.

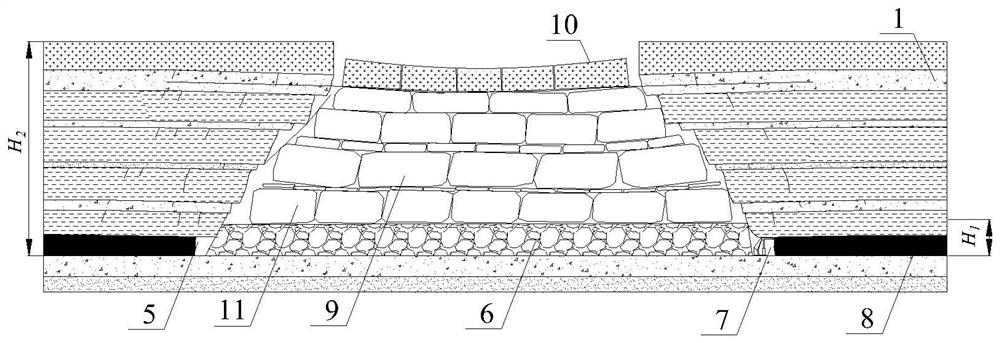

[0023] b. When H 2 When >H, the overlying rock is a "two-zone" development structure ( figure 1 ), it is necessary to carry out grouting in the caving zone 6;

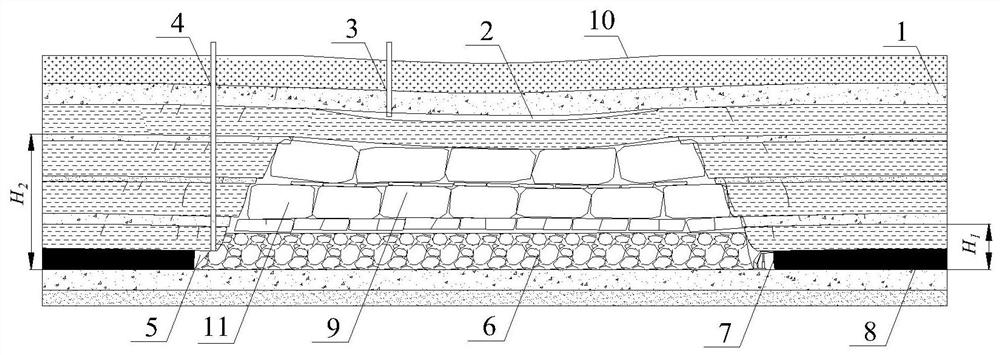

[0024] c. When H 2 When figure 2 ), there is no need to carry out grouting for the caving zone 6;

[0025] d. Drill the ground borehole 4 from the ground surface 10 to the caving zone 6, and the position of the ground drilling 4 in the caving zone 6 is directly above the middle part of the cutting hole 5 in the working face;

[0026] e. When the working face 7 adva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com