A self-duplex inclined shaft pressure relief and explosion-proof device and method for safe production in coal mines

A coal mine safety and explosion-proof device technology, applied in safety devices, mining devices, mine/tunnel ventilation, etc., can solve problems such as failure to reset correctly, air leakage from explosion-proof doors, endangering the safety of mine operators in ventilators and ventilation systems, etc., to achieve Guaranteed full availability and guaranteed life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

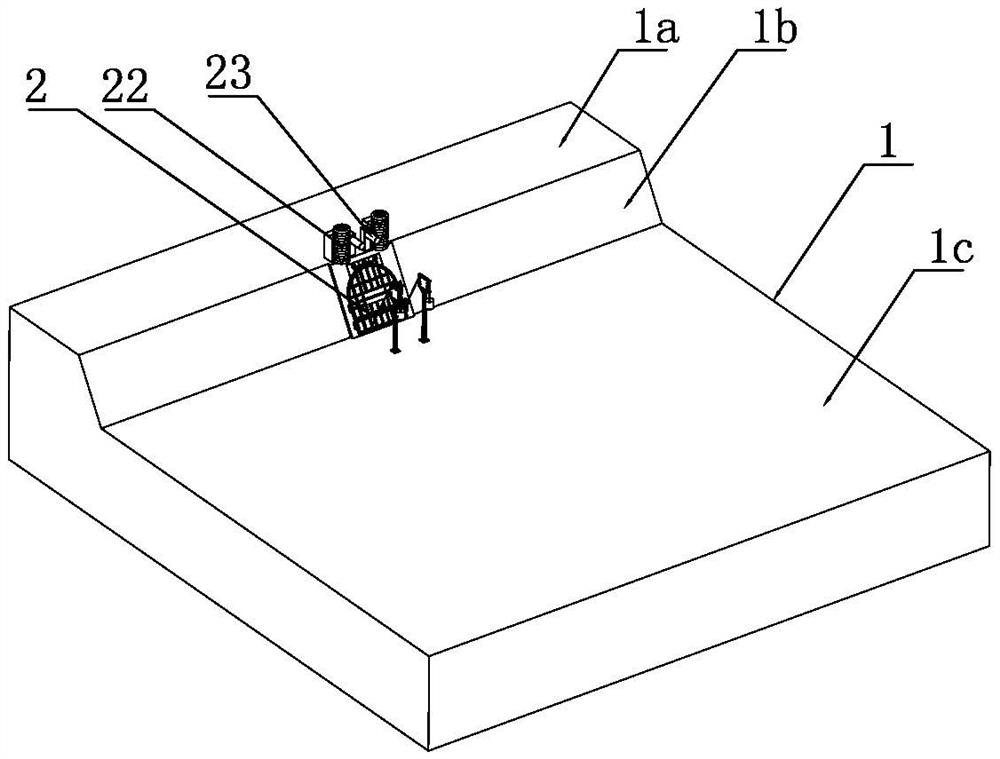

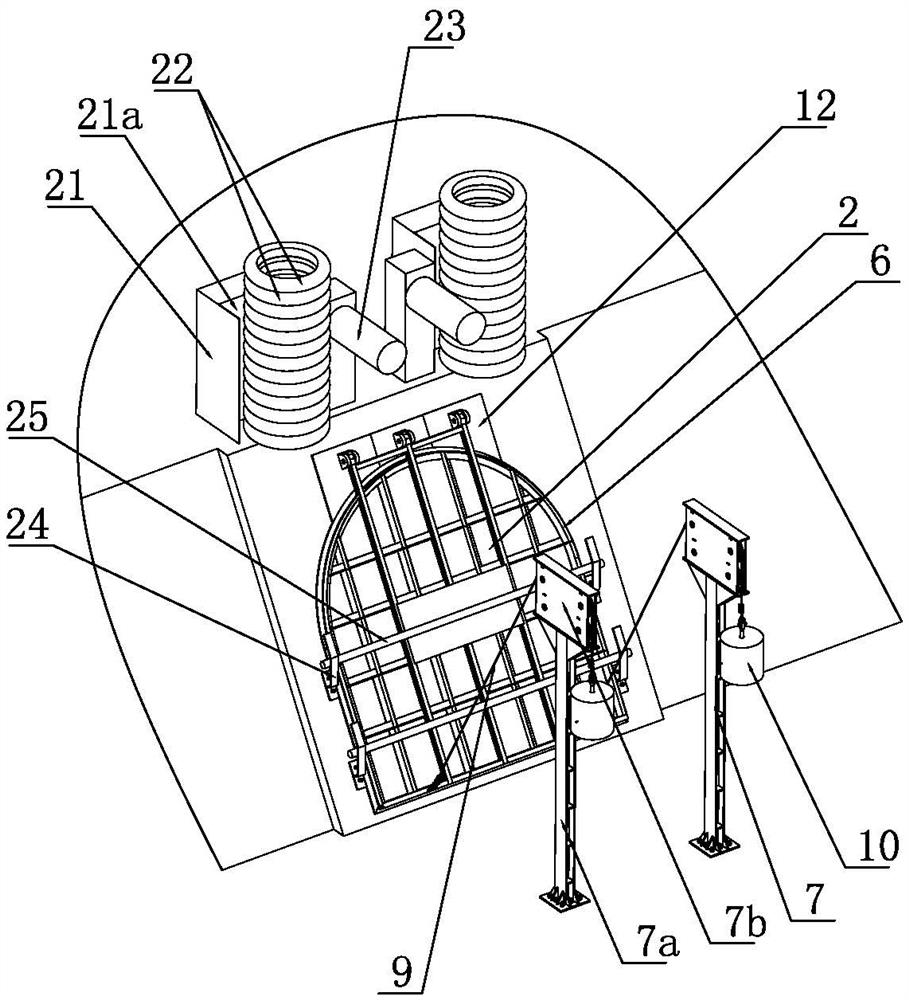

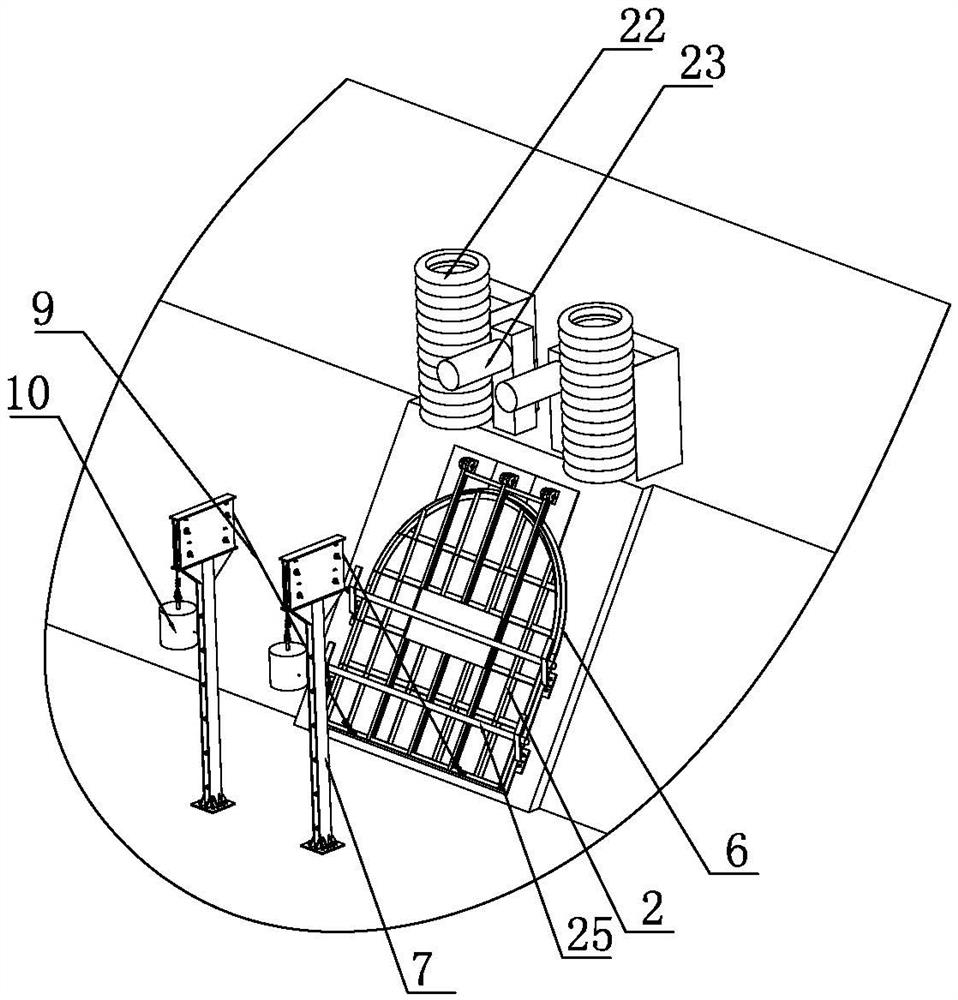

[0050] like Figure 1-20 As shown, it is a self-complex inclined shaft pressure relief and explosion-proof device for safe production of coal mines, including infrastructure 1, and a mine shaft is opened inside the infrastructure 1, and the mine shaft is connected with at least one pressure relief channel 3 and a fan channel 4, and the pressure relief channel 3 A door frame 6 is correspondingly arranged around the opening, an explosion-proof door 2 is arranged corresponding to the door frame 6, the top of the explosion-proof door 2 is hinged with the door frame 6 through a hinge, and at least two left and right corresponding mounting brackets 7 are arranged corresponding to the explosion-proof door 2 , each mounting bracket 7 is rotatably provided with a number of guide pulleys 8, the explosion-proof door 2 is connected with a number of wire ropes 9 that are parallel to each other, each wire rope 9 is set in a one-to-one correspondence with each mounting bracket 7, and the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com