Coal-fired unit screen type superheater over-temperature control system based on wall temperature prediction, and method thereof

A coal-fired unit and control system technology, applied in superheating temperature control, steam superheating, lighting and heating equipment, etc., can solve the problem of not being able to give boundary parameters, not complying with online calculation, and not being able to participate in real-time closed-loop control of power station wall temperature, etc. problems, to achieve the effect of reducing the risk of screen over-wall temperature overheating, assisting in adjusting the flow of flue gas, and enriching automatic control functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

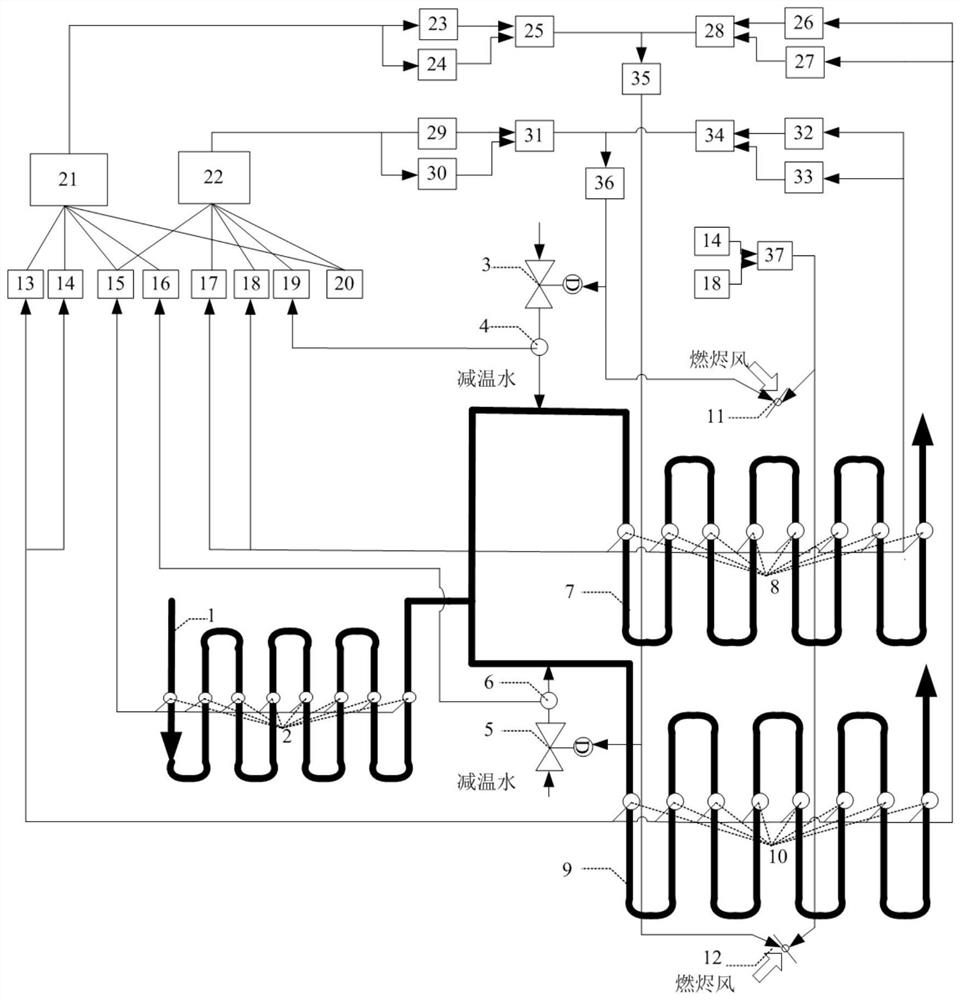

[0058] Such as figure 1 As shown, the present invention is based on the overtemperature control system of the coal-fired unit’s superheater overheating control system based on wall temperature prediction. 3 and the left primary desuperheating water flow sensor 4 are connected to the left side superheater 7, and the right side passes through the right primary desuperheating water regulating valve 5 and the right primary desuperheating water flow sensor 6 is connected to the right side superheater 9 are connected; low-temperature superheater 1 is arranged with multiple low-temperature superheater wall temperature sensors 2, left-side superheater 7 is arranged with multiple left-side superheater wall temperature sensors 8, and right-side superheater A plurality of wall temperature sensors 10 of the right side-type superheater 9 are arranged on the device 9; left-side combustion wind baffles 11 and right-side side-type superheaters 9 are respectively arranged on the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com